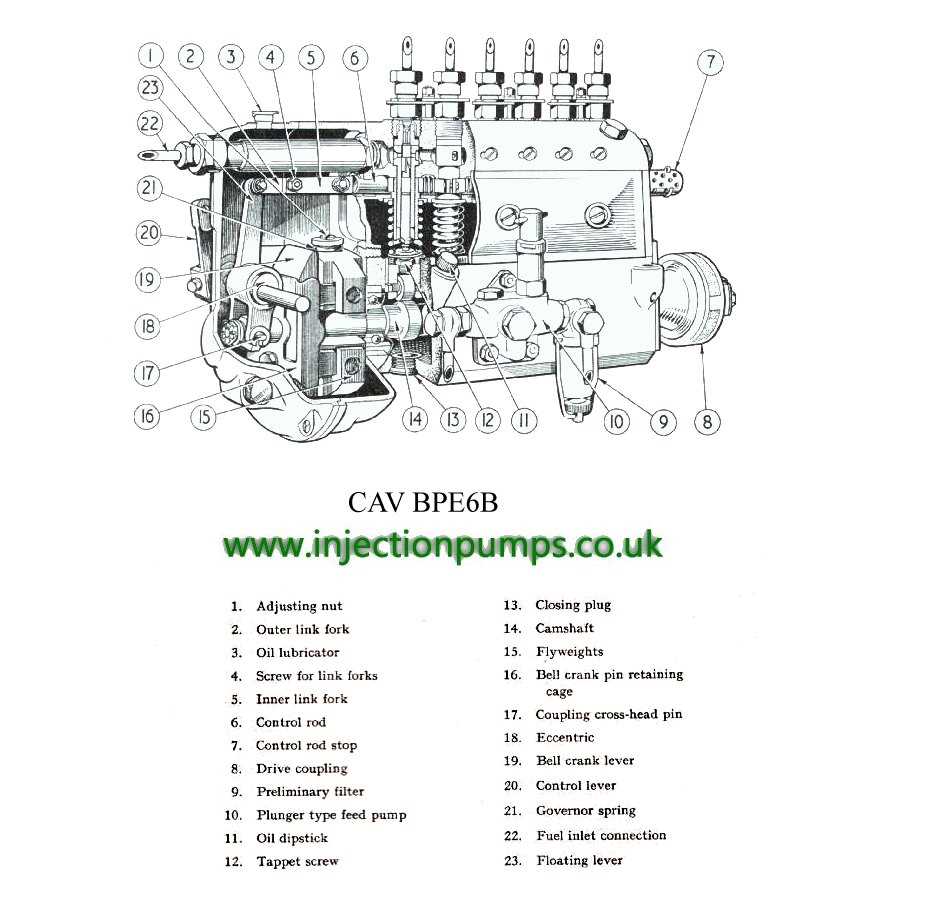

The operation of a diesel engine relies heavily on precise fuel delivery mechanisms. To ensure optimal performance, it is essential to understand the key elements that contribute to the system’s functionality. These components work together seamlessly to regulate fuel flow and pressure, ensuring efficient combustion.

Accurate knowledge of each element is crucial for diagnosing issues and performing maintenance. Recognizing how each piece interacts with the others helps technicians identify potential problems and address them before they impact engine performance. Whether for repair or routine upkeep, familiarity with the system’s layout is invaluable.

By exploring the intricate design of these crucial engine parts, we gain insight into their specific roles and how they contribute to overall efficiency. Understanding this system also enables better decision-making when it comes to repairs and part replacements, ultimately prolonging the life of the engine.

Understanding Zexel Injection Pump Components

The fuel delivery system plays a critical role in engine efficiency. It consists of various components that control the flow, pressure, and timing of the fuel reaching the combustion chamber. These elements must work together flawlessly to ensure the engine runs smoothly, with each part contributing to the overall performance and reliability.

Each component has a unique function, from controlling the fuel supply to adjusting the timing of its release. Understanding the role of each element helps technicians diagnose issues and perform accurate repairs. Maintenance becomes easier when the connection between the different components is clear, ensuring that all parts function harmoniously.

Proper knowledge of these system components helps not only with troubleshooting but also with optimizing performance. By ensuring that all parts are in good working order and correctly calibrated, it is possible to extend the lifespan of the engine while maintaining fuel efficiency and reducing emissions.

How Zexel Injection Pump Works

The fuel delivery system is designed to regulate the amount of fuel that enters the engine, ensuring the correct mixture for efficient combustion. The process involves a series of steps, from drawing in fuel to injecting it at precisely the right moment. The key is maintaining the right pressure and timing, which is critical for performance and emissions control.

Fuel Intake and Pressure Regulation

First, fuel is drawn into the system from the tank. The fuel is then pressurized by a mechanical device to ensure it can be injected effectively into the combustion chamber. This pressure must be maintained at a specific level to prevent incomplete combustion or engine stalling.

Precise Timing and Delivery

Once the fuel is pressurized, the system releases it into the engine at just the right time during the combustion cycle. This timing is crucial as it ensures the fuel is atomized correctly for optimal combustion. Any delay or premature injection can result in inefficient burning and power loss.

Common Issues with Zexel Pumps

Fuel delivery systems can experience a range of problems that impact their performance and the overall efficiency of the engine. These issues often stem from wear, improper maintenance, or contamination, which can lead to irregular fuel flow, pressure issues, or even complete system failure. Identifying and addressing these problems early can prevent more serious damage and costly repairs.

Fuel Flow and Pressure Problems

One of the most common issues is improper fuel flow, which can result from clogged filters, faulty seals, or damage to the fuel lines. When the system cannot maintain the correct pressure, the engine may experience rough idling, stalling, or a loss of power. It is essential to regularly inspect and clean the system to avoid these complications.

Timing and Delivery Failures

Incorrect timing of fuel delivery can cause inefficient combustion, leading to poor engine performance. This can happen due to worn-out components or misalignment in the system. Regular calibration and maintenance are necessary to ensure that all components work in sync, delivering fuel at the optimal moment for combustion.