Proper maintenance of pool equipment relies on knowing the structure and functions of each component. By familiarizing yourself with how different elements work together, you can ensure smooth operation and longevity of your system. A clear understanding of the layout helps in both troubleshooting and upgrading individual sections when necessary.

Key pieces of equipment play specific roles in keeping water clean and flowing efficiently. Understanding each part’s function allows you to identify problems early, reducing the likelihood of costly repairs. Whether you’re dealing with a malfunction or conducting routine upkeep, recognizing the arrangement of each element is crucial.

Learning about the setup of these systems empowers you to make informed decisions on repairs and replacements. Knowing what each section does and how they interact can save time and effort when the need arises to maintain or replace any piece of the setup. Proper care ensures that your pool equipment operates effectively for years to come.

Understanding the Pool System

Every pool setup relies on a network of interconnected components designed to keep the water clear and properly circulated. These essential elements work together to ensure that debris is removed, water is filtered, and the entire system operates smoothly. A solid understanding of each individual section helps in maintaining the system’s efficiency and extending its lifespan.

The operation of the entire mechanism depends on the careful design and functionality of each element. From the main pump to the directional valves, every component has a specific purpose in keeping the system balanced. By examining the arrangement of these parts, you can easily identify issues or areas that may need attention during routine maintenance.

Being familiar with the structure and interactions of the system allows for better management and troubleshooting. Whether you’re performing an inspection or dealing with a specific issue, knowing the role each element plays simplifies the process of keeping everything in working order. This knowledge ultimately leads to a more effective and reliable pool maintenance routine.

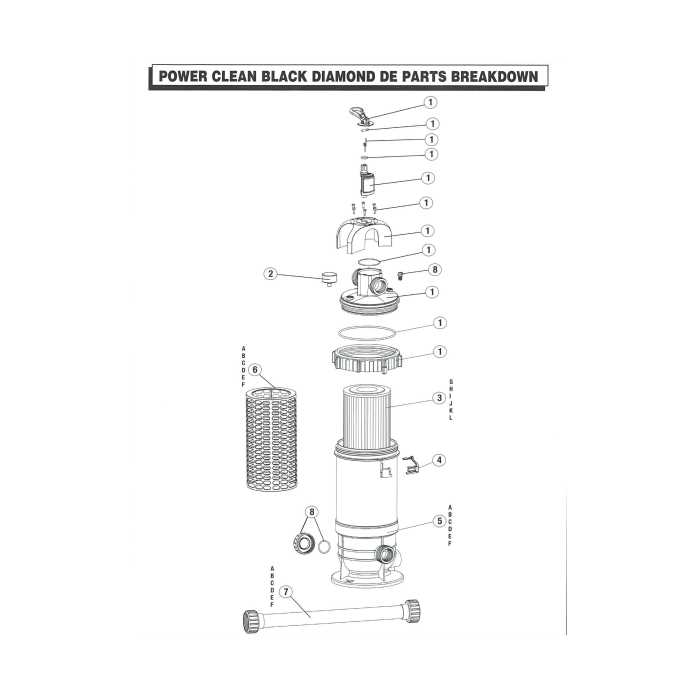

Key Components of Pool Cleaning System

A well-functioning water circulation system relies on a variety of components, each serving a distinct role in maintaining clean and balanced water. These key sections work in tandem to ensure that debris is effectively captured, water flows properly, and the system operates efficiently. Understanding the individual parts helps in managing maintenance tasks and identifying any issues that may arise.

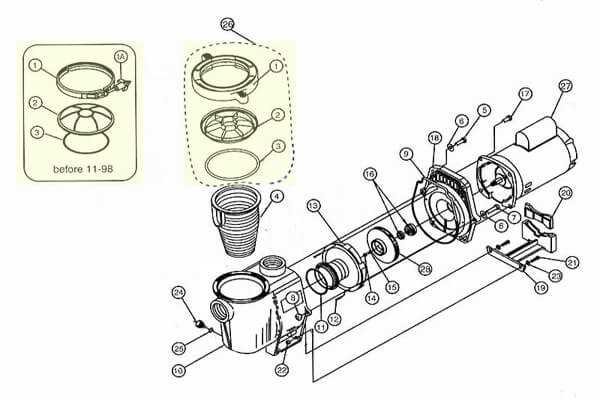

Main Pump

The main pump is one of the most crucial elements of the setup. It circulates the water, ensuring it flows through the system and passes through the cleansing components. Without a reliable pump, the system would fail to function properly, and water quality would suffer. Regular inspection and maintenance of the pump are essential for smooth operation.

Valves direct the flow of water to different sections of the system, allowing for efficient water movement. They control the path of water as it moves through various stages of the system, ensuring the right amount reaches the necessary components. Pressure gauges monitor the system’s performance, providing valuable insights into the pressure levels, which helps in identifying clogs or other issues that need attention.

How to Maintain Your Pool System

Proper maintenance is essential to keep your pool equipment in optimal working condition. Regular checks and upkeep of each component help prevent breakdowns and improve the overall performance of the entire system. By following a simple maintenance routine, you can ensure that your setup functions efficiently and lasts longer.

Regular Cleaning is one of the most important tasks. Over time, debris can accumulate in various sections, causing blockages or reduced performance. Cleaning components like the pump and valves should be done at regular intervals to avoid clogs and ensure smooth operation.

Another key aspect is monitoring pressure levels. Keeping an eye on the system’s pressure helps detect issues early on. Unusual readings could indicate that something is wrong, such as a clog or a malfunction in one of the parts. Routine checks allow for quick identification of potential problems, saving both time and money.

Lastly, replacing worn-out components is vital to maintaining the system’s efficiency. Parts that show signs of damage or wear should be replaced immediately to prevent more significant issues. Staying on top of necessary replacements ensures your equipment continues to operate without interruptions.