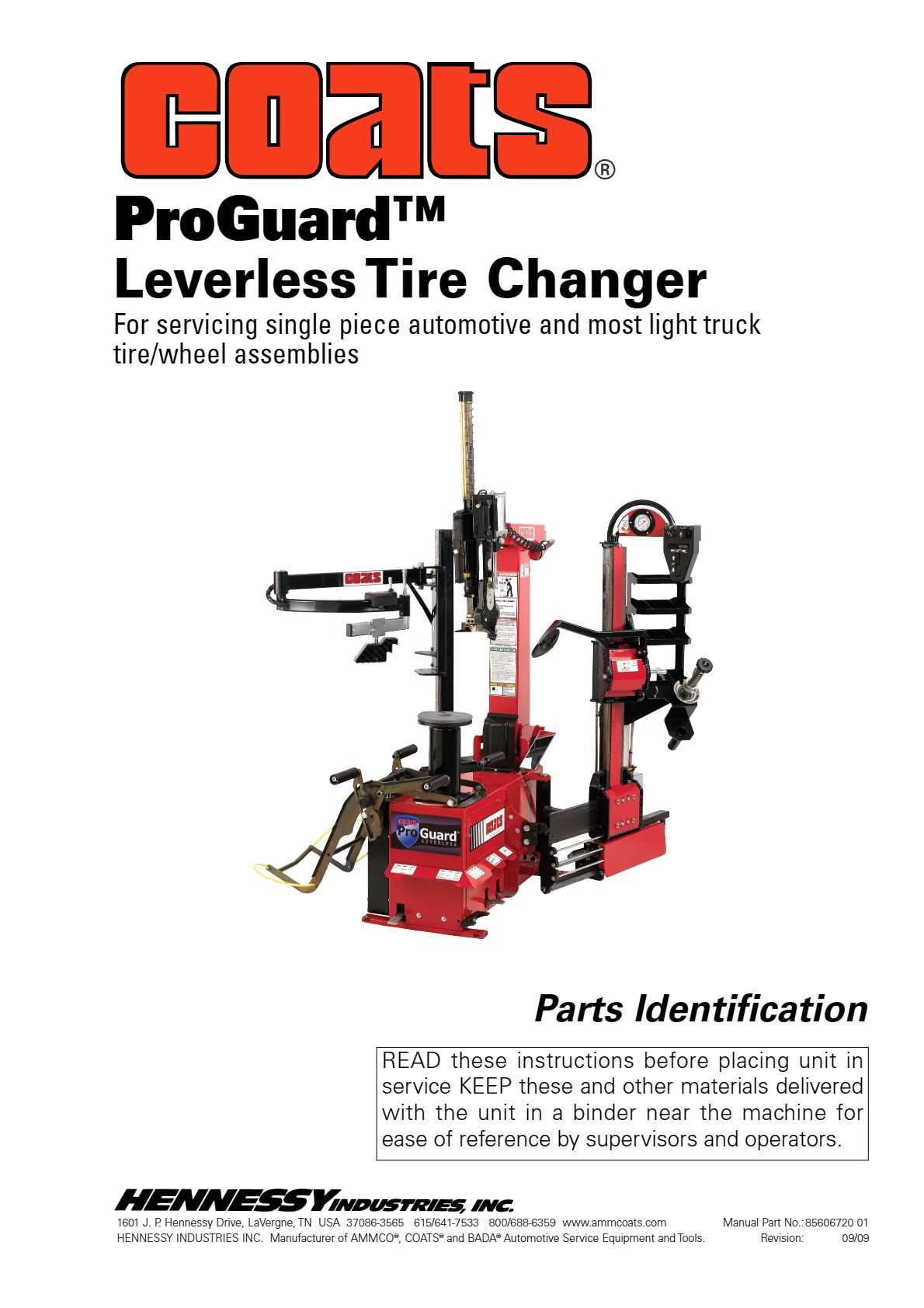

When working with complex machinery, having a clear representation of its internal structure is essential. Visual guides offer a detailed overview of the components, allowing technicians and engineers to quickly identify and understand how each part fits together. These resources are invaluable for troubleshooting, repairs, and maintenance tasks.

In this section, we will explore how such resources can aid in gaining a deeper understanding of a machine’s mechanical design. By breaking down the key elements, users can enhance their ability to perform necessary tasks efficiently and accurately.

Familiarity with these illustrations is crucial for anyone working with equipment that requires precise assembly or disassembly. With the right knowledge, even complex issues can be resolved more easily, saving both time and effort. Properly interpreting these diagrams is a valuable skill that can lead to smoother operations and longer-lasting machines.

Understanding the Coats 70x-ah-3 Diagram

Detailed illustrations of machine assemblies provide a visual representation of how the components work together. These images are essential for anyone involved in maintenance or repair, offering insight into the mechanical relationships between different parts. Having access to such resources can simplify complex tasks by breaking down the machine into its individual units.

How to Interpret the Layout

Each section of the layout represents a unique part of the machine’s structure, and understanding how to read it is key to effective troubleshooting. The arrangement of these elements is designed to reflect their real-world positioning, which helps technicians identify where a malfunction may occur. Familiarity with these representations allows for quicker diagnoses and more precise repairs.

Importance of Accurate Assembly

When assembling or disassembling machinery, following the correct order and ensuring that each part is properly connected is critical. An accurate map of the machine’s components minimizes errors and ensures everything is in its correct place. Properly interpreting these visuals is not only a time-saver but also a way to enhance the durability and performance of the equipment.

Key Components in Coats 70x-ah-3

Understanding the key elements of a machine is essential for effective maintenance and repair. Each component plays a vital role in the overall function, and recognizing these parts ensures that any issues can be pinpointed and addressed quickly. A machine is often made up of a variety of interconnected units, each contributing to its efficiency and performance.

