When dealing with any type of power generator, it’s essential to have a clear understanding of its internal structure and individual components. This knowledge helps with regular maintenance, troubleshooting, and repairs, ensuring the unit functions at its best. Proper identification of each part also aids in sourcing replacements quickly when necessary.

Generators are complex machines made up of various systems working together. From the engine to the electrical components, each section plays a crucial role in generating power efficiently. By studying the layout of these elements, you can identify potential issues and prevent costly repairs down the line.

Whether you’re a professional technician or a DIY enthusiast, knowing how to navigate the components of a generator is invaluable. In this section, we will explore the key parts of a typical model and guide you through understanding their function and importance.

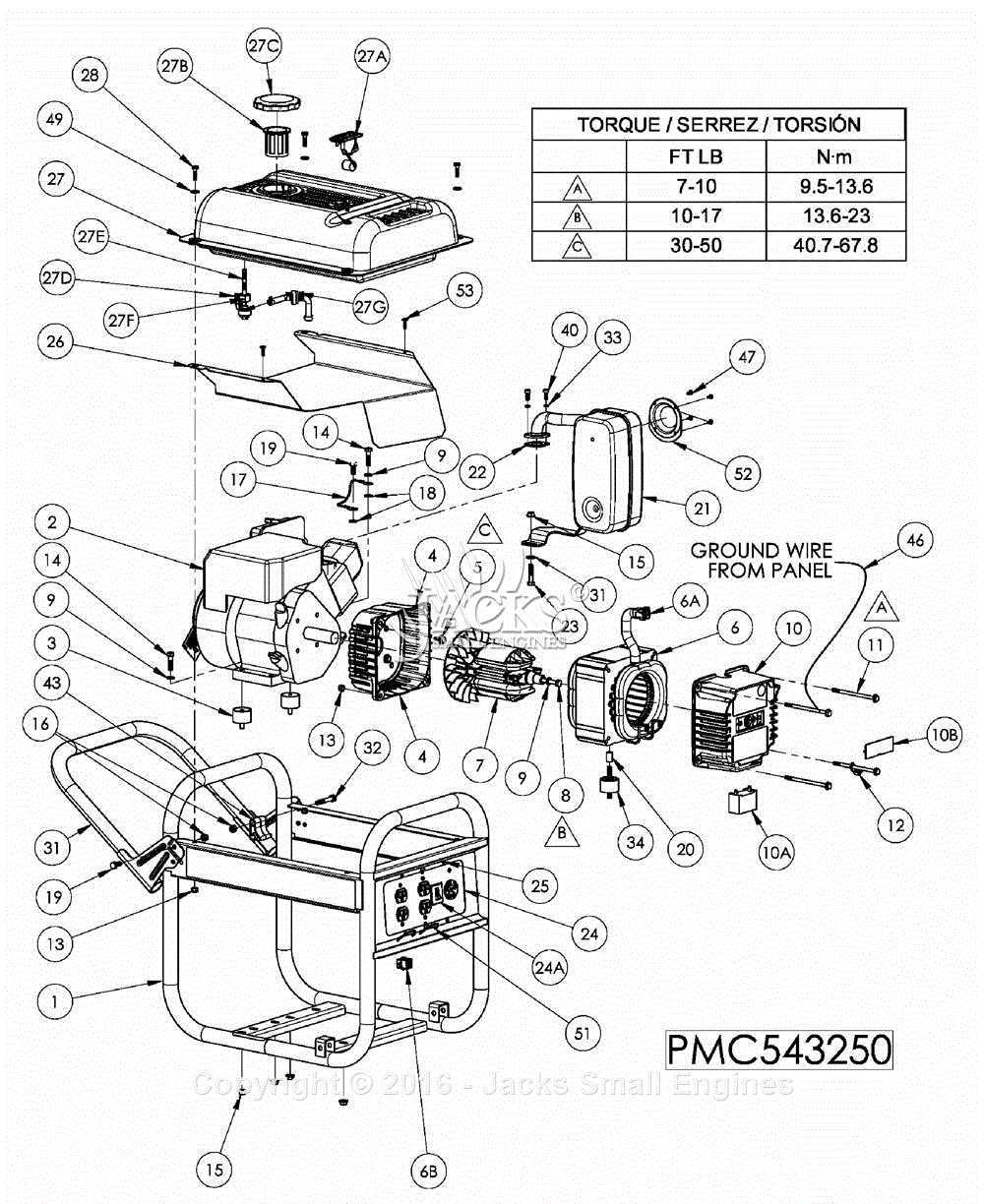

Coleman Powermate 6250 Generator Components

Generators are made up of several key elements that work together to provide reliable power. Understanding these components is crucial for proper maintenance and efficient performance. Each part, whether it’s mechanical or electrical, plays a role in ensuring the unit runs smoothly. In this section, we’ll explore the essential elements that make up a typical power generator, breaking them down into their functional groups.

