Maintaining and repairing outdoor machinery can be a complex task, especially when you are unfamiliar with its components. Having a clear visual representation of the different parts and their arrangement can simplify troubleshooting and repairs. Knowing the layout of each element is crucial for both novice and experienced users to ensure proper function and longevity of the equipment.

Identifying individual components in a machine allows for quicker maintenance procedures and helps in pinpointing areas that may need attention. Whether you’re replacing a part or conducting regular inspections, understanding the overall assembly is essential for effective care. Having a detailed reference is a valuable tool for keeping the system running smoothly.

Every piece plays a role in ensuring your machine operates as intended, and recognizing how they fit together can prevent costly mistakes and delays. This guide will walk you through the key components, helping you manage and maintain your equipment with ease.

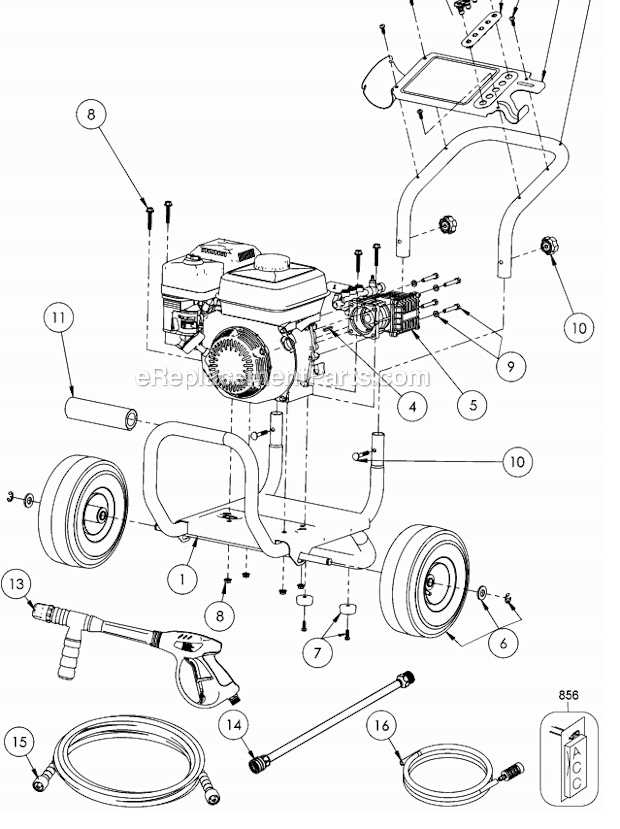

Understanding the Dxpw3425e Parts Layout

When it comes to machinery, understanding how the various elements are arranged is essential for effective operation and repair. Each component within the system works together to achieve optimal performance, and a clear view of their positions helps users identify any potential issues quickly. Knowing where every part fits into the overall structure can save time and effort when diagnosing or maintaining the machine.

The layout is a map of how different sections connect and interact with each other. By becoming familiar with this configuration, users can more easily spot wear, misalignments, or damage. This knowledge makes it easier to perform routine maintenance tasks, as well as replace specific components when needed. Additionally, it helps ensure that repairs are done correctly, preserving the efficiency of the entire system.

Whether you’re handling the equipment for the first time or have extensive experience, a clear understanding of its internal structure is invaluable. Being able to visually identify each piece’s role allows for better decision-making, faster troubleshooting, and more efficient repairs. The clearer the layout, the easier it is to maintain and extend the lifespan of the machinery.

How to Read the Dxpw3425e Diagram

Reading a schematic of machinery requires an understanding of how each component is visually represented and how to interpret the connections between them. These layouts are designed to simplify the identification of different sections and their functions, enabling users to follow the structure easily. By familiarizing yourself with common symbols, labels, and arrangement patterns, you can gain a clearer view of the system’s design and make the maintenance process smoother.

Key Features of the Layout

- Symbols and Labels: Each part is typically marked with a label or symbol that identifies its function. Recognizing these symbols is crucial for understanding how to navigate the layout.

- Connections: The lines or arrows between components represent how parts interact with each other. Pay attention to how these connections flow, as they reflect the order and process of the machine’s operation.

- Numbering: Often, parts are numbered sequentially or by groups. This numbering system allows you to quickly locate each item in the layout and reference it during repairs or adjustments.

Interpreting the Information

- Step-by-Step Approach: Start by identifying the main components and their connections. Focus on one section at a time to avoid confusion.

- Understand the Flow: Many diagrams show the flow of energy or materials. Following this flow can help you understand how the system functions as a whole.

- Cross-Referencing: Use the provided labels to cross-reference parts with real-life components for a more accurate understanding.

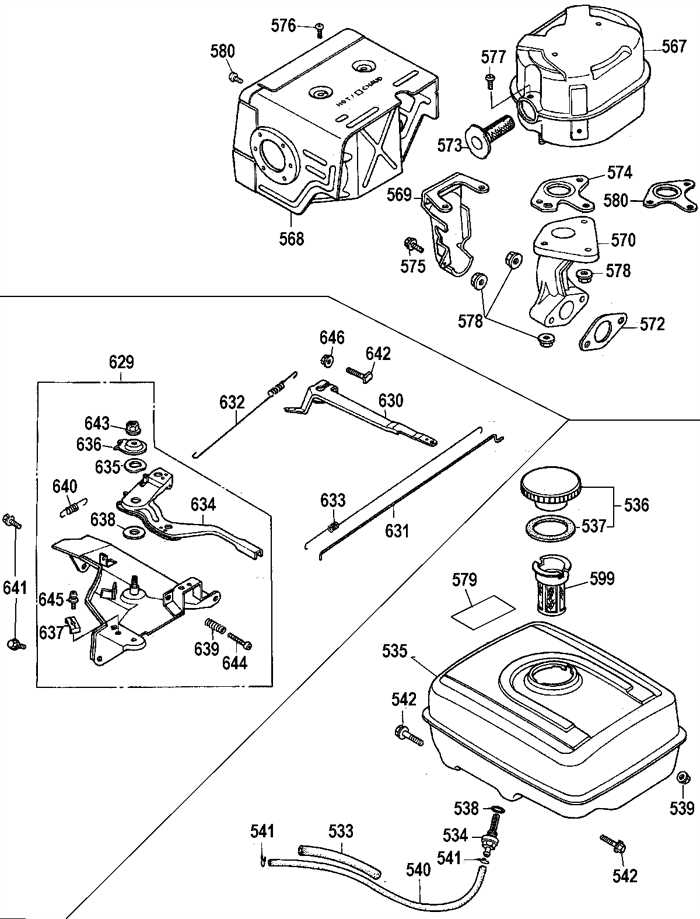

Key Components of the Dxpw3425e Model

Every machine is made up of essential elements that allow it to function efficiently. These components are designed to work together, each fulfilling a specific role that contributes to the overall performance. Understanding the main parts that make up the system is crucial for both maintenance and troubleshooting, as it helps identify potential issues and ensures that each element is in good working order.

The core of the equipment includes mechanical and electrical components that operate in harmony to complete various tasks. Some of these elements are responsible for power transmission, while others regulate flow, movement, or provide stability. Knowing how these components interact allows users to diagnose problems more effectively and maintain the system with greater ease.

Familiarizing yourself with the key components ensures a better understanding of how the system operates as a whole. By recognizing each element’s purpose, users can make informed decisions when replacing or servicing specific components. This knowledge helps maintain the longevity and efficiency of the machine, ultimately leading to a smoother and more effective operation.