When it comes to maintaining an engine, knowing the layout of its key components is essential. A clear representation of how each part fits together can greatly aid in both troubleshooting and repairs. Having access to a well-organized schematic of the machine helps users understand the internal structure and simplifies identifying specific elements.

Identifying components within a system can often seem overwhelming, especially for those unfamiliar with mechanical work. However, a visual guide can break down the complexity and make it much easier to navigate. Each section plays a crucial role in the machine’s overall function, and understanding their relationships is key to effective maintenance.

For anyone working with mechanical systems, it’s important to familiarize oneself with the various pieces involved. Recognizing the role of each part and its location within the assembly allows for more efficient repairs and can prevent unnecessary damage. Such a schematic offers both clarity and confidence when performing tasks on the engine.

Understanding the Kohler Command Pro 25 Parts

Properly maintaining an engine requires a clear understanding of its various components and their specific functions. By recognizing the essential pieces within the system, users can ensure that everything works together smoothly and address issues as they arise. Familiarity with each part’s role will improve both troubleshooting and general upkeep.

Engine Assembly Overview

The assembly includes several vital components that work in harmony to generate power. From the fuel system to the ignition components, each element has its distinct function. Understanding how these components interact is crucial for diagnosing performance issues or ensuring the longevity of the machine.

Essential Maintenance Parts

When performing regular maintenance, some parts play a more prominent role than others. Elements like filters, belts, and spark plugs are essential to keep the engine running efficiently. Knowing where these components are located and how they affect overall performance will make servicing tasks much easier.

Key Components of the Engine Assembly

An engine is a complex system made up of various elements that work together to create the necessary power. Understanding these key components helps in ensuring efficient performance and ease of maintenance. Each section within the assembly is designed to perform a specific task, contributing to the overall functioning of the engine.

Below are the primary components typically found in the assembly:

- Fuel System – This section ensures that fuel is properly delivered to the engine for combustion.

- Ignition System – Responsible for igniting the air-fuel mixture to start the engine and maintain smooth operation.

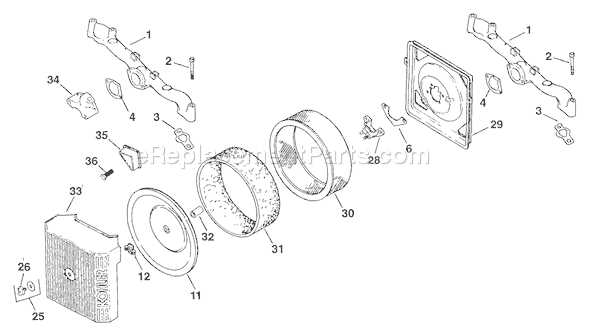

- Cooling System – Prevents the engine from overheating by regulating temperature.

- Lubrication System – Keeps the moving parts of the engine well-lubricated to reduce friction and wear.

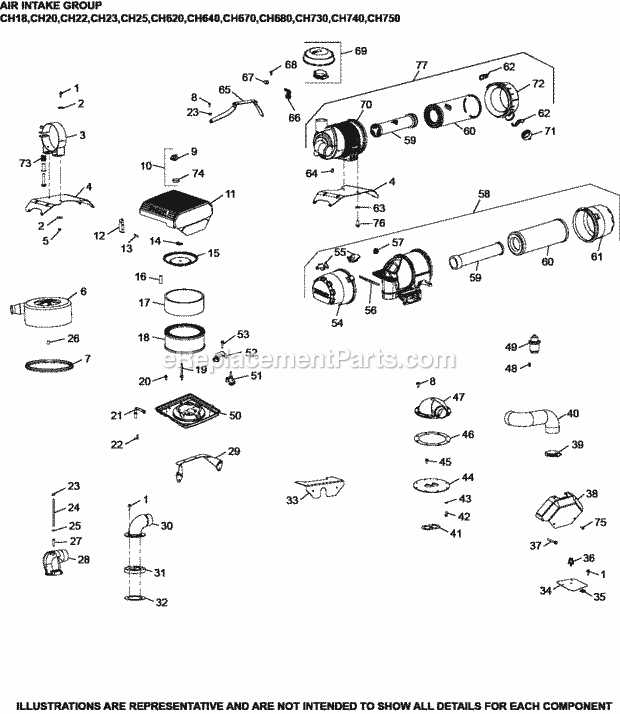

- Air Intake – Supplies the engine with the necessary air for combustion.

- Exhaust System – Directs gases produced during combustion out of the engine to ensure proper ventilation.

Each of these systems must function correctly for the engine to run smoothly. Regular inspection and maintenance of these components ensure long-lasting performance and reliable operation.

