When maintaining and repairing a smoker, understanding its internal structure is essential. Each element plays a critical role in ensuring optimal performance. Knowing how to identify and replace malfunctioning components can extend the lifespan of your grill and enhance its efficiency. Proper identification of the various parts will help prevent errors during troubleshooting and repairs.

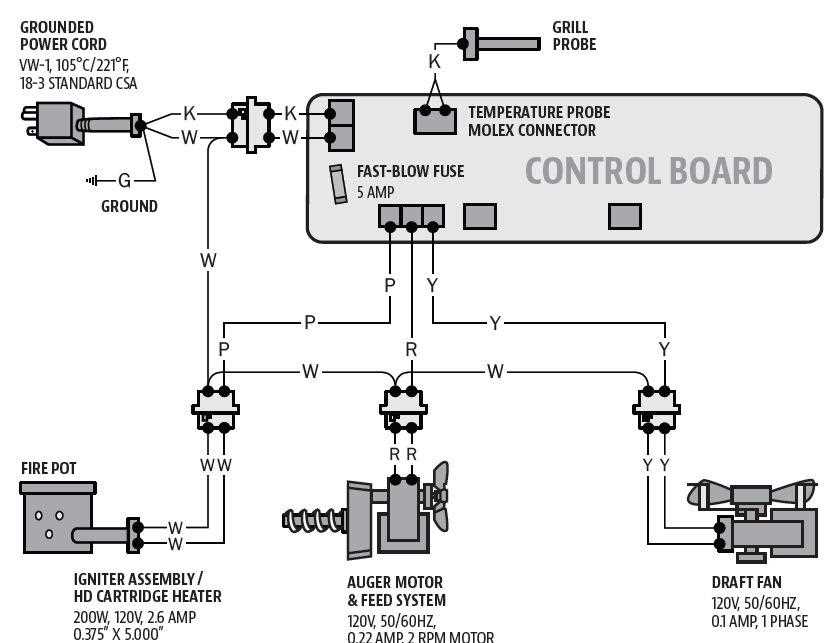

Detailed illustrations are often provided to simplify the process of recognizing the individual pieces. These visuals help users quickly locate specific components, ensuring that replacements and adjustments are done correctly. Whether you’re dealing with issues related to temperature regulation, fuel distribution, or structural concerns, knowing the layout of these internal mechanisms is key.

Step-by-step instructions based on these clear representations can guide even novice users through repairs, ensuring that the right parts are chosen and replaced. This knowledge is indispensable for those who wish to keep their smokers in peak working condition without unnecessary costs from professional repairs.

Understanding Pit Boss 820 Components

To maintain and repair your smoker efficiently, it’s crucial to understand the role of each internal element. Every component has a specific function, and recognizing their layout can make repairs and replacements much easier. From fuel management to heat control, the smoker’s internal system relies on these parts working in harmony to achieve optimal performance.

Key Functional Elements

Various mechanisms in the grill ensure that cooking conditions are consistent and reliable. Elements such as the fuel hopper, heat distribution system, and temperature sensors play pivotal roles in the overall efficiency of the smoker. Understanding how these components interact will help identify where issues might arise and ensure smoother repairs when necessary.

