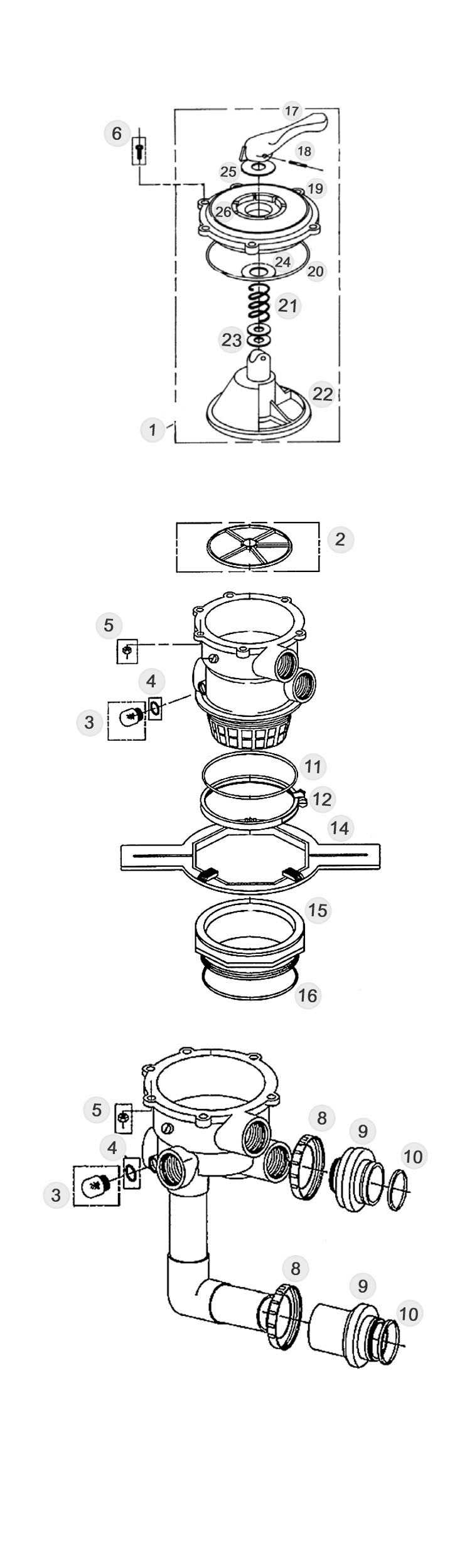

Understanding the internal structure of your filtration system is crucial for ensuring its efficient operation. Each element plays a vital role in maintaining proper functionality, and recognizing these components can help in both troubleshooting and regular upkeep.

Proper knowledge of the individual elements enables users to address common issues, perform timely replacements, and extend the lifespan of their equipment. Recognizing wear and tear in specific sections can also prevent costly repairs in the future.

Familiarizing yourself with how each piece functions together will allow for a smoother operation and easier management, ensuring your system continues to run smoothly without interruptions. This guide offers an overview to help you navigate through the key aspects of your setup with confidence.

Understanding Key System Components

To ensure optimal performance, it is essential to grasp the role of each element within your filtration setup. Every component serves a specific function that contributes to the overall efficiency of the system. Understanding how these parts interact helps in troubleshooting and enhances the ability to perform maintenance tasks effectively.

Each section of the system has a designated purpose, whether it is for filtration, circulation, or pressure regulation. By recognizing the function of each element, users can identify potential issues before they escalate into more significant problems.

Familiarizing yourself with the different elements allows for easier identification of parts that may require attention or replacement. Knowing which parts are critical for the system’s operation enables users to maintain their equipment in peak condition, preventing unnecessary downtime.

Key Parts and Their Functions

Understanding the main components of your filtration system is essential for effective maintenance and troubleshooting. Each part is designed to handle specific tasks, ensuring the entire system operates seamlessly. By identifying the role of each element, users can ensure smoother performance and prevent common issues.