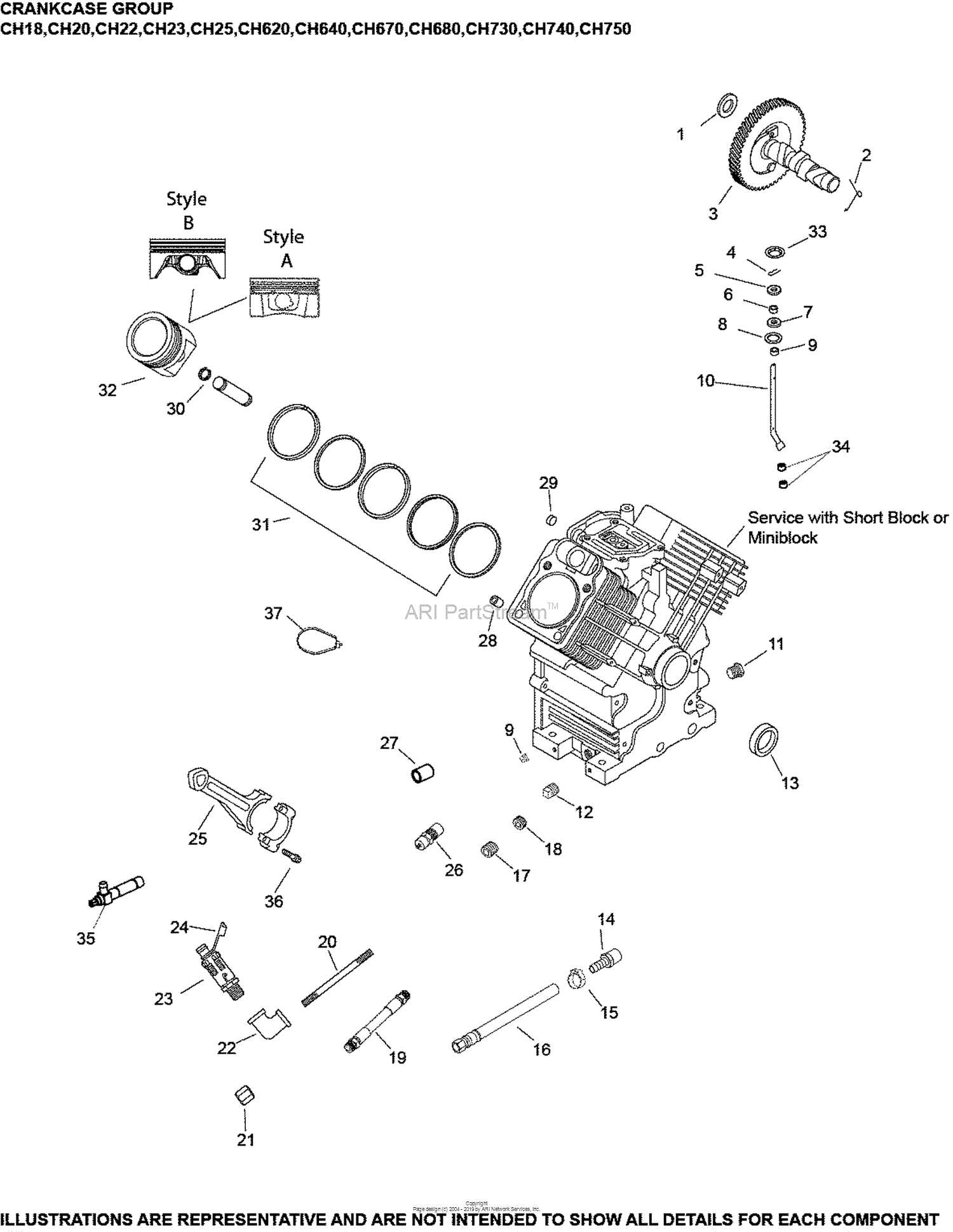

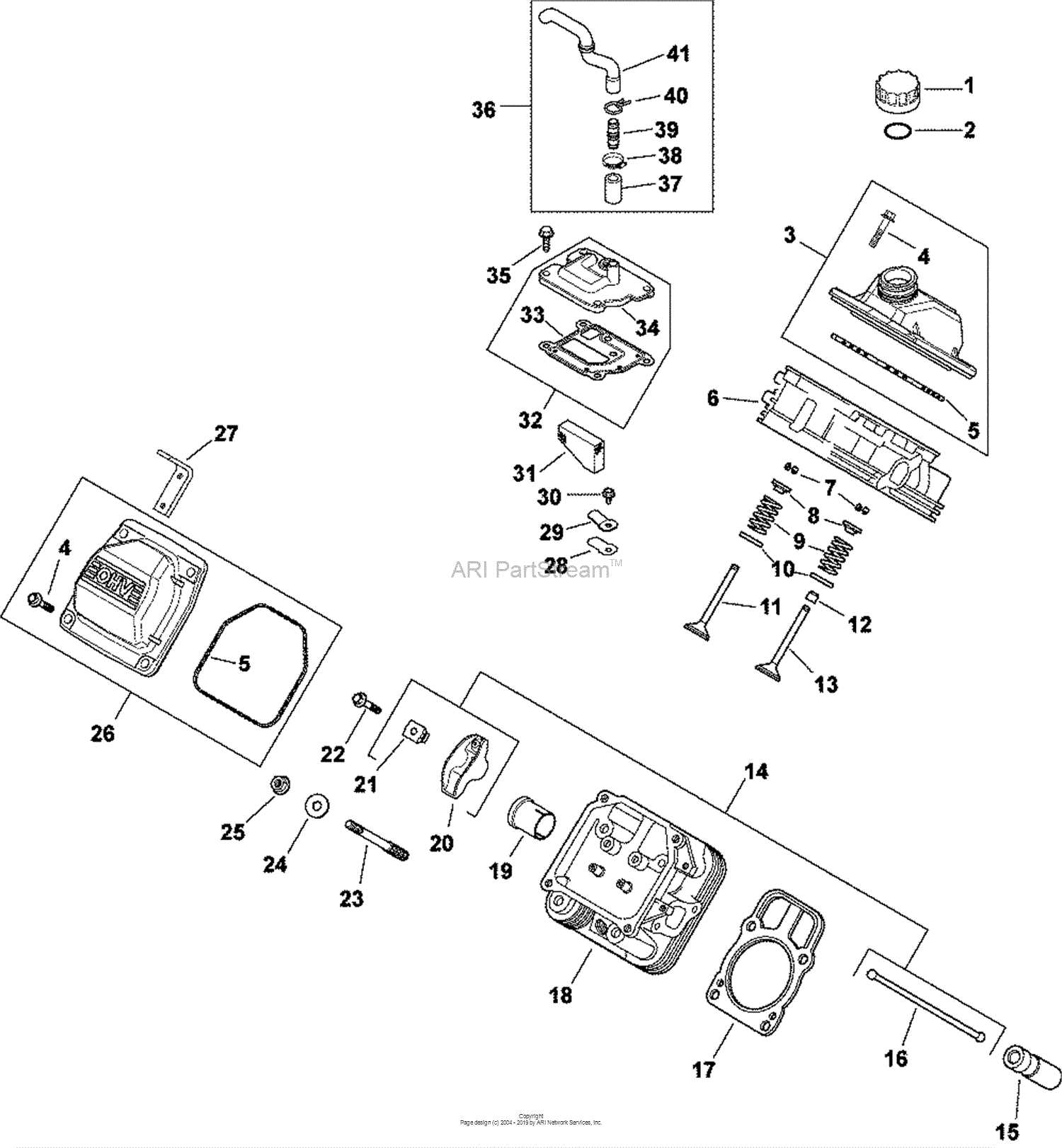

How to Read the Parts Diagram

Understanding how to read a visual representation of an engine’s components is crucial for maintenance and repairs. These illustrations provide a clear view of where each part is located and how it interacts with others. By interpreting these images correctly, users can easily identify and replace faulty components, ensuring proper functionality.

The diagram typically uses labels, lines, and symbols to represent different elements and their connections. Each part is often numbered or marked with a unique identifier, making it easier to locate within the assembly. Additionally, some visuals may include detailed notes or instructions that explain the purpose of each part and offer guidance on how to replace or service it.

Once familiar with the layout, users can quickly refer to the diagram during inspections or when troubleshooting issues. Knowing how to navigate these visuals will streamline maintenance tasks and help prevent unnecessary repairs by ensuring that each component is functioning as it should.

Step-by-Step Guide for Identification

Identifying engine components accurately is essential for efficient maintenance and repair. By following a systematic approach, you can easily locate and recognize key parts within the system, ensuring smooth functionality. This step-by-step guide simplifies the process, allowing you to pinpoint the necessary elements with ease.

Step 1: Review the Visual Layout

