Understanding the intricate structure of machinery is essential for efficient troubleshooting and maintenance. By gaining insight into the individual elements that make up a system, users can better comprehend its functionality and identify issues with precision. Each component plays a crucial role, and recognizing their connections is key to a smooth operation.

In this section, we will break down the essential components of the system, providing a clear view of their functions and interrelationships. This knowledge is vital for those looking to repair, modify, or optimize their equipment.

Knowing the system layout helps to pinpoint areas that may require attention or upgrades, ensuring longevity and reliability. With a solid understanding of how the elements work together, users are equipped to handle various tasks with confidence.

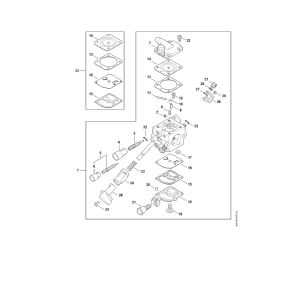

Understanding the BR430 Parts Diagram

To effectively manage and troubleshoot mechanical systems, it’s important to have a detailed understanding of how each individual component functions within the overall setup. Gaining this knowledge allows for better identification of potential problems and improvements, leading to smoother operation and longevity of the equipment. This section will guide you through the essential details of the components and their relationships.

Breaking Down the System Layout

The system consists of various elements that work in harmony. By analyzing the layout, you can identify how each part interacts and contributes to the overall functionality. Recognizing these connections will help in quickly locating faults and understanding the flow of energy or data between components.

Key Functional Relationships

Each element in the system serves a distinct role, from powering critical components to controlling key processes. Understanding these roles and their interdependencies ensures that users can diagnose issues more efficiently and maintain the equipment in optimal condition. Whether you’re conducting repairs or performing routine checks, this knowledge is crucial for accurate adjustments.

Key Components of the BR430 System

Every mechanical setup is built on several key components that collectively ensure its efficient operation. These elements are designed to work in tandem, each performing a unique function while contributing to the overall performance. Understanding the role of each part is essential for both maintenance and troubleshooting, as it helps users identify which areas need attention.

The system consists of a combination of power units, control mechanisms, and connectors that interact with each other to facilitate smooth operation. Recognizing how each component functions within this network will enable users to handle repairs or upgrades effectively. By focusing on the critical elements, one can maintain a well-functioning system for extended periods.

How to Interpret the Parts Diagram

Interpreting the visual representation of a system’s components is a crucial skill for understanding its structure and functionality. These visual aids provide a detailed map of the equipment, showing how each part fits into the larger framework. Mastering this interpretation allows for better troubleshooting and more efficient maintenance.

To properly read and understand these illustrations, focus on key symbols, labels, and connections. Each part is typically marked with clear identifiers that indicate its specific role within the system. Pay attention to the flow of energy or data between components, as this reveals how the system operates and where potential issues may arise. By becoming familiar with the layout, you can effectively diagnose and resolve problems quickly.