When using any mechanical equipment, having a clear understanding of its individual components is essential for smooth functioning and long-term durability. Identifying each part and knowing how they work together can help in efficient operation and troubleshooting issues. This knowledge is particularly useful for ensuring that every element is in optimal condition and functioning as intended.

In this section, we will explore the various elements that make up these machines, highlighting their specific roles. We will also explain how to use visual resources to easily identify and understand each component, allowing you to take better care of the equipment and perform any necessary repairs or maintenance with confidence.

Understanding Stihl Pressure Washer Components

Every machine is made up of several critical elements that work together to ensure smooth operation. Understanding these key components can greatly enhance the maintenance and longevity of the equipment. When each part is in good working condition, the entire system performs optimally, allowing you to get the most out of your investment.

Main Functional Parts

The primary elements in any machine include the engine, the water intake, and the power mechanism. Each part plays a unique role in converting energy into a functional output. The engine serves as the driving force, while the intake ensures a steady supply of water. Together, these components deliver consistent performance when used properly.

Supportive and Auxiliary Components

Beyond the primary elements, there are also supportive mechanisms such as the hose, nozzle, and connectors. These parts are essential for directing the output and controlling the flow. Although they may seem less complex, they are vital for directing and regulating the energy created by the main engine. Ensuring they are free from damage or wear is crucial for maintaining the machine’s effectiveness.

Identifying Key Parts for Maintenance

Regular upkeep of any equipment requires the ability to identify which components need attention and when. Understanding how different parts interact and where potential issues may arise can help in preventing downtime and costly repairs. By focusing on the most critical areas, you can ensure the equipment remains in good working condition for longer periods.

Common Areas to Inspect

The most important areas to examine regularly include the engine, connectors, and water delivery system. These elements are subject to wear and tear due to constant operation, and even minor damage can result in poor performance. Checking for leaks, loose connections, or build-up is essential to maintaining efficiency.

Tools and Techniques for Inspection

Using the right tools can make a significant difference when inspecting for potential issues. A simple visual inspection, combined with pressure tests and cleaning techniques, can reveal any hidden faults. Regularly cleaning the water intake, as well as checking the hose and nozzle for blockages, ensures smooth operation and prevents performance degradation.

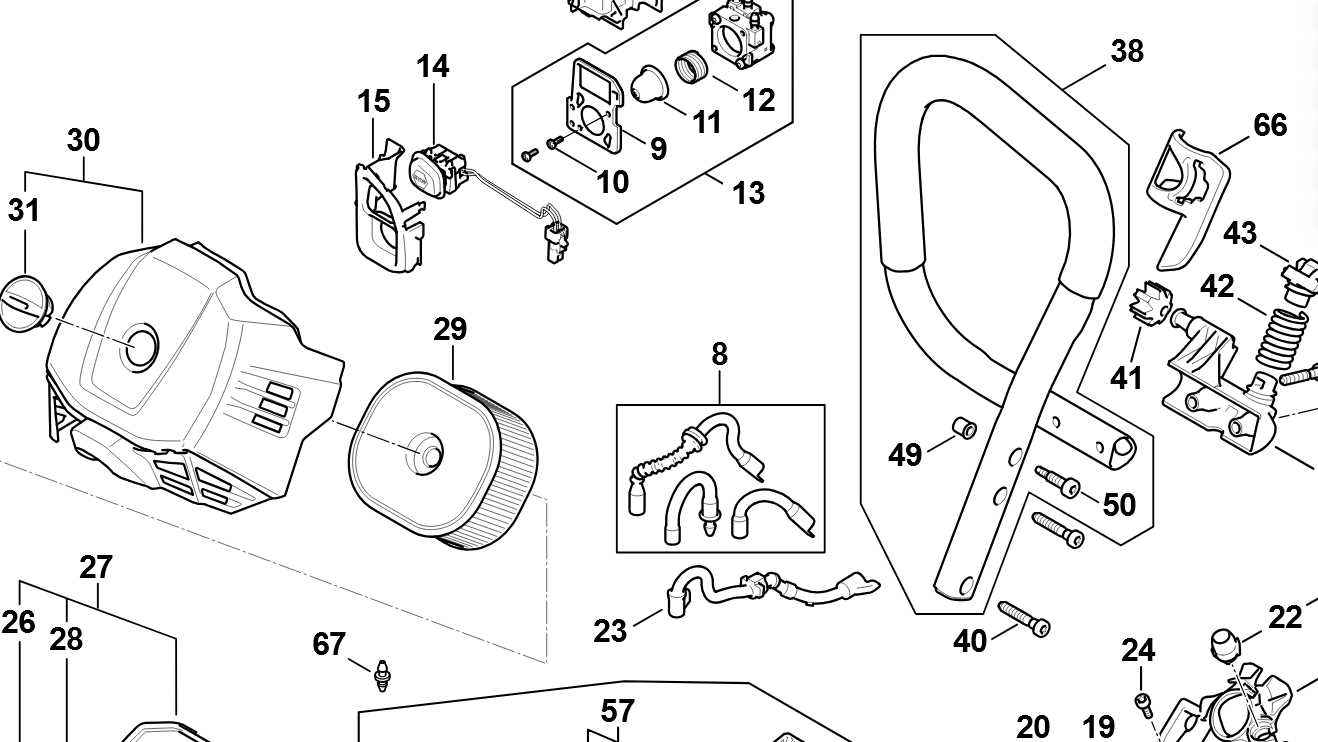

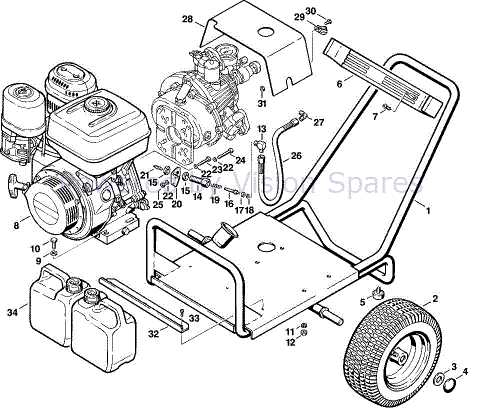

How to Use the Parts Diagram Effectively

Understanding how to read and utilize visual guides is essential for maintaining and repairing machinery. These resources allow you to quickly identify individual components and their connections, making it easier to troubleshoot issues or replace faulty elements. Knowing how to navigate these illustrations can save time and effort when performing repairs or routine maintenance.

Start by familiarizing yourself with the layout of the diagram. Often, components are organized into sections, showing both their position and relationships with other elements. This will help you pinpoint the specific part that needs attention. Pay close attention to labels, as they typically provide important information about part numbers, sizes, and functions.

Additionally, combining the visual guide with a manual or online resources can further enhance your understanding. These resources often include detailed descriptions of each part’s function and common problems, helping you make informed decisions when performing maintenance tasks.