The first step is to carefully examine the provided visual layout. Look for clear labels or markings on each component, as these often provide essential information for identification. Take note of any numbers, symbols, or notations that correspond to specific parts, as these are your primary reference points during the process.

Step 2: Cross-Reference with the Manual

Once you have a basic understanding of the layout, cross-reference the components with the product manual or parts catalog. This will help verify the exact function and name of each part. Ensure that the part numbers match those in the guide, and check for any additional information on maintenance or replacement.

By following these steps, you can efficiently identify and address any issues within the engine system, ensuring proper maintenance and preventing unnecessary breakdowns.

Maintaining Your Engine

Proper maintenance is essential for ensuring the longevity and optimal performance of your engine. Regular care and inspection of its components can prevent common issues and extend its operational life. By understanding the key maintenance tasks, you can keep your engine running smoothly and avoid costly repairs.

Routine checks should include tasks such as changing the oil, cleaning or replacing filters, inspecting belts and hoses, and ensuring that all moving parts are properly lubricated. Monitoring the condition of spark plugs and the fuel system is also critical for maintaining efficient operation. Regular maintenance not only improves performance but also helps avoid unexpected failures during use.

By committing to a maintenance schedule and addressing issues promptly, you can ensure that the engine continues to deliver reliable power and service for years to come.