When it comes to maintaining any mechanical equipment, having a clear understanding of its internal elements is essential. Knowing how each piece functions and interacts ensures efficient use and easy troubleshooting. Whether you’re conducting routine maintenance or replacing worn-out pieces, having access to a visual guide makes the process smoother and more effective.

Familiarizing yourself with the specific layout of your machine helps avoid common errors and ensures proper reassembly after repairs. Each element plays a unique role, and knowing their precise location and function can save time and money. By carefully studying the parts map, users can quickly identify damaged sections and confidently select the appropriate replacement items.

In this guide, we’ll walk you through a detailed examination of the key components, providing helpful tips for using the visual references effectively. This knowledge will not only improve your repair skills but also extend the longevity of your equipment, ensuring it runs at optimal performance.

Overview of Stihl 250 Chainsaw Parts

Understanding the components of your tool is crucial for maintaining its performance and efficiency. Each element plays a significant role in ensuring smooth operation, from the engine to the smallest internal mechanisms. Knowing how these parts function together helps with effective maintenance and quick repairs, ensuring the equipment stays in top condition.

Here is a general breakdown of the main sections of your tool:

- Engine Components – The heart of your tool, responsible for generating power.

- Fuel System – Includes the tank, lines, and filter, providing the necessary fuel to the engine.

- Cutting Mechanism – The chain, bar, and sprocket work together to perform the cutting action.

- Air Intake System – Ensures the engine receives adequate airflow for combustion.

- Safety Features – Mechanisms like the brake and throttle control ensure safe operation during use.

Each of these sections has a specific function that, when maintained properly, contributes to the overall longevity and effectiveness of your tool. By regularly inspecting and understanding the components, you can detect any potential issues before they affect performance.

Identifying Key Components in the Diagram

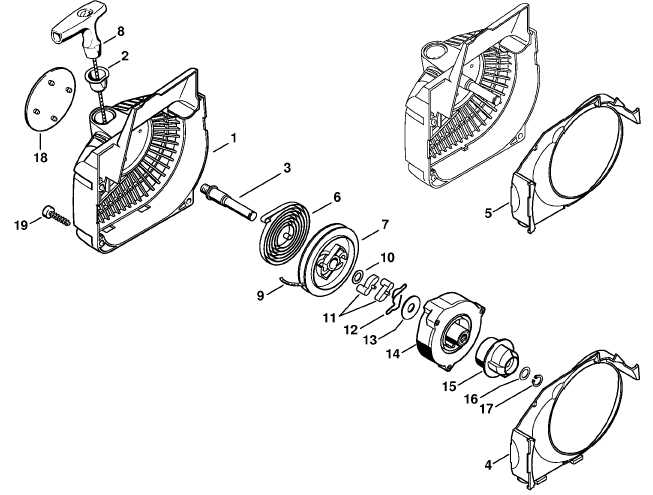

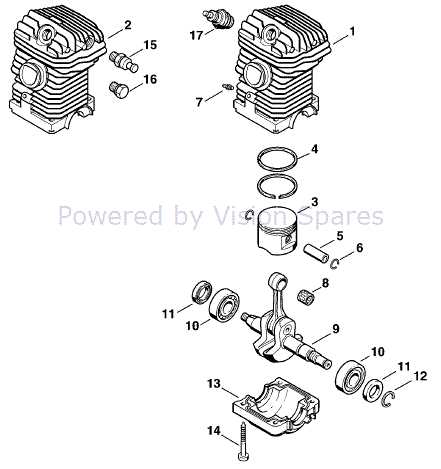

When studying the internal layout of your equipment, recognizing the major components is the first step in effective maintenance and repair. By pinpointing these essential elements, you gain a better understanding of how each part functions and interacts with the others. This knowledge empowers you to troubleshoot issues efficiently and ensure that everything is properly assembled.

Key components to focus on include:

- Engine assembly – The driving force behind your tool’s operation, including the ignition and piston systems.

- Fuel system – Fuel tank, lines, and filters that transport and manage fuel flow to the engine.

- Cutting mechanism – The bar and chain, responsible for performing the actual cutting motion.

- Throttle and safety controls – Features that regulate operation and ensure user safety during use.

- Cooling system – Components that keep the engine from overheating, ensuring smooth functioning.

By closely inspecting these areas in the reference guide, you’ll be able to identify any potential problems and address them before they escalate. This will not only extend the lifespan of your equipment but also improve its overall performance.

How to Use the Parts Diagram for Repairs

Using a visual reference guide is an essential tool when repairing mechanical equipment. It allows you to easily locate the damaged components and identify the correct replacements, streamlining the repair process. With the right approach, you can perform repairs with greater accuracy and confidence, minimizing the chances of errors.

To make the most of your reference guide, follow these steps:

- Identify the damaged component – Start by locating the malfunctioning part and matching it with the corresponding section in the diagram.

- Consult the part number – Each element is labeled with a unique identification number to help you find the exact replacement.

- Understand the assembly – Pay attention to how the components fit together and how removing one part might affect others.

- Double-check compatibility – Ensure the replacement parts are compatible with your model to avoid incorrect fits.

By following these steps, you can confidently replace damaged components and restore the proper functionality of your equipment. A visual guide simplifies the process, making repairs more efficient and reducing the risk of further complications.