Farm machinery is built from a variety of complex components that work together to achieve optimal performance. Each piece plays a crucial role, contributing to the overall efficiency of the machine. Knowing how these elements interact and their individual functions is essential for proper maintenance and operation.

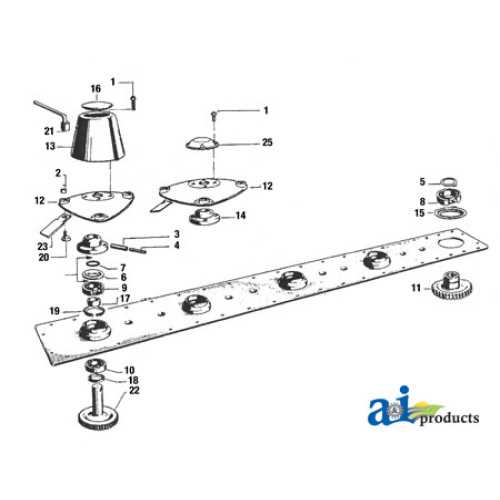

Identifying key elements within the machinery provides operators with a better understanding of how to maintain and troubleshoot effectively. A clear representation of these parts ensures that users can quickly locate and address issues, reducing downtime and improving productivity.

The layout and design of the machine are carefully structured to support its heavy-duty tasks. Understanding the positioning of each component allows for smoother operation and faster repairs. Whether it’s about the drive mechanism, the cutting elements, or the support systems, each section has its unique role that should be understood thoroughly.

Key Components and Their Functions

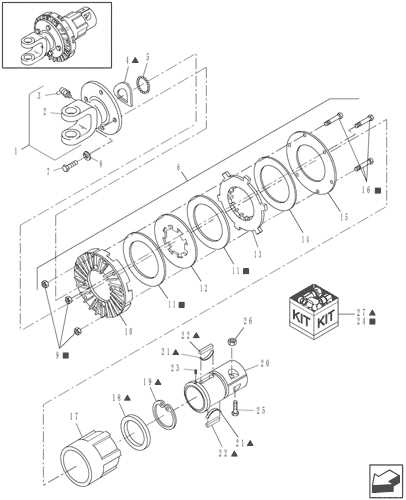

Each piece of agricultural machinery consists of essential components that work in tandem to ensure smooth operation. Understanding the role of each element is vital for efficient performance and longevity. These key elements are designed to support various tasks, from cutting to transportation, all while maintaining durability under heavy use.

The cutting mechanism is one of the primary features, responsible for delivering precise and consistent results. The blades and drive system work together to efficiently trim and separate materials. The efficiency of this system directly impacts the overall productivity of the machine.

Another critical part is the support structure, which stabilizes the entire assembly and ensures safety during operation. This structure helps absorb shock and maintain balance, preventing wear on other components. In addition, hydraulic systems play an essential role in powering several functions, such as adjusting blade height or operating the lifting mechanism.

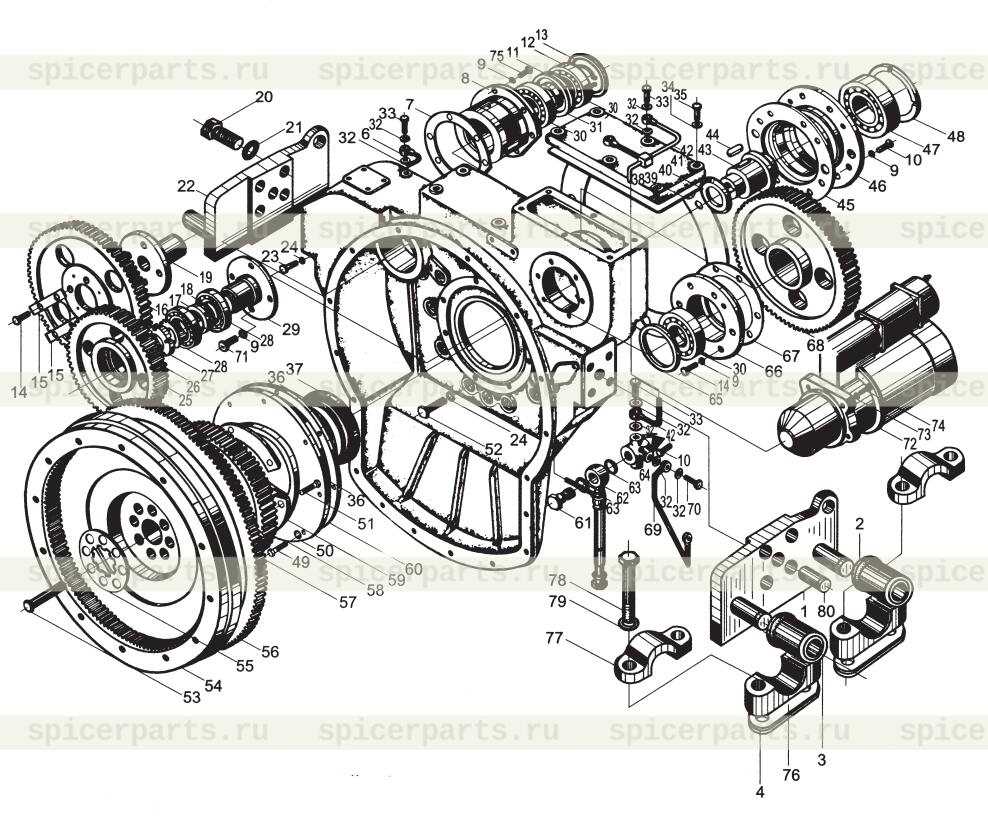

Lastly, the transmission system is responsible for transferring power between the engine and moving parts. This component must function without error to maintain the correct speed and force, ensuring that the machinery performs as expected even in demanding conditions.

Understanding the Parts Layout

Efficient operation of machinery heavily relies on how each individual element is arranged and interacts with others. The layout of the various components determines how well the machine performs and how easily it can be maintained. A clear understanding of this arrangement is crucial for operators to identify potential issues and ensure optimal functionality.

Component Placement and Functionality

The placement of each part is designed to maximize efficiency and safety. Key elements such as the cutting and drive systems are carefully positioned to work in harmony, minimizing friction and wear. Proper alignment also ensures that power is effectively transferred throughout the system, optimizing overall performance.

Accessibility and Maintenance Considerations

The arrangement of components not only influences performance but also impacts the ease of maintenance. Strategically placed access points allow for quick repairs or adjustments, reducing downtime. Clear layout planning ensures that routine inspections and component replacements can be performed with minimal disruption to daily operations.