Having a clear understanding of how each component of your recovery system functions is essential for effective maintenance and troubleshooting. Whether you’re a seasoned off-roader or a newcomer, knowing how to identify parts and recognize potential issues can make a significant difference in keeping your setup in optimal condition.

Disassembling and reassembling your device requires careful attention to detail. Understanding the structure of each element and how they interconnect allows for efficient repairs and replacements. By recognizing these crucial sections, you’ll be better equipped to perform maintenance tasks and solve common mechanical problems.

In this guide, we will explore the various components of the system, offering insight into common malfunctions and how to address them. Whether you’re dealing with wear and tear or looking to upgrade your setup, this information will serve as a valuable resource for keeping your equipment running smoothly.

Understanding the Badlands 12000 Winch Components

Every recovery system consists of several key elements that work in unison to perform its primary functions. Recognizing each component and understanding its role is crucial for efficient operation and troubleshooting. These individual sections vary in size and function, yet all contribute to the overall success of the mechanism.

For optimal performance, it’s important to identify the main features and their interactions. From the motor to the pulley system, each part must be properly maintained to avoid breakdowns. Understanding how each component operates can help you spot issues early and ensure a smooth recovery process when needed.

In this section, we will examine the core elements of the system, providing insights into their specific roles and how they contribute to the unit’s overall effectiveness. With this knowledge, you’ll be better equipped to perform repairs, maintenance, and upgrades when necessary.

How to Read a Winch Parts Diagram

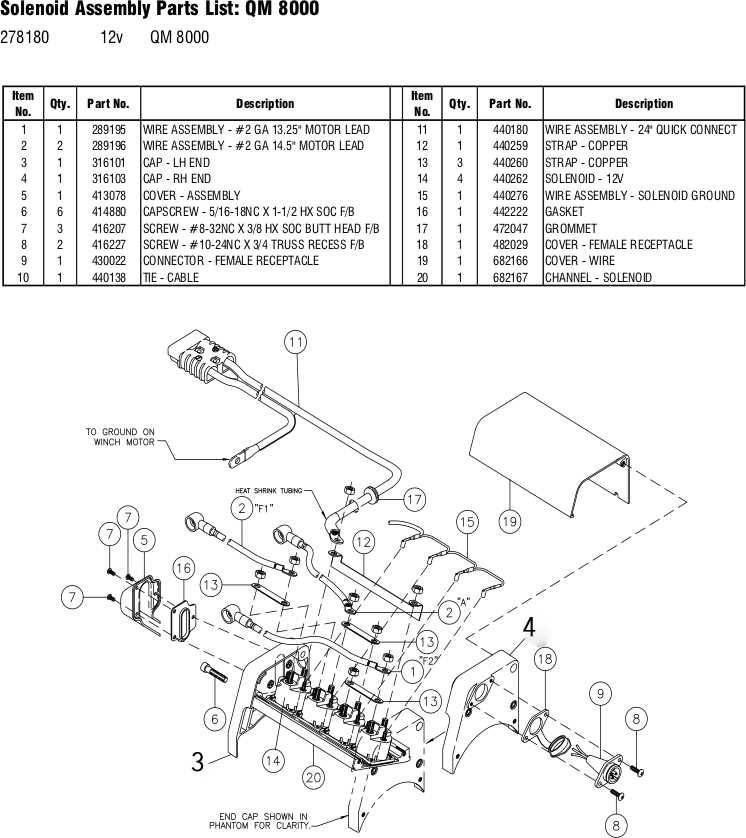

Understanding technical illustrations is essential for anyone looking to maintain or repair mechanical systems. These visuals break down complex machinery into easy-to-understand components, showing how everything fits together. By learning how to read these diagrams, you can identify which parts need attention and how to replace or adjust them properly.

Identifying Key Components

The first step in interpreting a technical drawing is identifying the main elements of the system. Each part is usually labeled, either by number or name, and these labels correspond to the list provided in the manual. Understanding what each part does and how it interacts with others will help you navigate the drawing more efficiently.

Understanding Part Relationships

Once you’ve identified the components, it’s important to understand how they are connected. Diagrams typically show the relative positioning of each part, with lines indicating how they interact or connect. Pay attention to these lines, as they can reveal important information about assembly, maintenance, and potential failure points.

Common Issues and Repair Tips for Badlands Winch

Even the most reliable recovery systems can encounter problems over time. Identifying and addressing common issues early can prevent larger failures and ensure the equipment functions effectively. From motor malfunctions to cable wear, being proactive about maintenance can save both time and money in the long run.

Electrical and Motor Problems

One of the most common issues in these systems is electrical failure. A malfunctioning motor can lead to sluggish performance or complete inoperability. Check for loose connections or damaged wiring that might interrupt the flow of electricity. If the motor is overheating, ensure it is not clogged with debris or exposed to excessive moisture, which can cause short circuits.

Cable Wear and Tear

Cables often experience wear due to friction and heavy use. Over time, they may become frayed or damaged, compromising their strength. Regularly inspect the cable for signs of damage and replace it if necessary. Properly storing the cable after each use and ensuring it is properly spooled can help prolong its lifespan and prevent kinks or tangles.