When it comes to maintaining outdoor machinery, understanding the internal structure and components is essential for efficient operation and longevity. A clear understanding of each individual element allows for easier troubleshooting, repairs, and overall performance improvements.

By breaking down the layout of your equipment and identifying the role of each piece, you can perform maintenance tasks with greater confidence and precision. Whether you are fixing a malfunction or simply ensuring that everything is running smoothly, knowledge of your machine’s key elements is crucial.

In this guide, we will walk you through the essential components that make up your gardening equipment, providing insights into their functions and offering helpful tips for replacing or maintaining them. With the right tools and a detailed understanding of how everything fits together, you’ll be ready to keep your equipment in top working condition.

Understanding Garden Machine Component Layout

To operate and maintain garden machinery effectively, it’s crucial to understand how each component is positioned and how they interact with each other. A clear visual map of the machine’s structure helps identify which parts are vital for its performance and how they contribute to its overall operation.

Every piece within the mechanism has a specific function, whether it’s to provide power, facilitate movement, or ensure smooth operation. Recognizing these roles makes it easier to troubleshoot, replace damaged parts, and keep the machine running optimally over time.

Key Elements of the Machinery Structure

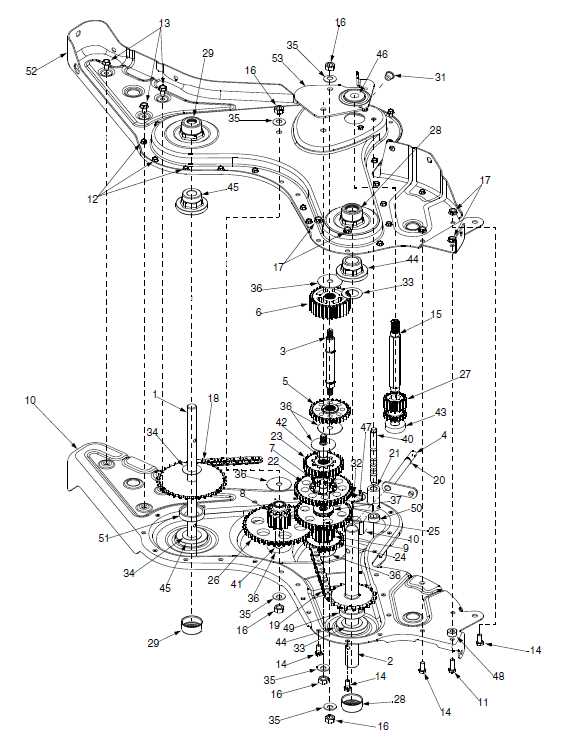

The framework consists of several essential components, such as the engine, drive system, and transmission. Each of these parts works together to deliver the necessary force for the machine to operate effectively. Understanding where they are located and how they are connected is the first step in proper maintenance.