Some of the primary elements include the motor, drive systems, control units, and safety mechanisms. Each of these components needs to work seamlessly together to ensure the machine operates correctly. Familiarizing oneself with these critical pieces allows technicians to perform accurate troubleshooting and ensure proper functioning during regular use.

In addition to the core mechanical elements, attention to detail in understanding auxiliary parts is also important. These smaller but essential units support the larger components, keeping the machine running smoothly. A thorough understanding of both the major and minor components aids in optimizing machine performance and longevity.

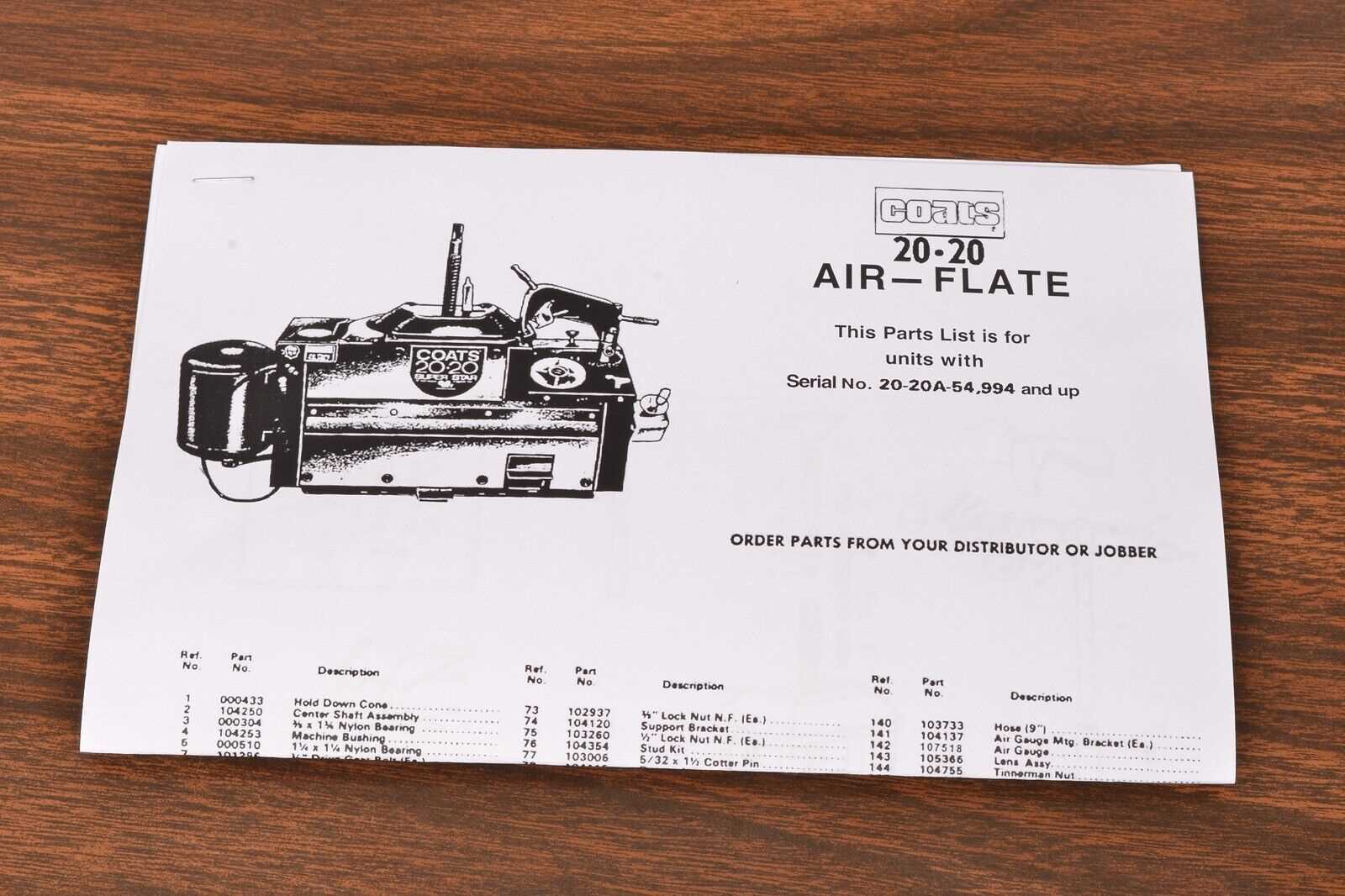

How to Read the Parts Diagram

Understanding a machine’s layout can be challenging, but with the right approach, interpreting it becomes straightforward. These illustrations are organized to visually depict how various elements fit together. By familiarizing yourself with the structure, you can quickly identify parts, their connections, and their roles in the overall system.

Key Steps in Interpretation

Reading such visual representations requires a methodical approach. Follow these steps to gain a deeper understanding:

- Identify the main sections: Begin by looking at the larger, more prominent components in the illustration. These usually represent the most critical parts of the machine.

- Examine the connections: Focus on how components are linked, either through physical connections or operational relationships. This will help you understand how each part functions in tandem.

- Look for labels: Many diagrams have labeled sections that clarify the function and name of each unit, making it easier to locate specific components.

- Understand the flow: Some illustrations include arrows or directional indicators that show the movement of materials, energy, or parts within the system. Follow these cues to better grasp the machine’s operation.

Tips for Better Understanding

To make reading these illustrations even easier, consider the following tips:

- Familiarize yourself with standard symbols: Many diagrams use universal icons or shapes to represent common parts, such as motors or switches.

- Review the manual: Cross-referencing the diagram with the accompanying manual can help clarify any uncertainties and provide additional context.

- Practice: The more often you read these layouts, the easier it will become to quickly identify and understand the components.