Mechanical Components

The mechanical components of a generator are responsible for generating and regulating the power output. These include the engine, fuel tank, and cooling system. The engine serves as the primary source of energy, converting fuel into mechanical motion. The fuel tank stores the necessary resources, while the cooling system prevents overheating, ensuring the generator remains operational even during extended use.

Electrical Components

Electrical parts are just as vital for the smooth operation of a generator. The alternator is the key component here, converting mechanical energy into electrical power. Other electrical systems, such as the voltage regulator and circuit breakers, help manage power distribution, protect the unit from overloads, and maintain steady voltage levels for connected devices. Understanding how these systems work in tandem can help identify any potential issues that may arise during operation.

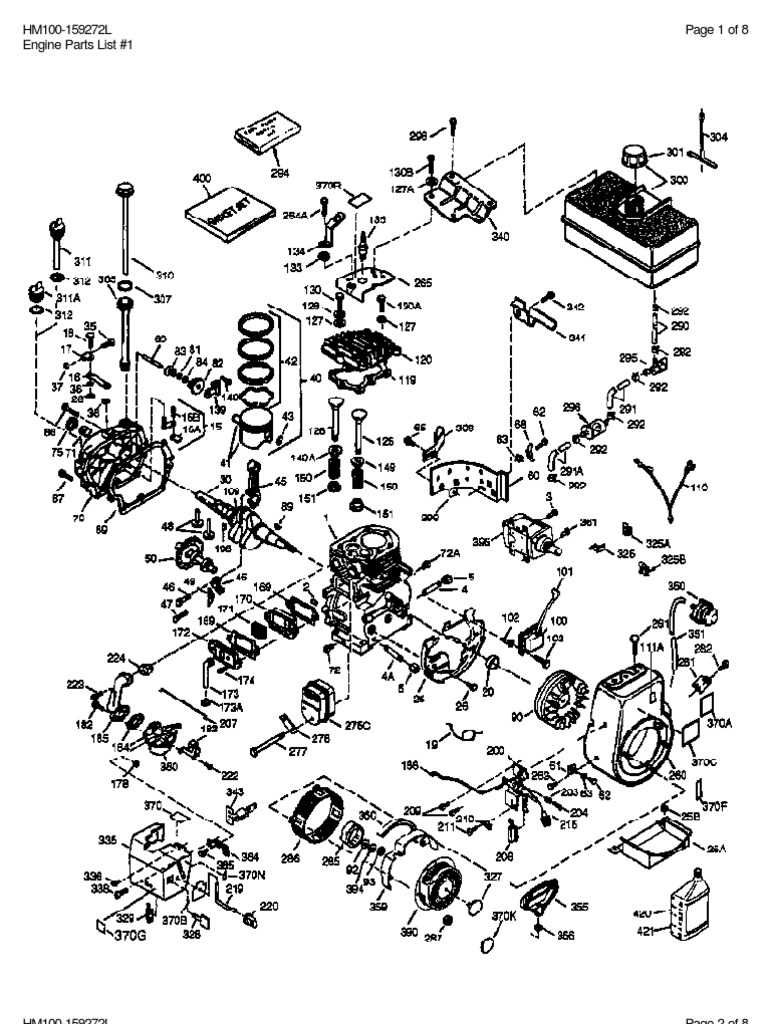

Understanding the Powermate 6250 Assembly

The assembly of a power generator consists of various interconnected systems that work together to produce and distribute energy. Each section of the unit has a specific function, contributing to the overall performance and efficiency. Understanding how these components are arranged and how they interact can be invaluable for troubleshooting and repairs.

At the heart of the assembly is the engine, which generates mechanical energy that is then converted into electrical power. This mechanical motion is transferred to the alternator, which produces the required electrical output. Surrounding these core components are systems such as fuel storage, ignition, and cooling, each playing a critical role in ensuring the machine operates without interruptions. By recognizing the layout of the assembly, it becomes easier to pinpoint potential issues and address them effectively.

Key Parts of the Coleman Powermate 6250

Understanding the essential components of a power generator is crucial for both operation and maintenance. These core elements, each with a specific function, are vital for the overall efficiency and performance of the machine. Identifying and understanding these parts ensures smooth operation and helps in the timely detection of issues.

The engine is the powerhouse of the system, converting fuel into mechanical energy that drives the alternator. The alternator, in turn, generates the electrical output necessary for powering devices. Additionally, the fuel tank holds the energy source, while the voltage regulator ensures a steady and consistent flow of electricity. Cooling and exhaust systems maintain operational efficiency by regulating temperature and safely expelling gases. Each of these critical components must function properly to maintain optimal performance.