When examining a complex mechanical system, it’s crucial to break down its essential elements to fully grasp how each part contributes to the overall function. These systems are made up of various interconnected components, each playing a specific role in ensuring smooth performance. Whether you’re a mechanic or simply curious about how things work, understanding these elements can be both informative and useful.

Each section of the system interacts with others, creating a network that supports movement and efficiency. By learning to identify and understand these crucial components, you can gain insight into maintenance needs, potential issues, and repair techniques. Recognizing how these parts operate together can improve your understanding of mechanical systems.

Knowing the function of each piece helps in troubleshooting, repairs, and regular maintenance. Through diagrams and technical illustrations, this knowledge becomes easier to visualize, making it possible to identify any areas requiring attention. This guide will explore these fundamental aspects, providing a clear overview of how the elements contribute to overall functionality.

Key Components of a Drive Shaft

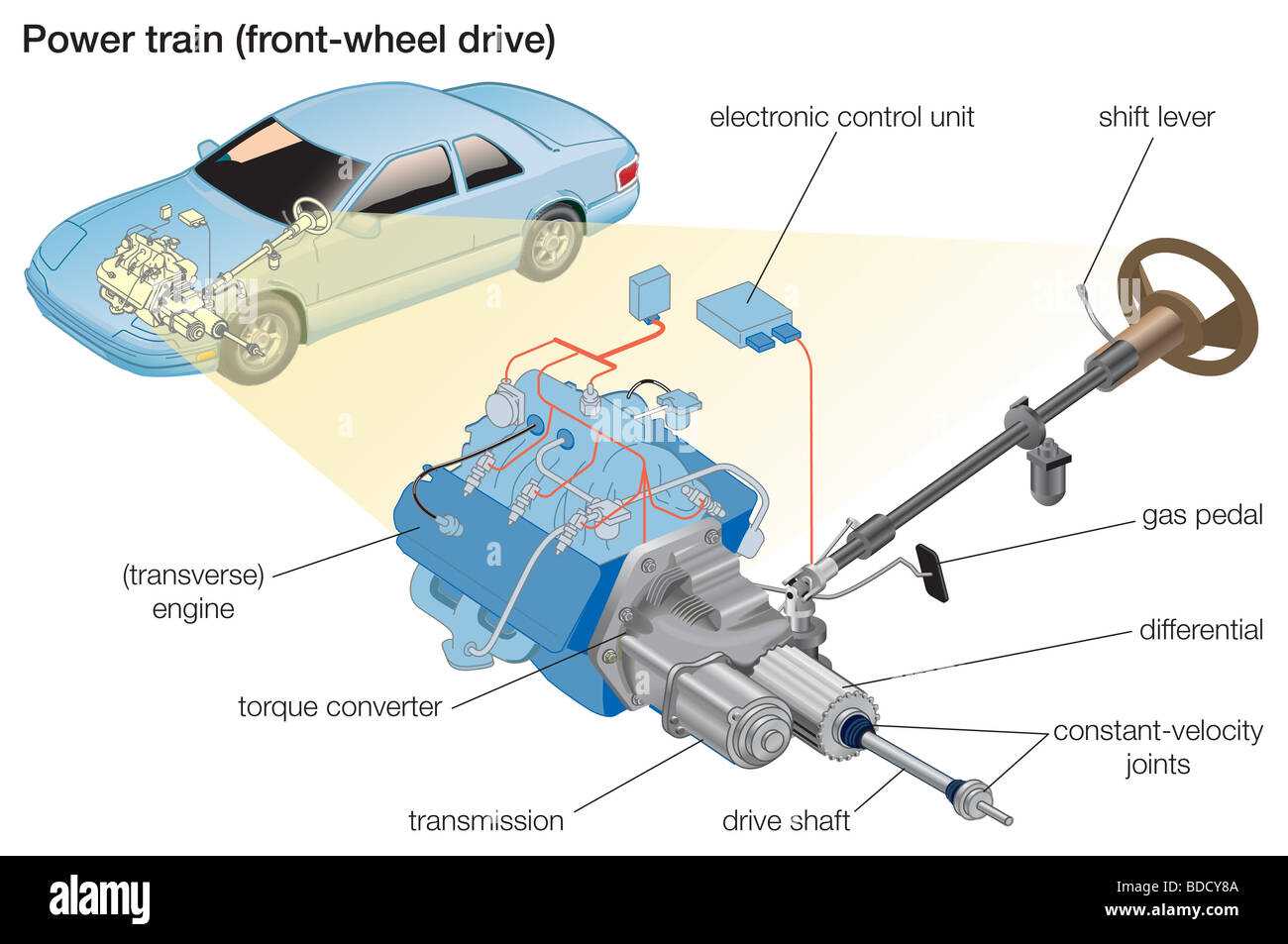

In any mechanical system designed for power transmission, certain elements are essential for ensuring smooth operation. These components work together to transfer motion from one part of the mechanism to another, enabling efficient movement. Understanding each piece of the system is crucial for proper maintenance and troubleshooting.

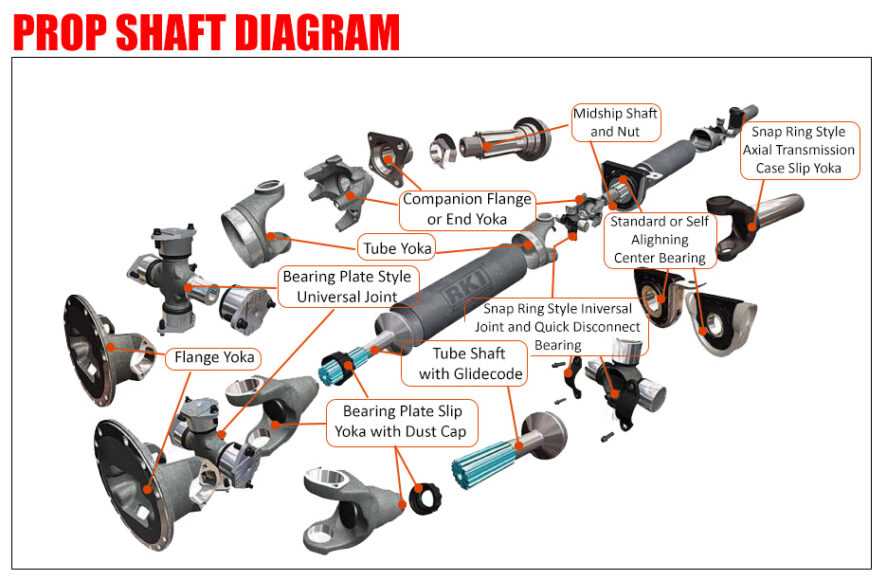

The central element in this system is responsible for transmitting rotational energy. It connects different parts of the vehicle or machine, allowing them to function in harmony. Key components of this structure include the universal joints, yokes, and couplings, each playing a distinct role in ensuring flexibility and stability during motion.

Universal joints are pivotal in maintaining the flexibility of the system, allowing parts to move independently while staying connected. Yokes, on the other hand, secure these joints in place, ensuring that they remain properly aligned. Additionally, couplings play a vital role in connecting various sections, ensuring power flows seamlessly from one segment to the next. Together, these elements create a robust network that supports efficient performance.

Understanding the Function of Each Part

In any mechanical system, each component serves a unique and vital role to ensure the system functions as intended. Recognizing the specific duties of these individual elements allows for a clearer understanding of how the entire mechanism operates. By examining their interactions, it becomes easier to identify potential issues and recognize when maintenance or repairs are needed.

Each segment is designed to contribute to the overall movement and efficiency. Some provide flexibility, enabling smooth operation even under varying conditions, while others focus on stabilizing the motion, ensuring everything stays properly aligned. Understanding the function of each piece helps in troubleshooting and making informed decisions about repairs or upgrades.

