When it comes to maintaining and repairing machinery, a clear understanding of its individual components is crucial. Knowing how different parts interact with each other allows for more efficient troubleshooting and proper upkeep. This section provides an overview of the essential components and assembly structure of such equipment, helping users to familiarize themselves with its inner workings.

By exploring the specific elements that make up the machine, you can enhance your ability to perform necessary repairs or adjustments. Whether you are a professional technician or a DIY enthusiast, being able to identify and replace worn-out parts ensures your equipment operates at its best for longer periods.

Understanding the assembly process will help users identify areas that may require attention and guide them in selecting the correct components for replacements or upgrades. By mastering the component layout, users gain confidence in both routine maintenance and unexpected repairs.

Understanding Key Components of Your Equipment

Proper knowledge of an equipment’s structure is essential for effective maintenance and troubleshooting. Every tool is made up of various elements that serve specific functions, and understanding these components can greatly improve the longevity and efficiency of the machine. By familiarizing yourself with how the individual parts come together, you’ll be able to address issues and perform repairs with greater ease.

Essential Elements for Proper Functionality

Each component plays a vital role in ensuring smooth operation. Some parts are responsible for power generation, while others manage airflow or control mechanisms. Recognizing the role of each piece helps in identifying potential weaknesses or areas that may require attention over time. Routine inspection and understanding the specific function of each part contribute to keeping the equipment in optimal condition.

Identifying and Replacing Worn Components

Over time, certain parts may become worn out due to regular use. Knowing how to identify these worn-out components and replace them promptly can prevent further damage and costly repairs. Whether it’s a belt, filter, or housing, being familiar with the overall design allows users to perform maintenance tasks with precision, ensuring reliable performance throughout the tool’s lifespan.

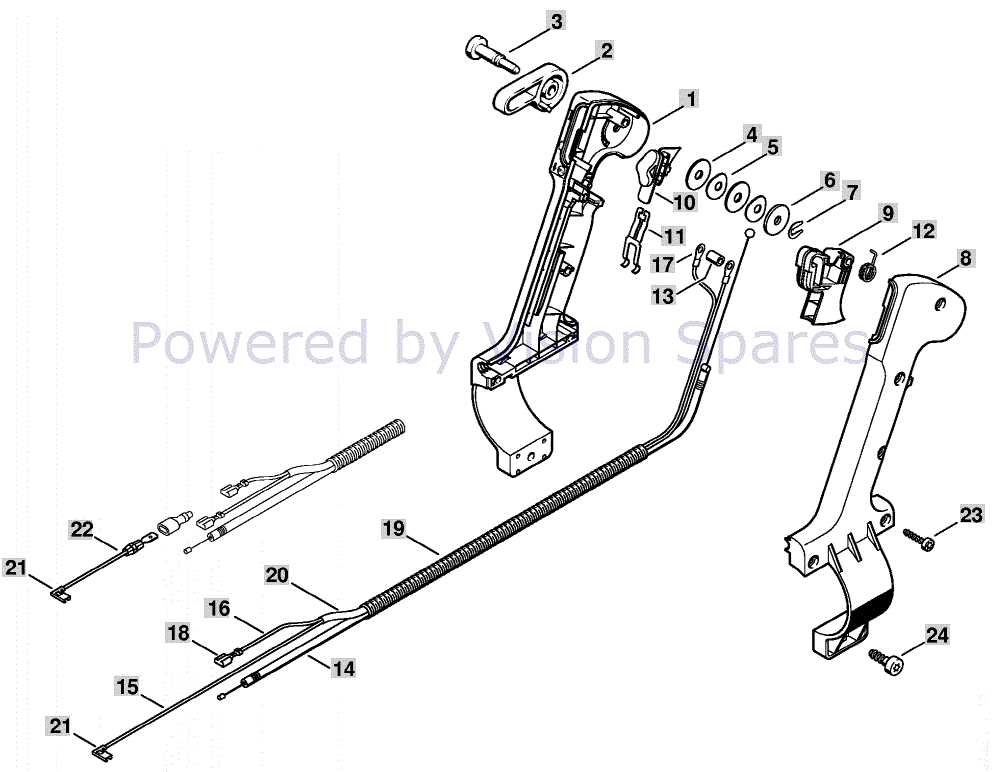

How to Read a Machine Assembly Illustration

Interpreting a detailed assembly illustration is essential for anyone working on equipment maintenance or repair. These visuals provide a breakdown of the different elements and how they fit together within the system. Understanding the representation allows users to identify each component’s position, functionality, and relationship with other parts, making repairs and assembly much more manageable.

Breaking Down the Visual Layout

The illustration typically follows a logical structure, where the parts are arranged in a way that mimics their physical layout. By examining the diagram closely, users can match the visual depiction with the actual components in front of them. Components may be numbered or labeled, providing a direct link between the visual and the physical parts, allowing for easier identification during maintenance tasks.

Locating and Identifying Key Elements

One of the first steps in understanding such an illustration is to identify the key parts that play crucial roles in the machinery’s functionality. Some illustrations include a reference key that highlights specific components, while others rely on color coding or numbering for easy reference. Familiarizing yourself with the symbols and their meanings will ensure that the diagram is not only read but also used effectively in repairs or assembly processes.

Essential Elements for Equipment Maintenance

To keep machinery functioning properly, it is important to focus on the essential components that require regular upkeep. These critical parts ensure that the equipment runs smoothly and efficiently. Regular inspection and timely replacement of worn-out components can prevent malfunctions and extend the lifespan of the machine. Knowing which elements need attention allows for a more proactive approach to maintenance.

Critical Components for Performance

Several key components are responsible for maintaining optimal performance. Elements like filters, belts, and fuel lines play a significant role in ensuring that the equipment runs smoothly. Regularly checking these parts for wear and replacing them when necessary will help prevent potential issues during operation. A strong focus on maintaining these parts will keep the machinery operating at its best for a longer time.

Timing and Tools for Replacements

Understanding when to replace specific parts is crucial. For example, components such as air filters and spark plugs need to be checked periodically and replaced after a certain amount of usage. Knowing how to perform these replacements using the right tools ensures that repairs are done correctly. With the proper timing and tools, maintaining these essential elements becomes a straightforward task that helps keep your equipment in top shape.