Understanding the structure of complex equipment is crucial for effective maintenance and repair. Identifying individual elements and knowing their function helps ensure smooth operation and longevity. A well-organized overview simplifies the troubleshooting process, making it easier to pinpoint issues.

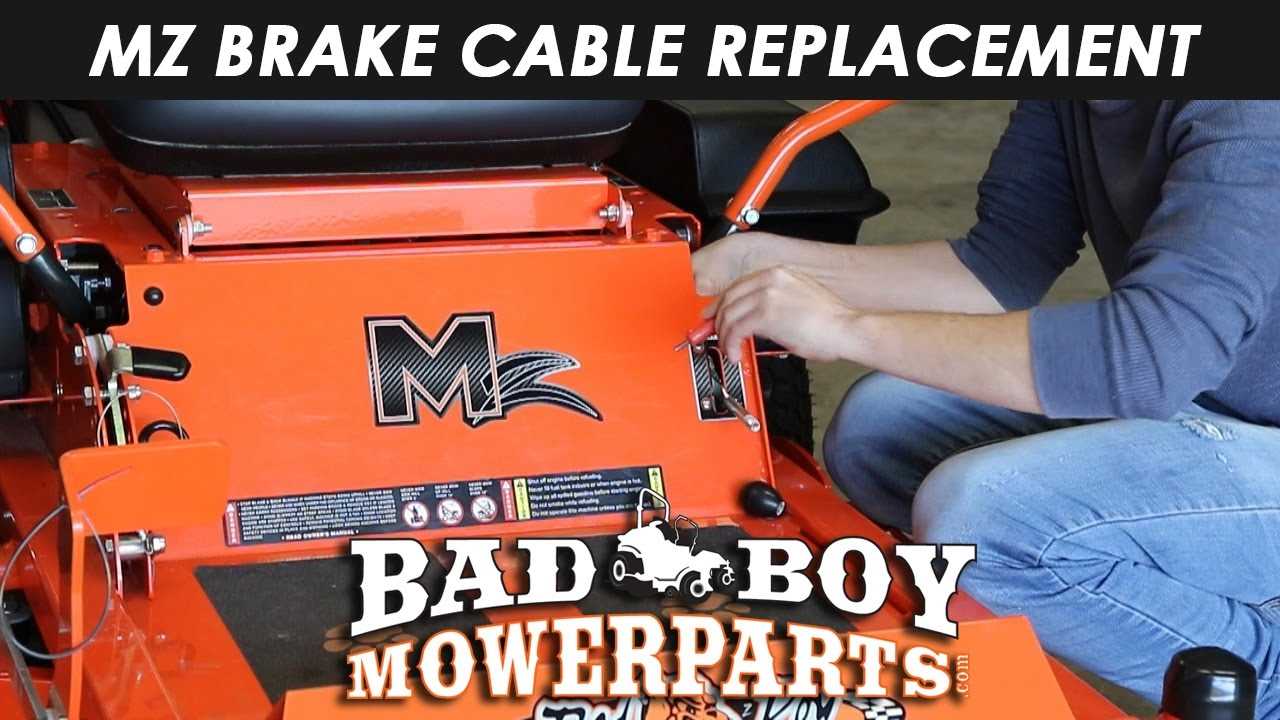

In this guide, we will walk through the essential elements of a specific model, providing insight into its configuration and how each part interacts within the system. Knowing how to locate and assess these components can save time and reduce errors during repair tasks.

Effective maintenance is often linked to having a clear visual representation of the system. The ability to reference a detailed map of the parts enhances the accuracy of any repair work and helps in making informed decisions regarding replacements or adjustments.

By exploring each element carefully, you will gain a deeper understanding of its role in the overall functionality, ensuring that future maintenance or upgrades can be performed with confidence and precision.

