Maintaining your lawn equipment is crucial to ensuring it operates efficiently throughout its lifespan. Familiarity with the internal structure and components can greatly aid in troubleshooting and performing necessary repairs. Having a detailed view of the machine’s build can help identify worn-out or damaged parts quickly, allowing for timely replacements.

Proper knowledge of each section within the equipment not only streamlines the repair process but also enhances your ability to extend its functionality. Whether you’re a beginner or an experienced user, understanding the layout of the system is essential for effective maintenance and improved performance.

Efficiency in repairs is often linked to how well you can identify individual elements. With a comprehensive understanding of the equipment’s structure, you can make informed decisions and avoid unnecessary replacements. The right tools and information are key to keeping everything running smoothly.

Understanding the Components of Your Lawn Equipment

Every piece of lawn equipment consists of various elements that work together to ensure smooth operation. Familiarity with these components is essential for troubleshooting and maintaining optimal performance. Each part has a unique role, and understanding their functions can make diagnosing issues easier and help prevent unnecessary repairs.

Key Structural Elements

The foundation of the machine includes the main housing and structural supports. These elements are designed to protect internal components and provide stability during operation. Identifying any wear or damage to these areas is the first step in determining the health of the equipment.

Functional Components and Their Roles

Functional parts, such as the drive mechanism, motor, and controls, are crucial for the equipment’s performance. Each of these elements must be in good condition to ensure the machine operates as intended. Understanding how each part interacts within the system is vital for effective maintenance and problem-solving.

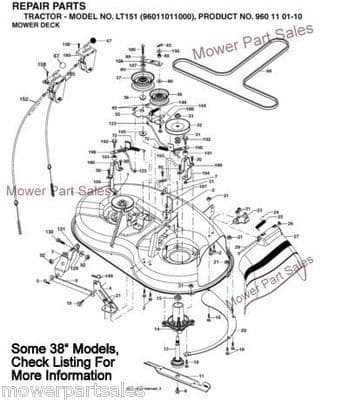

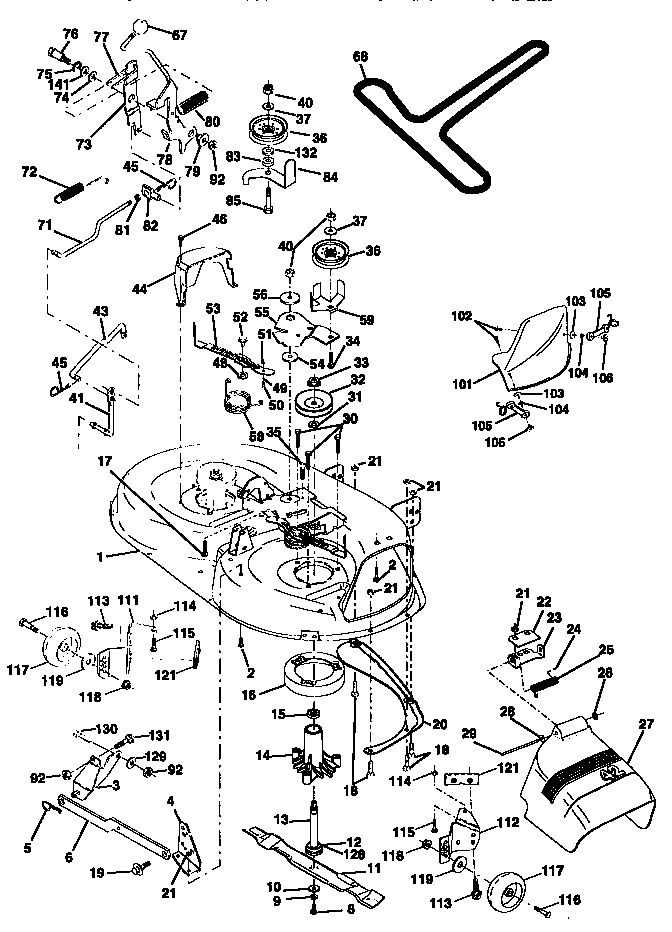

Identifying Key Parts in the Blueprint

Understanding the key components of your lawn equipment is crucial when it comes to repairs and maintenance. By familiarizing yourself with the essential elements, you can quickly identify any malfunctioning parts and determine whether they need to be replaced or repaired. A clear breakdown of each section helps in locating the source of any issues that may arise.

Essential Structural Elements

The frame and casing serve as the backbone of the entire system. These components are built to safeguard internal mechanisms while providing stability during use. Identifying cracks or damages in these areas is vital, as it ensures that the overall integrity of the machine remains intact.

Mechanical and Electrical Components

Moving parts such as the engine, transmission, and electrical connections play a key role in how the machine functions. Understanding where these components are located allows you to quickly assess whether there is any damage or need for servicing. Regular inspection of these elements will help in maintaining peak efficiency.

Common Repairs and Replacements

Over time, certain components of lawn equipment will experience wear and tear due to regular use. Identifying common issues early can save you from costly repairs and downtime. By recognizing which elements often require attention, you can keep your equipment functioning at its best.

One frequent area of concern is the drive system. Belts and pulleys often wear out, especially after prolonged use, and may need replacing to restore proper functionality. Another commonly replaced part is the blade, which can become dull or damaged, affecting the quality of cuts. Additionally, engine components such as spark plugs, air filters, and fuel lines may need periodic servicing or replacement to maintain optimal engine performance.

Electrical connections and battery-related issues are also common problems. Ensuring that wiring and connections are intact is essential for preventing malfunctions. Regularly replacing the battery can help avoid starting issues during the peak seasons.