Common Troubleshooting Areas

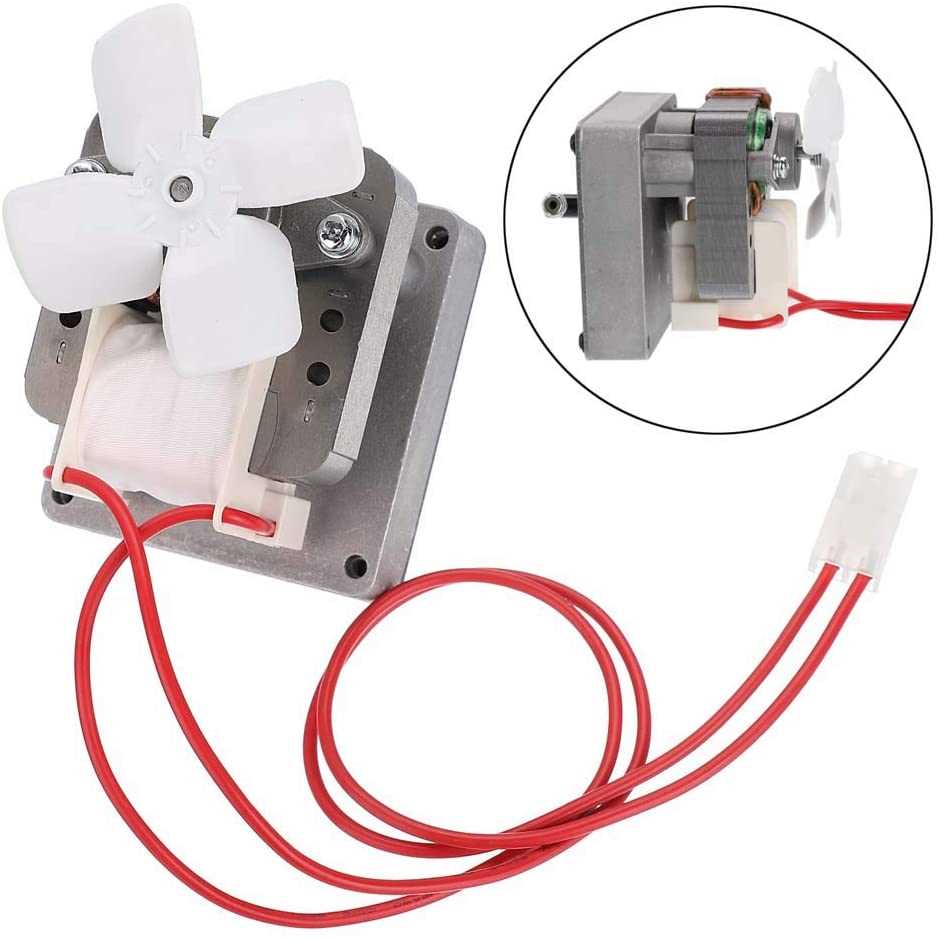

Many users face challenges with specific parts, such as the auger or fan system, which can affect performance. Recognizing how these components are connected within the structure is the first step in diagnosing problems. If you understand the overall design and how each piece functions, pinpointing malfunctioning areas becomes a straightforward process.

How to Identify Parts on the Diagram

Identifying each component of your smoker becomes significantly easier with a detailed visual reference. By analyzing a well-structured layout, you can quickly locate specific sections and understand their placement within the overall system. This is especially helpful when diagnosing issues or planning replacements.

Steps to Identify Components

To effectively identify components, follow these simple steps:

- Study the overall structure: Begin by understanding the general layout of the smoker and how the elements are arranged.

- Locate key sections: Focus on areas such as the fuel system, heat control, and air circulation mechanisms.

- Match numbers or labels: Most illustrations include numbered or labeled references to help identify individual parts.

Common Identifiers

Many diagrams use unique identifiers such as numbers, letters, or shapes to mark components. Knowing what each symbol represents is essential for recognizing the part you need to address. Some common identifiers include:

- Temperature control units: Often marked with a temperature icon or numerical range.

- Fuel system components: Usually labeled with words such as “hopper” or “auger” to distinguish them from other sections.

- Electrical parts: May be marked with electrical symbols or wire connections.

Replacing Parts on Your Smoker

Replacing components on your smoker is a necessary task to keep it running efficiently. Over time, parts may wear out or malfunction, leading to reduced performance. Knowing when and how to replace specific elements is crucial for maintaining the overall function of the grill and avoiding costly repairs or replacements.

When replacing parts, it’s important to carefully follow the manufacturer’s instructions to ensure proper installation. Each component plays a role in the overall system, and using the correct replacements will help maintain optimal functionality. Always make sure to purchase quality parts that match your smoker’s model for the best results.

Before starting the replacement process, turn off and disconnect all power sources to prevent accidents. Be sure to remove any fuel or debris that could obstruct your work area. Once the smoker is safe to work on, carefully remove the faulty component and install the new one, ensuring a secure fit to maintain the smoker’s performance.

Step-by-Step Guide for Component Swap

When it’s time to replace a faulty component, following a clear, organized process ensures the task is completed correctly. A well-executed replacement extends the life of your smoker and keeps it functioning at its best. This step-by-step guide will walk you through the necessary actions to swap out a malfunctioning element safely and effectively.

Step 1: Prepare the Smoker

Before beginning any repair work, make sure the smoker is completely turned off and unplugged from any power sources. Disconnect any fuel or electrical connections to avoid any accidents. Clean the work area and remove any debris that could interfere with the process.

Step 2: Remove the Faulty Component

Identify the malfunctioning part and gently remove it from its position. Depending on the component, you may need specific tools such as a screwdriver or wrench. Handle the part carefully to avoid damaging surrounding components.

Step 3: Install the New Component

Once the faulty part is removed, place the new component in its proper position. Make sure the part aligns correctly with the smoker’s structure. Secure it tightly, ensuring a firm fit, and check if any wires or connections need to be reattached.

Step 4: Test the New Component

After installation, power the smoker back on and test the functionality of the new part. Check that everything is working as expected, including temperature regulation, fuel flow, or air circulation. If necessary, make minor adjustments to ensure everything runs smoothly.

Common Smoker Repair Issues

Like any piece of equipment, your smoker may encounter various issues over time. Understanding the most common problems helps you identify them early and take steps toward quick resolution. Familiarity with these common issues ensures that you can maintain your smoker in optimal working condition, reducing downtime and enhancing performance.

Temperature Control Problems

One of the most frequent issues users face is difficulty maintaining the right cooking temperature. This can result from a malfunctioning temperature sensor, a clogged vent, or issues with the heat distribution system. Identifying the root cause and addressing it quickly ensures that your smoker performs at its best, preventing overcooked or undercooked food.

Fuel and Airflow Issues

Another common issue is improper fuel distribution or airflow. If the fuel isn’t being delivered correctly or the airflow is restricted, it can affect cooking efficiency and performance. Cleaning the fuel system and inspecting air pathways are key steps in resolving this problem and restoring proper operation.