In every complex system, a clear understanding of its components and how they work together is essential for efficient operation. The mechanisms that drive fluid circulation and control within a system rely on various interconnected elements, each serving a unique role. Familiarity with these components can significantly enhance troubleshooting, maintenance, and performance optimization.

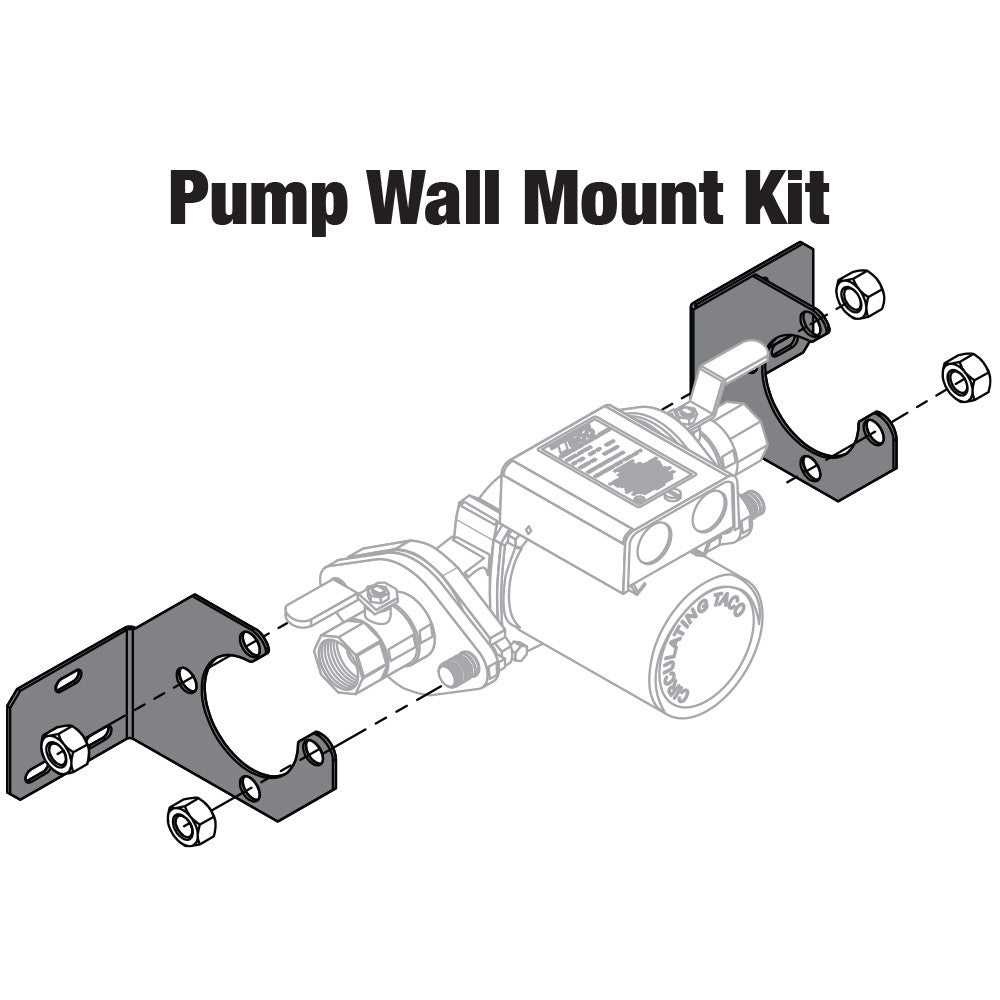

Exploring the structure and layout of these components helps in visualizing how each piece contributes to the overall system. From electrical connections to mechanical units, knowing where each part fits and how it interacts with others can prevent potential malfunctions and extend the lifespan of the equipment.

Maintenance and repair often become easier when you have a clear understanding of the component arrangement. Whether you’re looking to replace a worn-out part or enhance the system’s efficiency, this knowledge serves as a solid foundation for any technical work you may need to perform.

Understanding Taco Pump Components

To fully grasp the functionality of any fluid circulation system, it’s crucial to have a clear understanding of the different elements involved. These components work in harmony to ensure the system operates smoothly, efficiently, and reliably. Each piece plays a distinct role, from directing the flow of liquids to maintaining the pressure levels required for optimal performance.

The Essential Elements of the System

The primary elements of this kind of system typically include mechanical, electrical, and control components. Mechanical elements, such as rotors or impellers, facilitate fluid movement, while electrical components provide power and control over operation. Control systems regulate the flow, pressure, and sometimes temperature, ensuring everything operates within safe and efficient parameters.

How Components Interact for Optimal Function

When all components are correctly integrated, the system becomes capable of delivering consistent and reliable service. The efficiency of one element often depends on the proper functioning of others. For example, an imbalance or malfunction in one component can lead to pressure fluctuations or even system failure, which is why understanding their roles and interconnections is vital for effective operation and maintenance.

Common Issues with Taco Pump Parts

In any complex system, issues can arise over time, often due to wear and tear or improper maintenance. Recognizing common problems early can prevent serious damage and costly repairs. From mechanical failures to electrical malfunctions, understanding typical issues can help in diagnosing and addressing them quickly.

Mechanical Failures

Wear on moving components is one of the most frequent causes of malfunction. Over time, elements such as rotors or seals can degrade, leading to reduced efficiency or complete failure. This can result in insufficient fluid flow, causing the system to operate below optimal levels.

Electrical and Control Malfunctions

Electrical issues, such as faulty wiring or sensor malfunctions, can also affect system performance. If the control system isn’t working properly, it can lead to improper flow regulation, causing pressure imbalances or overheating. Regular inspections of the electrical components are essential for preventing these types of failures.

How to Maintain Taco Pump Parts

Proper maintenance is essential for the longevity and efficiency of any mechanical system. Regular care helps prevent common issues, improves performance, and extends the life of critical components. By following a routine maintenance schedule and addressing potential problems early, you can avoid costly repairs and system downtime.

Regular Inspections

One of the most important aspects of upkeep is conducting routine inspections. This involves checking for any signs of wear, leaks, or unusual vibrations. Pay particular attention to components that are subjected to high wear and tear, such as seals, rotors, and electrical connections. Identifying issues early allows for prompt repairs, preventing further damage.

Cleaning and Lubrication

Cleaning and lubrication are vital for keeping moving parts functioning smoothly. Over time, dust and debris can accumulate, causing friction and reducing efficiency. Regularly cleaning the system and applying the appropriate lubricant to moving components helps maintain optimal performance. Be sure to follow manufacturer recommendations for the type of lubricant and cleaning methods to avoid damaging delicate parts.