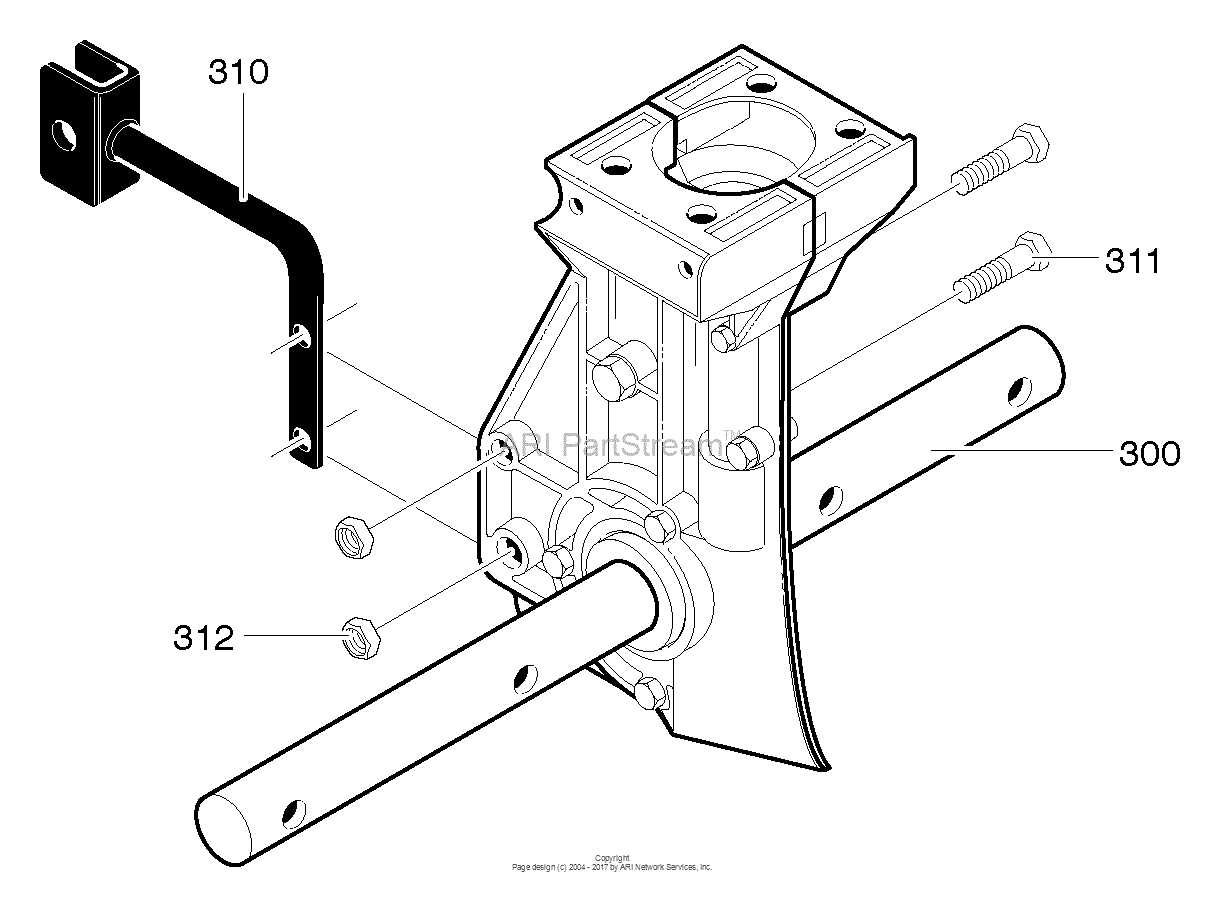

Visual Layout for Easy Maintenance

Having a visual representation of the machinery’s configuration is helpful when performing any repair or maintenance tasks. This layout allows users to quickly identify the components they need to focus on, ensuring that time is spent efficiently and issues are resolved swiftly.

Common Parts and Their Functions

Every piece of garden equipment consists of several crucial elements, each playing a specific role in its overall performance. Understanding these components and how they function together ensures that the machine operates efficiently and lasts longer. Recognizing the purpose of each part helps with both troubleshooting and preventative maintenance.

Among the most important components are the engine, which provides the necessary power, and the transmission system, responsible for transferring that power to the moving parts. Additionally, the control handles allow for easy manipulation, while the blades or rotating elements perform the heavy work. These components must be in good condition to ensure optimal functionality and reliability.

Maintaining the proper function of these common elements reduces the likelihood of wear and tear, saving time and money on repairs. Regular inspection and timely replacement of worn-out components will keep your machinery working efficiently for years to come.

Step-by-Step Guide to Equipment Maintenance

Proper maintenance is essential to keep your garden machinery running smoothly and extend its lifespan. Following a step-by-step approach ensures that each aspect of the equipment is inspected and maintained thoroughly. Regular care will also prevent costly repairs by addressing potential issues early.

Initial Inspection and Cleaning

Start by inspecting the machine for any visible damage or wear. Clean the exterior to remove dirt and debris that may have accumulated during use. Pay close attention to the moving parts, as these are more susceptible to dirt buildup, which can affect performance. Ensure that all air filters are free from blockages to maintain engine efficiency.

Checking and Replacing Key Components

Next, inspect essential components such as the drive system and blades for any signs of damage. Tighten any loose screws or fasteners, and replace any worn or damaged parts. Regularly checking these critical elements will help prevent more significant problems down the road and ensure the machine operates at peak performance.

How to Identify and Replace Components

Identifying and replacing worn or damaged components is an essential part of maintaining your garden machinery. Properly diagnosing issues ensures that you address the root cause of problems rather than just symptoms. Knowing when and how to replace parts can prevent more extensive damage and improve the machine’s overall performance.

Steps to Identify Damaged Components

Start by inspecting the equipment for any obvious signs of wear. Look for unusual sounds, vibrations, or performance issues that could indicate faulty components. Here’s how to begin:

- Check the engine for irregularities like excessive smoke or unusual noise.

- Examine the moving parts for wear, cracks, or other visible damage.

- Look for signs of leaks or broken seals in the transmission system.

- Inspect the control handles for smooth operation and ensure they are properly aligned.

Replacing Worn or Broken Components

Once you’ve identified the damaged components, follow these steps to replace them:

- Shut off the engine and disconnect any power sources to avoid accidents.

- Use the appropriate tools to remove the damaged part carefully.

- Match the new component with the original to ensure compatibility.

- Install the new part and secure it properly with the correct fasteners.

- Test the equipment to ensure the new part works as expected.

Regularly replacing damaged parts will help keep your machinery running efficiently and prevent breakdowns during use.

Tips for Efficient Equipment Repairs

Performing repairs quickly and effectively is essential for minimizing downtime and keeping your garden machinery in top condition. Having a strategy in place, along with the right tools and knowledge, can help you avoid unnecessary complications and ensure that each repair is done right the first time. Efficiency in repairs not only saves time but also extends the life of your equipment.

Preparation and Organization

Before starting any repair work, make sure you have all necessary tools and replacement components at hand. Organizing your workspace and ensuring that everything is within reach will streamline the process and reduce interruptions. It’s also important to carefully review the equipment’s manual and any available diagrams to familiarize yourself with the components you’ll be working with.

Test and Double-Check

After completing a repair, always test the machine to ensure everything is functioning as expected. Pay attention to any unusual sounds or behaviors that may indicate that something was missed or improperly installed. Double-check that all fasteners are tight, and the components are properly aligned to avoid future issues.

By staying organized and following a methodical approach, you can carry out repairs efficiently, preventing common mistakes and reducing the need for frequent fixes.