How to Read a Drive Shaft Diagram

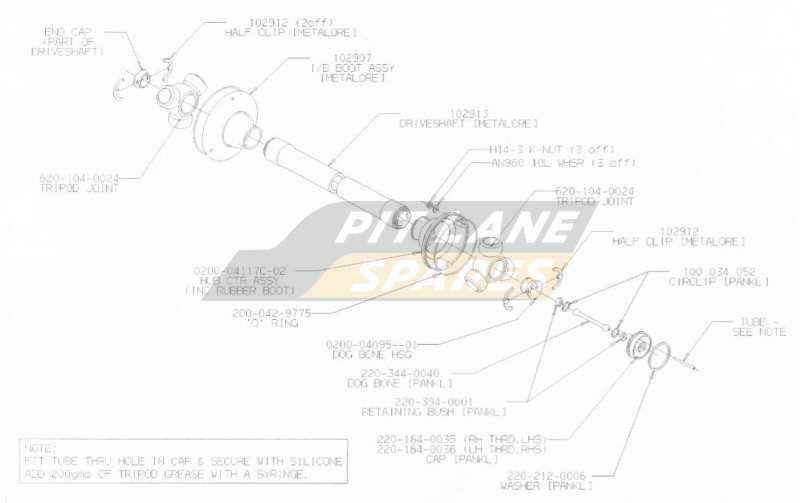

Interpreting technical illustrations requires understanding the symbols and lines used to represent different mechanical elements. These diagrams serve as a visual map, providing essential information about how various components interact and function together within a system. Properly reading these visuals is crucial for identifying the placement and connection of each segment.

Recognizing Key Elements

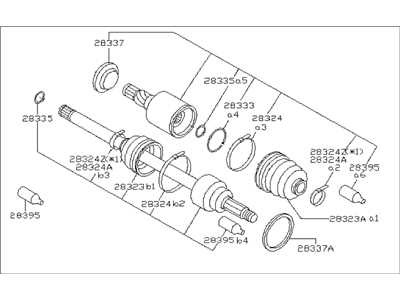

The first step in interpreting these illustrations is recognizing the individual components shown. Each part is represented by a unique symbol or shape, which helps to differentiate them. Understanding what each symbol stands for allows you to follow the flow of movement and pinpoint how the system operates.

Identifying Connections and Movements

Next, focus on the lines that connect the various components. These lines indicate the path of motion and power transfer between elements. By studying these connections, it becomes easier to understand how the system works as a whole, from the initial force application to the final movement.

Identifying Parts in the Diagram

To fully understand a technical illustration, it’s essential to recognize the different elements represented within the image. These diagrams are designed to show the interconnections and functions of various components in a mechanical system. Identifying each part correctly allows for easier comprehension of the system’s overall functionality and structure.

Key Components to Spot

- Universal joints: These elements allow flexibility and movement between connected parts.

- Yokes: These secure the joints in place and help maintain alignment.

- Couplings: These connect different sections and ensure the transfer of motion and power.

Understanding the Layout

In technical visuals, the layout of these components is vital. The positioning of each element within the system shows how they interact with one another. Pay attention to the lines and connections between parts, as these indicate how force and motion are transmitted through the system.

Common Issues with Drive Shaft Parts

In any mechanical system, wear and tear can lead to common issues that affect the performance of essential components. These problems often arise due to excessive use, lack of maintenance, or poor-quality materials. Identifying these issues early can prevent more severe damage and ensure the system operates smoothly.

Signs of Wear and Tear

Over time, certain components can show signs of deterioration, such as cracks or rust. Universal joints are particularly vulnerable, as they are subjected to constant movement and stress. If they become loose or start to exhibit play, it may indicate the need for replacement.

Misalignment and Vibration

Improper alignment can cause significant vibration issues. When the yokes or couplings become misaligned, it can lead to uneven motion and further stress on the system. This can cause discomfort, excessive noise, and even potential failure if left unchecked. Regular inspection of these connections helps to avoid such problems.