When dealing with complex cooling equipment, it’s crucial to understand the intricate system of interconnected elements that ensure efficient operation. Each component plays a significant role in the functionality of these machines, and knowing how they work together can help prevent issues and ensure smooth performance.

Familiarity with the key elements of these systems provides valuable insights into troubleshooting and maintaining optimal efficiency. The ability to identify and interpret the schematics of these systems will empower users to better care for and repair their equipment.

By analyzing these systems carefully, owners and technicians can enhance the longevity and reliability of their cooling units. This knowledge not only improves maintenance but also helps in making informed decisions when repairs or replacements are necessary.

Understanding True Refrigeration System Components

Cooling systems are made up of various crucial elements, each serving a specific function to ensure that the equipment operates smoothly. A detailed understanding of these components is essential for both users and technicians to maximize efficiency and address any issues that may arise. Each part interacts with others to regulate temperature, maintain pressure, and facilitate the overall process of keeping items at the desired temperature.

Main Components in Cooling Systems

Several key components contribute to the overall functionality of cooling equipment. Recognizing their role and how they interconnect helps in better maintenance and troubleshooting. Here are the main elements to understand:

- Compressor: The heart of the system, responsible for circulating refrigerant throughout the unit.

- Evaporator: This component absorbs heat from the air and facilitates cooling by turning liquid refrigerant into gas.

- Condenser: It releases the heat absorbed by the evaporator and returns the refrigerant to liquid form.

- Expansion Valve: Regulates the flow of refrigerant into the evaporator, ensuring optimal pressure and temperature levels.

How Components Work Together

Each part of the system works in harmony to perform the cooling function effectively. The compressor pumps refrigerant through the system, which then moves through the condenser and evaporator. The interaction of these components ensures that heat is absorbed and expelled in the proper sequence, maintaining the correct internal temperature.

Understanding how these components interact allows for better troubleshooting and system care, leading to fewer breakdowns and prolonged lifespan for the equipment.

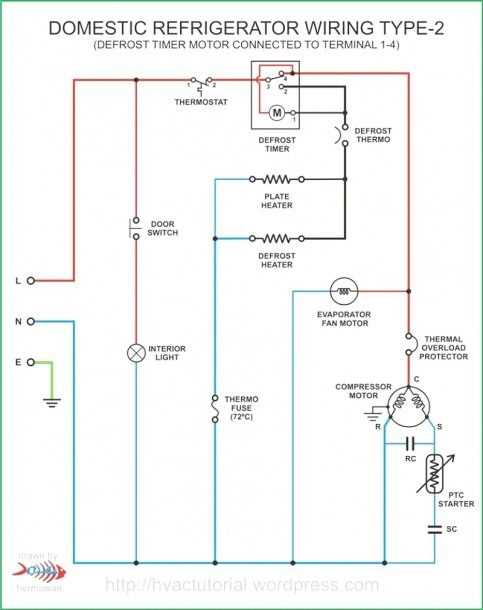

How to Read True Refrigeration Diagrams

Understanding system schematics is an essential skill for anyone working with cooling equipment. These technical drawings provide a visual representation of how the components are interconnected and how they function together. Learning to interpret these schematics enables technicians to troubleshoot, perform repairs, and ensure proper system operation with greater ease and accuracy.

Key Elements to Identify in Schematics

When analyzing technical diagrams, it’s important to recognize the symbols and lines that represent various components and connections. Here are some of the key elements to look for:

- Symbols: Different shapes and icons are used to represent specific parts, such as compressors, valves, and fans. Familiarizing yourself with these symbols will help you decode the diagram faster.

- Lines: Solid and dashed lines indicate different types of connections, such as electrical circuits or refrigerant pathways. Understanding these will give you insights into how parts are linked and interact.

- Labels: Proper labeling of components and connections is crucial. Pay attention to part names, numbers, and other identifiers that can guide you in identifying each piece of the system.

Interpreting the Flow of the System

The schematics are designed to illustrate how the system works by showing the flow of refrigerant or air through different components. By following the lines and flow direction, you can trace the sequence in which the system operates, from intake to discharge. This understanding is invaluable for diagnosing issues such as poor cooling performance or leaks.

With regular practice and familiarity, reading these diagrams becomes second nature, making maintenance and repair tasks more efficient and accurate.

Maintaining Your True Refrigeration Parts

Proper maintenance of your cooling equipment ensures that it operates at peak efficiency and extends its lifespan. Regular checks and upkeep can prevent costly repairs and system breakdowns. Knowing the correct procedures for cleaning, inspecting, and replacing key components will help avoid unnecessary downtime and maximize the performance of your unit.

Routine Inspections and Cleaning

Regularly inspecting and cleaning the system is essential to keep everything functioning properly. Dust, dirt, and debris can accumulate on critical components, affecting performance and leading to overheating or malfunctions. Follow these steps for effective maintenance:

- Check for Leaks: Look for any signs of refrigerant or air leaks, which can reduce efficiency and damage the system.

- Clean Components: Ensure that coils, fans, and vents are free from debris. Use a soft brush or vacuum to remove dirt.

- Examine Connections: Inspect electrical and refrigerant connections for signs of wear or corrosion that could affect system performance.

Replacing Worn Components

Over time, parts such as seals, fans, or compressors can wear out, leading to decreased efficiency or failure. It is important to replace these parts as needed to maintain optimal functionality. Pay attention to the manufacturer’s recommendations for part replacement and always use high-quality, compatible components.

By staying on top of these maintenance tasks, you can keep your cooling system in top shape and avoid costly repairs down the line.