When dealing with snow clearing machinery, it’s essential to have a clear understanding of the various components involved. Each piece plays a crucial role in the overall functionality, ensuring efficiency during operations. Whether you’re a beginner or an experienced user, knowing how these elements interact with one another helps maintain the system in top condition.

Breakdown of Key Elements is vital for proper handling and troubleshooting. Familiarity with the design and function of each part allows for quicker identification of issues, leading to more effective repairs. This knowledge also contributes to smoother usage, enhancing performance during snow management tasks.

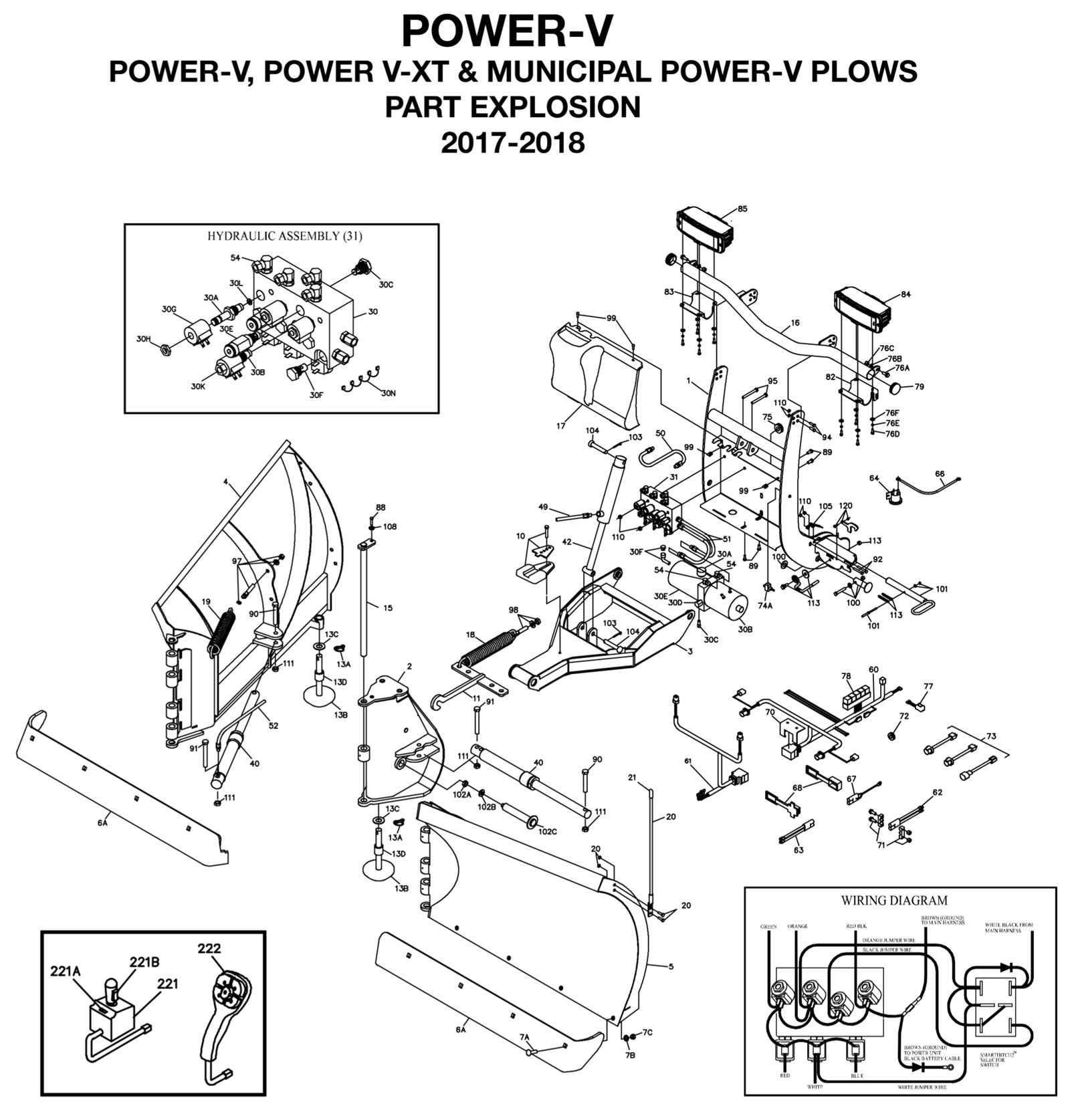

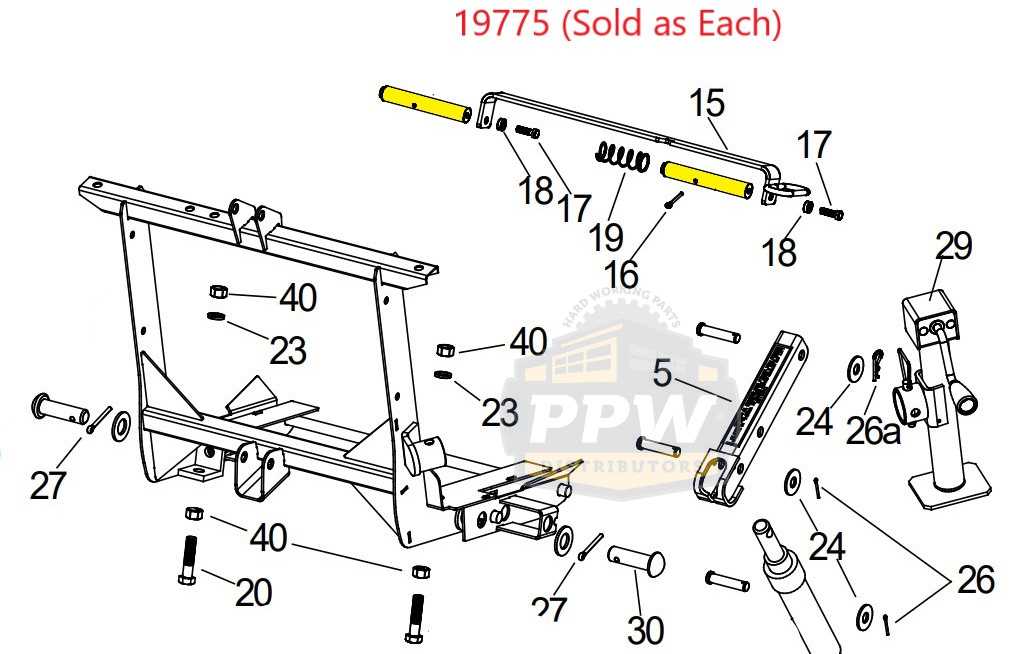

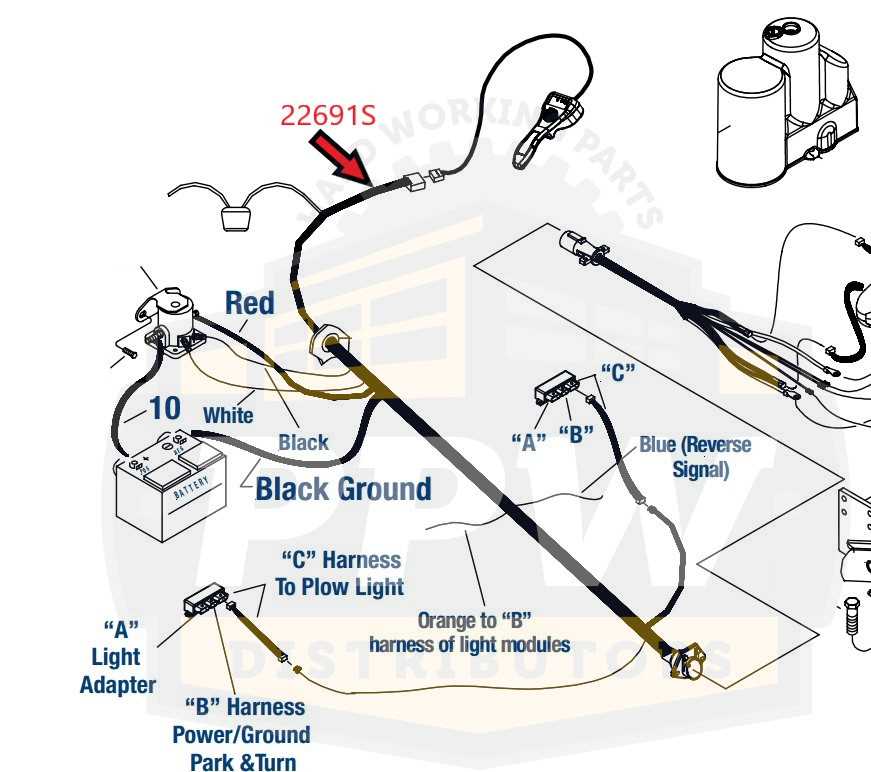

Visual Guides can greatly assist in understanding the structure of the machinery. These resources provide a clear layout, making it easier to identify each component and comprehend its specific function within the overall system. By referring to these guides, users can ensure they are working with a well-maintained setup.

Understanding the Snow Removal Equipment Components

Effective snow clearing machinery relies on a combination of carefully designed elements that work in harmony to ensure smooth operation. Each component has a specific role, contributing to the overall performance. Understanding how these pieces fit together allows users to maximize efficiency and maintain their equipment in optimal condition.

Core Elements and Their Function

The foundation of any snow-clearing setup consists of several key components, each designed to handle different aspects of the task. From the lifting mechanism to the angling systems, each part is essential for achieving the desired results. Knowing how these elements interact with one another is crucial for both effective use and troubleshooting.

Maintenance and Troubleshooting

Maintaining and repairing snow removal equipment is much easier when the user understands the layout and functions of its core components. Regular inspections and quick identification of issues can help avoid major malfunctions. A clear understanding of how the parts work together enables more efficient and cost-effective maintenance practices.