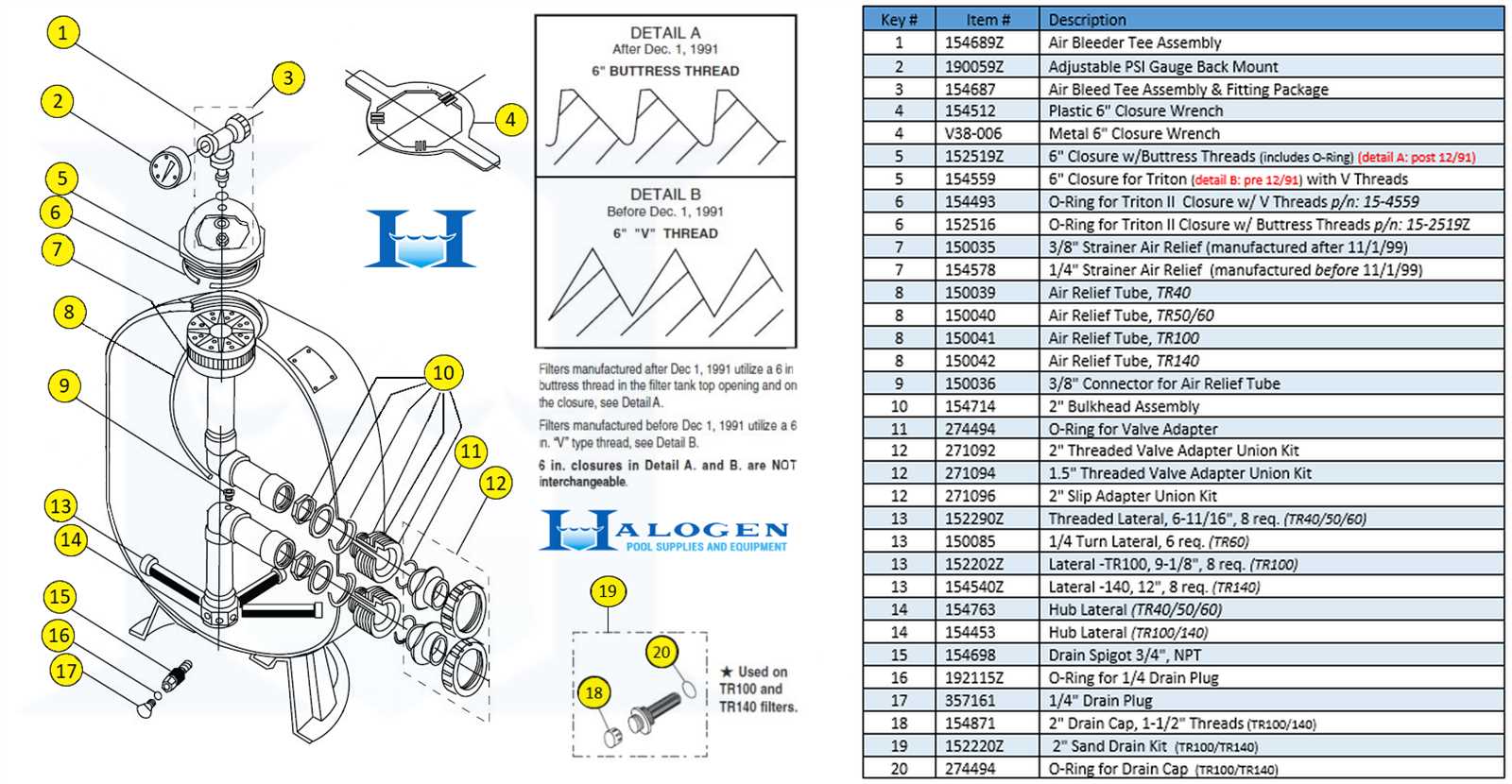

Filtration Mechanism

The filtration mechanism is responsible for removing debris and impurities from the water. It ensures that only clean water circulates through the system, maintaining optimal performance and preventing damage to other components. Regular cleaning and occasional replacement of the filtration media are necessary to maintain efficiency.

Pressure Regulation

The pressure regulation unit ensures that water flows at the correct pressure throughout the system. By maintaining consistent pressure, it prevents overworking certain components and ensures the longevity of the entire setup. Monitoring and adjusting pressure levels can prevent system malfunctions and prolong the life of the equipment.

Common Issues and Replacement Parts

Every filtration system experiences wear and tear over time. Identifying common issues early and knowing which components need replacement can save time and prevent costly repairs. Regular inspection and maintenance are key to extending the lifespan of the equipment.

Clogging and Blockages

Clogging is one of the most frequent problems that can arise. This issue typically occurs when debris accumulates in the filtration system, restricting water flow. It is essential to clean or replace the filter media regularly to prevent such blockages, ensuring smooth operation and avoiding strain on the system.

Pressure Imbalance

Pressure imbalances can result from various factors, including faulty valves or worn seals. When pressure levels are too high or too low, the system may not function correctly, leading to inefficiency or damage. Replacing worn seals or adjusting pressure settings can restore proper function and extend the system’s lifespan.