Knowing the essential components of your garden tool and how they function is crucial for effective maintenance and repairs. Whether you’re troubleshooting an issue or performing routine upkeep, identifying each element’s role can help ensure long-lasting performance. Understanding the structure of these devices also allows for smoother replacement of worn-out components.

Proper knowledge of the internal system is key to efficient care. Without this understanding, even basic repairs can become challenging. By familiarizing yourself with the different segments, you can enhance your skillset and avoid unnecessary confusion when parts need replacing or adjustment. This knowledge is not just for repair experts but for anyone who wants to maintain their equipment in optimal condition.

Learning to identify and manage the various sections of the tool will give you the confidence to handle maintenance tasks independently. With the right guidance, fixing common issues becomes a straightforward process. Having access to detailed visuals of the components further simplifies the entire procedure, offering a clearer view of each section’s placement and connection.

Understanding the Remington Pole Saw Parts

When it comes to managing your equipment, knowledge of its key components is essential for effective operation and maintenance. Identifying each element and understanding its function will help you prevent malfunctions and ensure longevity. With this awareness, basic repairs and replacements become more manageable, making your tool more reliable for future use.

The Core Components

The primary sections of the tool include the motor, blade assembly, and handle. Each piece plays a vital role in ensuring the smooth operation of the entire unit. Motor functionality is the driving force behind movement, while the blade mechanism is responsible for the cutting action. Understanding these core elements can simplify troubleshooting when problems arise.

Maintenance and Troubleshooting

Regular upkeep is key to preventing breakdowns. Familiarizing yourself with the different components helps identify when a particular part may be worn out or malfunctioning. With this knowledge, repairs can be executed more efficiently, preventing unnecessary costs and extending the lifespan of the tool. Be sure to inspect every element periodically for signs of wear and tear.

How to Read a Pole Saw Diagram

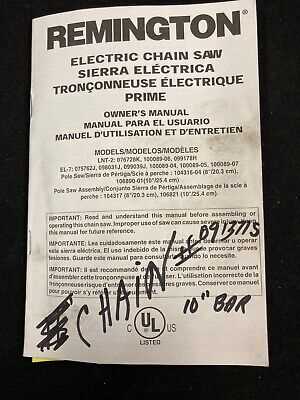

Interpreting visual guides for your equipment can seem complex, but understanding how to read them is an essential skill for effective maintenance. These guides typically display an overview of the device’s components and their specific placement, helping you identify each section and its relationship to the others. With practice, you’ll be able to quickly locate any part and determine if it requires attention.

Start by familiarizing yourself with the key symbols and labels used in these illustrations. Each part is often represented with clear markings or numbers, allowing you to match them with corresponding sections in the user manual or online resources. Understanding the layout and flow of the visual representation will enable you to diagnose problems and carry out repairs with greater confidence.

Common Remington Pole Saw Repair Parts

Maintaining garden tools often involves replacing certain sections that can wear out over time. Whether due to regular use or damage, understanding which parts typically need replacement can save both time and money. Knowing which components are more prone to failure allows for quicker repairs and ensures the tool remains functional for future tasks.

Motor and Drive Components

The motor and drive mechanisms are essential for the operation of any garden tool. Over time, wear can affect the motor’s efficiency or cause it to malfunction. Replacing worn-out gears, belts, or other internal mechanisms can restore the device to full working order. Regular inspection of these components can prevent larger issues and avoid costly repairs.

Cutting Mechanisms and Accessories

Components related to the cutting function, such as the blade or chain, often experience the most wear. These parts can become dull, damaged, or misaligned, leading to poor performance. Replacing or sharpening these elements as needed will help maintain effective operation and ensure clean cuts with every use.