How to Read Snow Removal Equipment Layouts

Understanding the layout of snow removal machinery is key to performing maintenance and repairs effectively. Visual guides and schematics present the arrangement of components in a way that simplifies troubleshooting and identification of issues. These diagrams help users see how each element connects and functions within the system.

To properly read these guides, it’s essential to familiarize yourself with the symbols and labels used. Each part is typically marked with a unique identifier, allowing for easy reference. By following the flow of the schematic, you can identify the various sections and understand the relationships between the components, ensuring accurate repairs and adjustments.

Another important step is recognizing the color coding or numbering system that may be used to distinguish different types of components. This system helps users navigate the diagram and locate the parts they need to focus on, enhancing the efficiency of repairs and maintenance.

Tips for Maintaining Snow Removal Equipment Components

Proper care and maintenance of snow clearing machinery are essential for ensuring longevity and optimal performance. Regular upkeep can prevent major issues and reduce the need for costly repairs. By following a few simple tips, users can keep their equipment running smoothly and efficiently throughout the season.

Regular Inspections

Frequent inspections are key to identifying wear and tear before they become serious problems. Check all moving parts, such as lifting and angling mechanisms, to ensure they are functioning correctly. Lubrication of joints and other friction points is also essential for maintaining smooth operation.

Keep Components Clean

Keeping the components free from debris and buildup can prevent blockages and malfunctions. Clean all areas thoroughly after each use, especially in areas exposed to snow and salt. Rinsing off excess dirt and moisture helps prevent rust and corrosion, extending the life of the machinery.