When maintaining or repairing your outdoor cleaning equipment, having a clear understanding of its internal structure is essential. Knowing where each component fits and how they function together can save time, effort, and potential costly mistakes. This guide will help you navigate the key elements that make up your machine and provide insight into how to identify and resolve common issues.

Efficient repair starts with a thorough understanding of the layout and function of the various internal parts. Each section plays a vital role in the overall operation, and knowing what each part does will aid in identifying any malfunctions or wear. Whether you’re a first-time user or an experienced owner, having the correct information is crucial for maintaining peak performance.

Understanding the Equipment

For effective operation and longevity of your cleaning tool, it’s important to understand its essential components and how they interact. From the motor to the nozzle, each element is designed to perform a specific function that contributes to the machine’s overall performance. Recognizing the role of each part will not only help you maintain it but also ensure smoother operation and fewer breakdowns.

The engine serves as the core power source, driving the entire system. Its efficient performance depends on the interaction with other components such as the hose, pump, and various connectors. Familiarity with the arrangement and function of these parts will give you a better understanding of how the machine operates as a whole, allowing for quicker diagnostics and more effective repairs if needed.

How to Identify Pressure Washer Parts

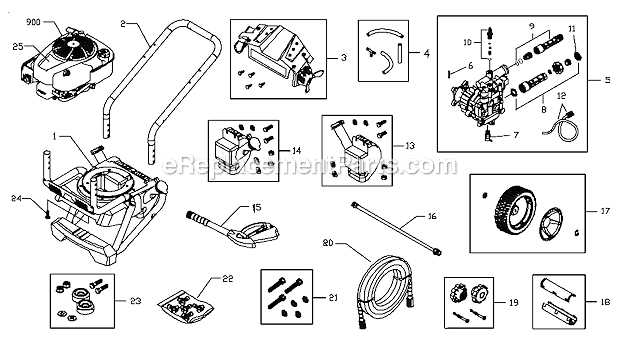

Knowing how to identify the different components of your cleaning machine is crucial for proper maintenance and troubleshooting. Understanding what each part looks like and how it fits into the overall system will make repairs more manageable and prevent unnecessary confusion. Every part has a unique function, and recognizing these will help you pinpoint any issues quickly.

Recognizing Key Components

The most important parts of the system include the motor, pump, hose, and nozzle. The motor is typically easy to identify as it is the largest component, often located at the rear of the unit. The pump is usually found near the motor and is responsible for moving the fluid through the system. The hose, often flexible and long, connects the machine to the nozzle, which directs the flow of water onto surfaces. Familiarizing yourself with these key elements allows for faster problem diagnosis.

Using Manuals and Resources

If you’re unsure about any component, the user manual and online resources are valuable tools. Many manufacturers provide detailed diagrams and labeling to help owners understand their equipment. These resources often include photos or drawings that show the precise location and appearance of each part, aiding in their identification and maintenance.

Common Issues with Cleaning Equipment Components

As with any mechanical device, various parts of your outdoor cleaning equipment may experience wear and tear over time. Recognizing the common issues that arise in specific components can help you address problems early and maintain the machine’s performance. Regular inspection and timely fixes are essential to avoid larger, more costly repairs.

Motor and Pump Failures

One of the most frequent issues encountered is motor or pump malfunction. The motor might fail to start or operate inefficiently due to a lack of maintenance, fuel issues, or electrical problems. Similarly, the pump may experience low output, reduced pressure, or even leaks if the internal seals become worn. Identifying these symptoms early can help prevent complete system failure and ensure smooth operation.

Clogged or Damaged Hoses and Nozzles

Another common issue is the clogging or damage of hoses and nozzles. Over time, debris or mineral buildup can obstruct the flow of water, reducing efficiency. A damaged hose or nozzle can also lead to leaks, causing water to spill out at unwanted locations. Regularly checking and cleaning these parts will ensure that water flows freely and at the desired pressure for optimal performance.