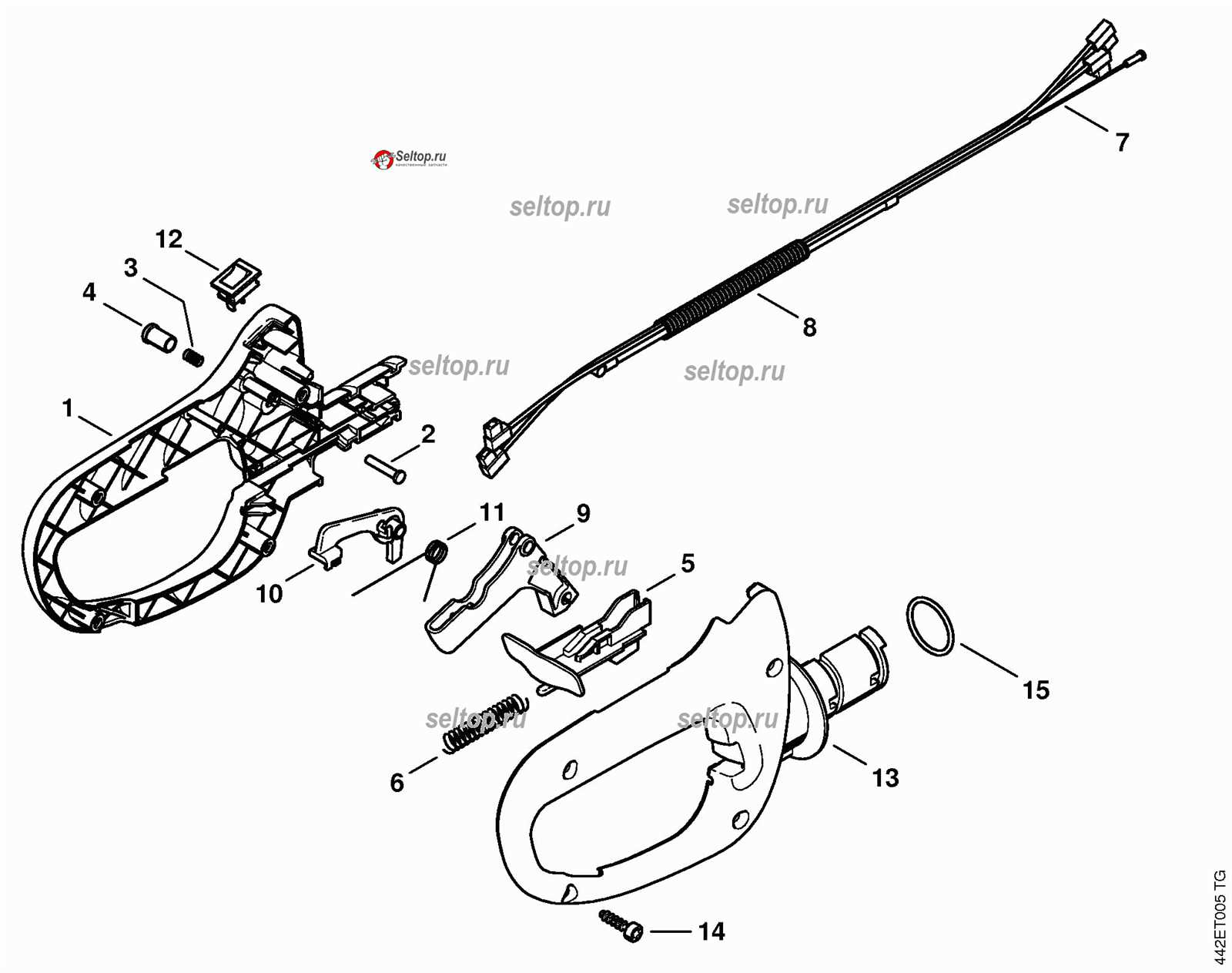

When maintaining or repairing equipment, it’s essential to have a clear understanding of the internal structure. Knowing the function of each part helps in troubleshooting and ensures smooth operation. A well-detailed illustration of these parts can significantly simplify this process.

Detailed schematics serve as a helpful guide, allowing users to identify each component and its specific role. With such resources, it becomes easier to assess wear and tear, locate potential issues, and ensure proper assembly. This approach contributes to longer-lasting performance and smoother maintenance.

Familiarizing yourself with the component layout is key to achieving optimal results in repair tasks. Whether you’re replacing a part or inspecting for damage, having a visual reference is invaluable. It enables a quicker, more efficient diagnosis, reducing the time spent on each task.

Understanding the Breakdown of Components

Knowing how to read and interpret the layout of a tool’s inner workings is crucial for effective maintenance and repair. A visual guide that highlights each individual element allows for better identification of each part and its function within the overall system. This approach makes troubleshooting and repairs much easier, as each piece is clearly outlined for quick reference.

Key Features and Functions

Each component in the system plays a specific role, contributing to the efficient performance of the entire tool. Understanding how these parts interact helps in diagnosing potential problems. By focusing on the primary elements and their functions, users can better assess wear and detect issues before they become major problems.

Efficient Maintenance and Troubleshooting

Once familiar with the layout, it’s easier to spot which part needs attention. With this understanding, users can perform regular checks and address any issues swiftly. This not only ensures the longevity of the tool but also guarantees safe and reliable use over time. Efficient identification of malfunctioning parts allows for faster repairs, minimizing downtime and enhancing overall productivity.

Understanding the Breakdown of Components

Having a comprehensive visual representation of machinery is crucial for understanding its internal structure and the function of each element. This reference is essential when diagnosing issues or conducting repairs. A clear and accurate schematic aids in identifying individual components, their placement, and how they interact with one another, facilitating a more efficient troubleshooting process.

Key Elements of the System

Each section of the system plays a vital role in the machine’s overall performance. From the motor housing to the cutting mechanisms, each component has a specific task that contributes to the functionality. A thorough overview of these parts helps in understanding how each piece works together to ensure smooth operation. Recognizing wear patterns and possible failure points can prevent unnecessary downtime.

Using the Schematic for Maintenance

By referring to an organized breakdown, users can pinpoint which parts need replacement or adjustment. Visual guides often provide essential details like part numbers and placement, making it easier to order and replace components. Regular maintenance becomes more manageable when equipped with an understanding of the system’s layout, ensuring all pieces are correctly aligned and functioning properly.

How to Use the Breakdown Effectively

To achieve a smooth repair or maintenance process, it’s important to leverage a well-structured reference. Understanding how to interpret such guides can significantly improve efficiency and accuracy. By identifying individual components and their roles, users can quickly determine what needs attention and avoid common mistakes.

Identifying Key Components

The first step in using a schematic effectively is recognizing the main sections. Carefully study the layout to familiarize yourself with each part and its placement. This understanding helps you identify which pieces require inspection or replacement. Knowing the function of each element allows for quicker decisions during the repair process.

Locating and Replacing Components

Once you’ve identified the necessary parts, the next step is to locate them in the schematic. Most visual guides provide clear markings for part numbers and their exact positions within the assembly. This makes it easier to order replacements or make repairs. Ensuring each component is correctly installed is crucial for optimal performance.