Understanding the components of your equipment is crucial for ensuring its longevity and optimal performance. Each piece serves a specific function, and knowing how they fit together allows for easier repairs and maintenance. Proper familiarity with these elements can save time and reduce the likelihood of costly breakdowns.

Detailed visual guides provide a clear view of how each part interacts, helping users identify any worn or damaged pieces quickly. This knowledge is invaluable for both professional technicians and DIY enthusiasts who seek to keep their tools in top shape.

By familiarizing yourself with the exploded views and understanding the role of each component, you can confidently carry out maintenance tasks, troubleshoot issues, and make necessary replacements. Whether you’re working on a small project or a more complex repair, having this reference on hand is an essential step toward efficient equipment care.

Stihl HT 131 Parts Overview

When working with any tool, it’s essential to know the various components that make up its structure. Each element plays a vital role in ensuring smooth operation, whether it’s the engine, cutting mechanism, or control system. Understanding these individual parts helps in performing necessary maintenance and addressing potential issues effectively.

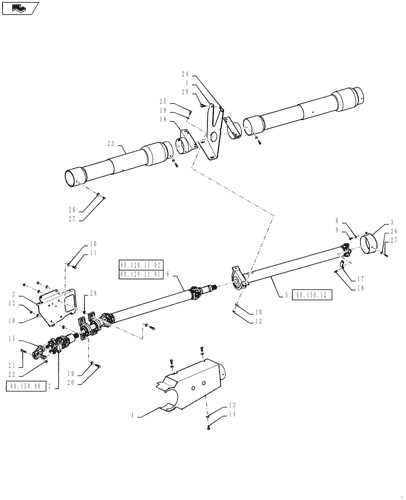

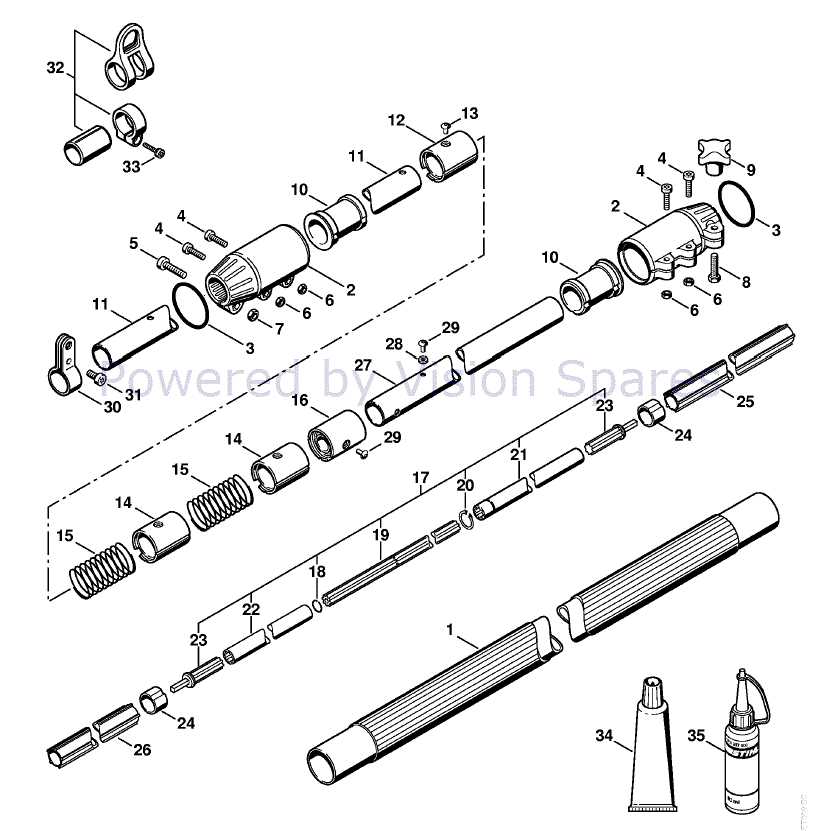

For tools designed to handle heavy-duty tasks, such as tree trimming and branch cutting, the assembly consists of a variety of mechanical and electrical elements. These range from the motor housing to the drive shaft, with each part designed for specific functions. Familiarizing yourself with these components will allow you to identify problems and address them before they lead to major failures.

By reviewing the different sections and their connections, users can gain a clearer picture of the tool’s construction and operation. This knowledge is crucial for maintaining its efficiency and preventing unnecessary damage. Keeping track of individual components also helps in ensuring that the equipment remains in good working order for a longer period.

Identifying Key Components for Maintenance

Proper upkeep of any tool requires a solid understanding of its core components. Identifying the key elements that require regular checks ensures that the equipment runs smoothly and lasts longer. A proactive approach to maintenance reduces the risk of malfunction and increases overall efficiency.

Engine and Power Transmission

The engine is the heart of the equipment, converting fuel into energy to drive the various mechanisms. Regular inspection of the motor, along with the power transmission system, is essential to ensure that all parts are functioning as they should. Look out for any signs of wear or damage in the engine housing, ignition system, and drive components, as they are critical to performance.

Cutting Mechanism and Housing

The cutting mechanism is directly involved in the performance of the tool, and maintaining its sharpness and alignment is crucial. Inspecting the blade or cutting attachment regularly can prevent unnecessary strain on the engine. Additionally, the housing that holds these parts should be checked for cracks or deformities that could affect the tool’s handling and efficiency.

Understanding the Stihl HT 131 Exploded Diagram

Exploded views provide an insightful breakdown of the various components within a tool, offering a clear illustration of how each part fits together. By examining these detailed visual guides, users can gain a better understanding of the structure and assembly, making it easier to troubleshoot and maintain the equipment.

In an exploded view, all elements are displayed separately yet in relation to one another, highlighting the individual roles they play in the overall functioning of the tool. This allows users to identify potential issues and pinpoint parts that may need attention.

- Visualizing Component Placement: The exploded view shows how different parts interconnect, which is essential for understanding their function within the system.

- Detecting Worn or Damaged Parts: By clearly showing each element, users can quickly spot any broken or degraded components that require replacement.

- Easy Assembly and Disassembly: For those performing maintenance, this view helps in assembling or disassembling the tool correctly, reducing errors and saving time.

Having access to a well-detailed exploded view can significantly enhance the user’s ability to maintain their equipment, ensuring smooth operation and extending its service life.