Understanding Bmz54kt740 Parts Layout

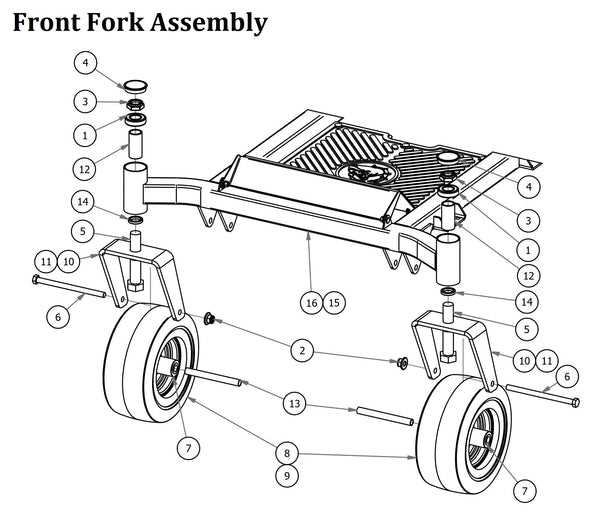

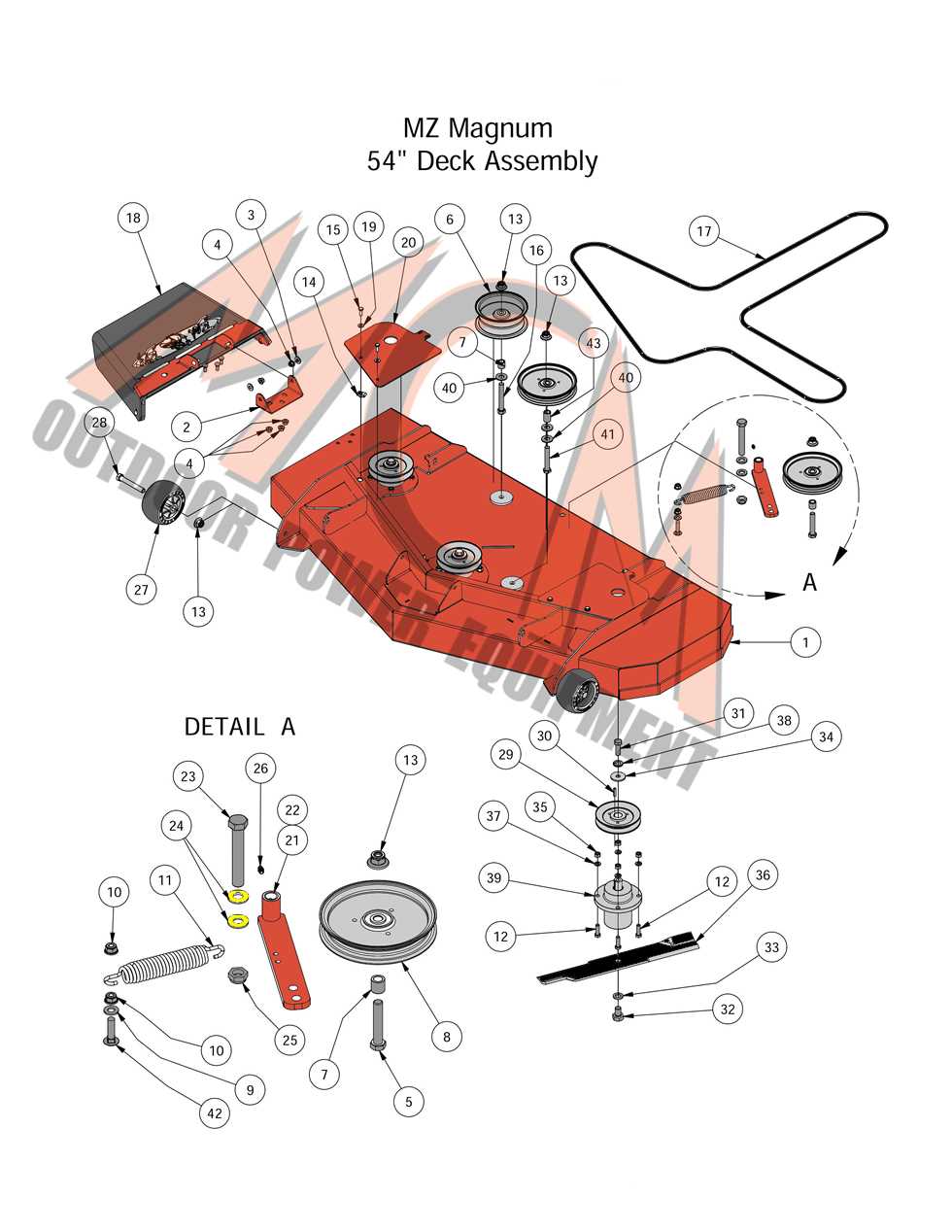

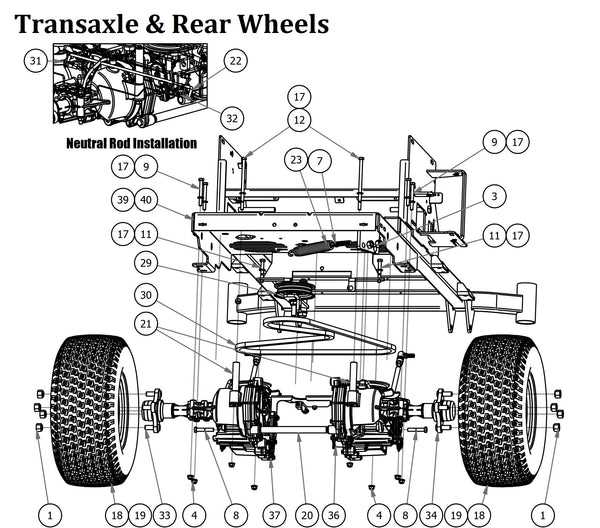

To effectively manage and maintain complex machinery, it is essential to have a clear understanding of how each component is arranged and functions within the system. A well-organized layout allows users to quickly identify each element, ensuring that any issues can be addressed without confusion or delay.

Each section of the equipment is designed to work in tandem with others, forming a cohesive whole. Knowing the placement and interrelation of different parts enhances the troubleshooting process and streamlines repairs. With a proper layout, technicians can focus on specific areas, minimizing the time spent on diagnostics.

The layout typically follows a logical structure, where the most critical components are easily accessible and clearly marked. This thoughtful arrangement not only aids in day-to-day operations but also facilitates maintenance routines, making it easier to spot wear and tear or potential faults.

By familiarizing oneself with this structured design, it becomes possible to approach any repair or replacement task with confidence, reducing the likelihood of errors and improving overall efficiency. Each part plays a specific role, and understanding its position within the system is key to ensuring reliable performance.

How to Identify Key Components

Accurately identifying essential elements within a system is vital for both troubleshooting and maintenance. When the components are clearly marked and easily recognizable, the process of diagnosing issues becomes more efficient and precise. A thorough understanding of each key element helps prevent errors and ensures that the right adjustments or replacements are made.

