Understanding the intricate structure of your equipment is essential for proper upkeep and efficient operation. This section focuses on how to identify and manage various elements within the system, ensuring smooth functionality over time.

Familiarizing yourself with the layout of key components can help simplify maintenance tasks, reduce the likelihood of malfunctions, and extend the lifespan of the machine. Having a clear understanding of how parts fit together plays a crucial role in troubleshooting and repairs.

Whether you’re performing routine checks or addressing specific issues, being able to navigate through the various elements effectively will save time and prevent costly mistakes.

Understanding the Equipment Components

When it comes to maintaining complex machinery, understanding the individual components that make up the system is essential for ensuring longevity and efficiency. Each element plays a unique role, and knowing how they interconnect allows for easier troubleshooting and repair.

Key System Elements

The core parts of the machine are designed to work together, and knowing their function can significantly improve your maintenance efforts. Here are some of the critical components to consider:

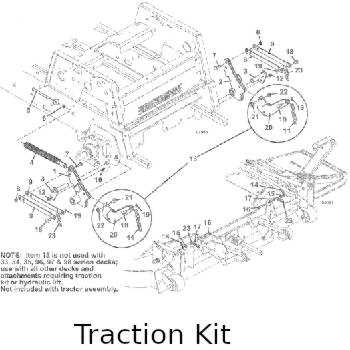

- Engine and drive system: Power and movement are generated here.

- Transmission: Manages the flow of power throughout the machine.

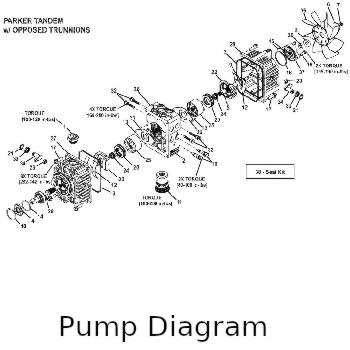

- Hydraulic system: Controls various functions that require fluid movement.

- Wheels and tracks: Allow for mobility across different surfaces.

- Control system: Manages the operator’s input and controls the equipment’s behavior.

Interpreting Component Connections

Recognizing how each part interacts with others is just as important as understanding their individual functions. Proper alignment and maintenance of these connections can prevent system failures and enhance performance. Regular inspections and knowledge of each connection’s role help maintain smooth operation over time.

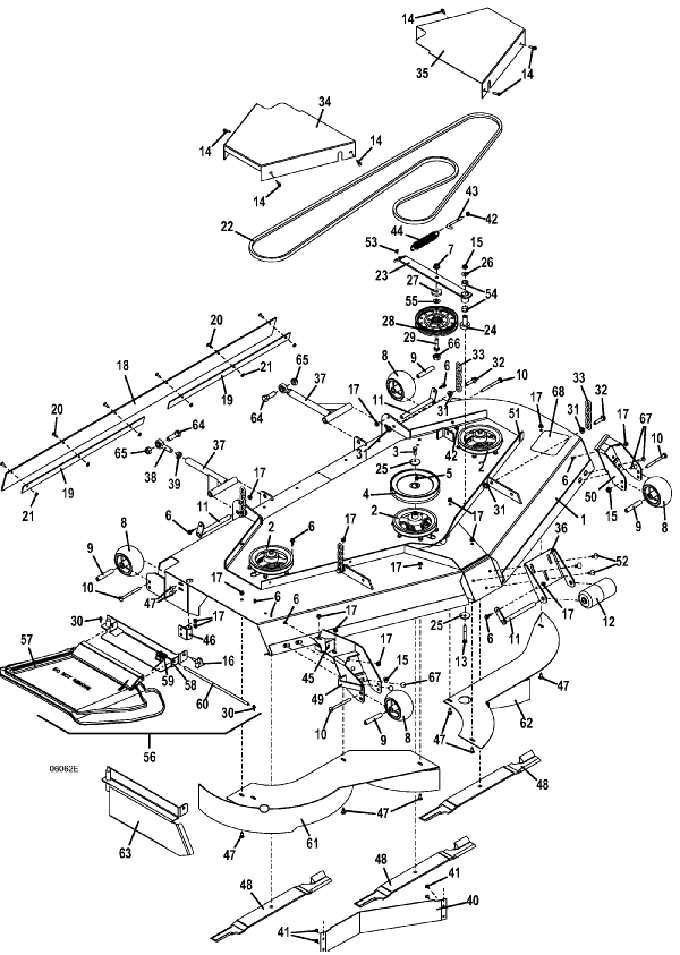

How to Read the Assembly Layout

Understanding how to interpret the visual representation of your equipment’s components is crucial for effective maintenance. The layout offers a comprehensive view of how each part fits together and how to identify specific elements for repair or replacement.

To begin, focus on the main sections of the layout, which are typically divided into clusters representing various machine functions. These clusters are marked with numbers or labels, allowing you to easily locate the corresponding part in the inventory.

Additionally, pay attention to the connecting lines or arrows, which show how each component is linked. These connections are important for understanding how a failure in one part might affect others, ensuring you address issues effectively.

Common Maintenance Tips for Your Equipment

Regular upkeep is essential to keep your machine running smoothly and to prevent unexpected breakdowns. By following a few simple maintenance practices, you can ensure the longevity of your equipment and avoid costly repairs.

Routine Inspections

Conducting regular checks is one of the most effective ways to prevent issues. Look for any signs of wear or damage, particularly on moving parts. Ensuring everything is securely connected and in proper alignment can save you from future disruptions.

- Inspect hydraulic systems for leaks or low fluid levels.

- Check belts and pulleys for signs of wear.

- Ensure all electrical connections are intact.

Lubrication and Fluid Changes

Proper lubrication is vital to minimize friction and prevent excessive wear on critical components. Additionally, changing fluids at recommended intervals helps maintain smooth operation and protects the internal systems from damage.

- Lubricate moving parts such as joints and pivots regularly.

- Replace hydraulic and engine oils based on the manufacturer’s guidelines.

- Check air filters and replace when necessary to ensure optimal engine performance.