Start by familiarizing yourself with the most critical sections, such as power sources, control units, and any mechanisms responsible for movement or performance. These are typically the core areas that most issues stem from. Once you recognize these central elements, it becomes easier to identify how other components interact with them.

Use visual guides or reference materials to cross-check each component’s specifications. Labeling is often helpful in distinguishing one part from another. By comparing the actual items with their labeled counterparts in a reference, you can confirm their placement and role within the overall system.

Finally, hands-on experience plays a crucial role. As you work with the equipment more frequently, you will begin to recognize subtle differences and nuances between various elements. This knowledge builds over time, allowing you to efficiently identify key components in future maintenance or repair tasks.

Maintenance Tips for Bmz54kt740 Parts

Regular upkeep is essential for ensuring the longevity and reliable performance of any equipment. Proper maintenance can prevent unexpected failures and reduce the need for costly repairs. Understanding how to care for each component is key to preserving its functionality and preventing wear over time.

Routine Inspections

Performing regular inspections is one of the most effective ways to identify potential issues before they escalate. Check for signs of damage, corrosion, or wear, especially in high-use areas. Early detection of even minor issues allows for prompt repairs, reducing the risk of more severe problems down the line.

Cleaning and Lubrication

Keeping the equipment clean and properly lubricated ensures smooth operation and prevents unnecessary friction between moving parts. Use the recommended cleaning agents and lubricants, as certain materials may be sensitive to harsh chemicals. Regular maintenance of these systems helps to extend their lifespan and maintain peak performance.