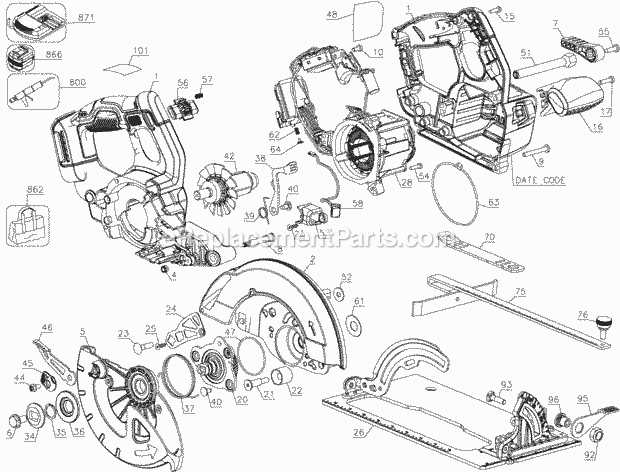

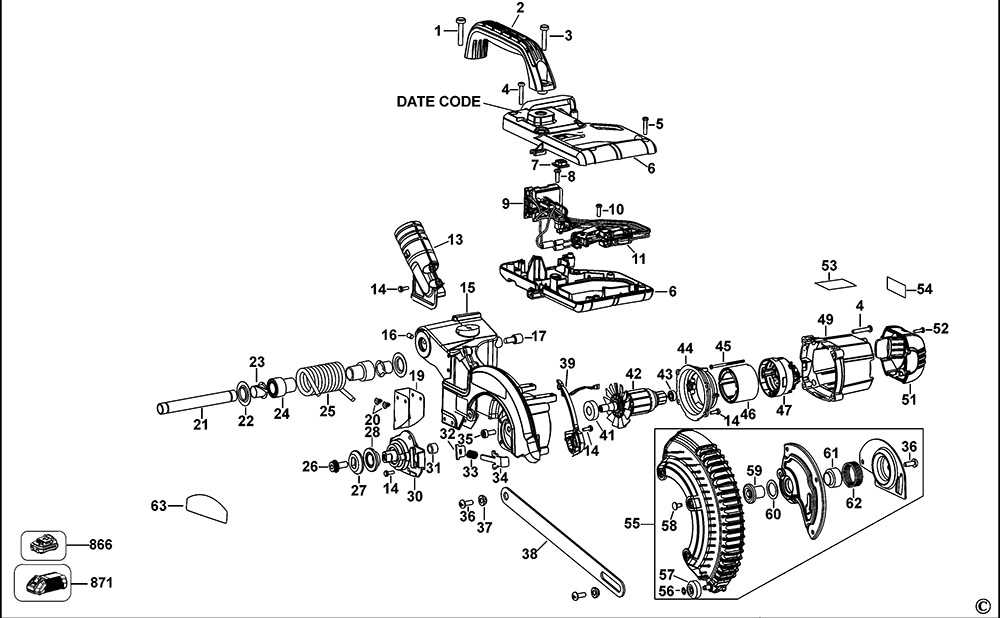

When dealing with household appliances, understanding their internal structure is key to performing effective repairs and maintenance. Knowing how to identify each part and its function ensures smoother operation and longevity of your devices.

Every complex appliance relies on a network of interconnected components. By familiarizing yourself with these elements, you can troubleshoot issues more efficiently and avoid costly repairs. A clear breakdown of the system allows for easier identification of faulty parts that may need attention.

Whether you’re looking to replace a malfunctioning element or simply enhance your knowledge of the device’s construction, having a visual representation of its layout is invaluable. It enables you to make informed decisions and complete any maintenance tasks with confidence.

Understanding DCS Parts and Functions

Modern control systems consist of various components that work together to monitor, manage, and regulate complex industrial processes. Each element plays a crucial role in maintaining system stability, ensuring accurate data collection, and enabling timely responses to changes. This section explores the essential components and their specific functions, providing insight into how each unit contributes to the overall performance of a control system.

Main Control Unit

The central hub of any system, this component processes data received from sensors and field devices, analyzes it, and then makes decisions based on predefined logic. It acts as the brain of the system, coordinating actions and issuing commands to other units in the network. By continuously comparing real-time inputs with desired setpoints, it ensures the system operates within safe and efficient parameters.

Field Instruments and Sensors

These devices are responsible for gathering real-world data, such as temperature, pressure, or flow rates. By converting physical measurements into digital signals, they provide accurate input to the system. The quality and reliability of these sensors are critical for maintaining proper system control and preventing issues caused by inaccurate readings.

Communication networks facilitate the exchange of information between various components, ensuring smooth data flow and coordination. These networks may include both wired and wireless systems that interconnect the control unit, sensors, and actuators, allowing for real-time adjustments and feedback.

Actuators are responsible for physically implementing control actions, such as opening valves, adjusting speeds, or changing pressure levels. Based on commands from the control unit, these devices enable the system to make tangible adjustments to the process, ensuring optimal operation at all times.

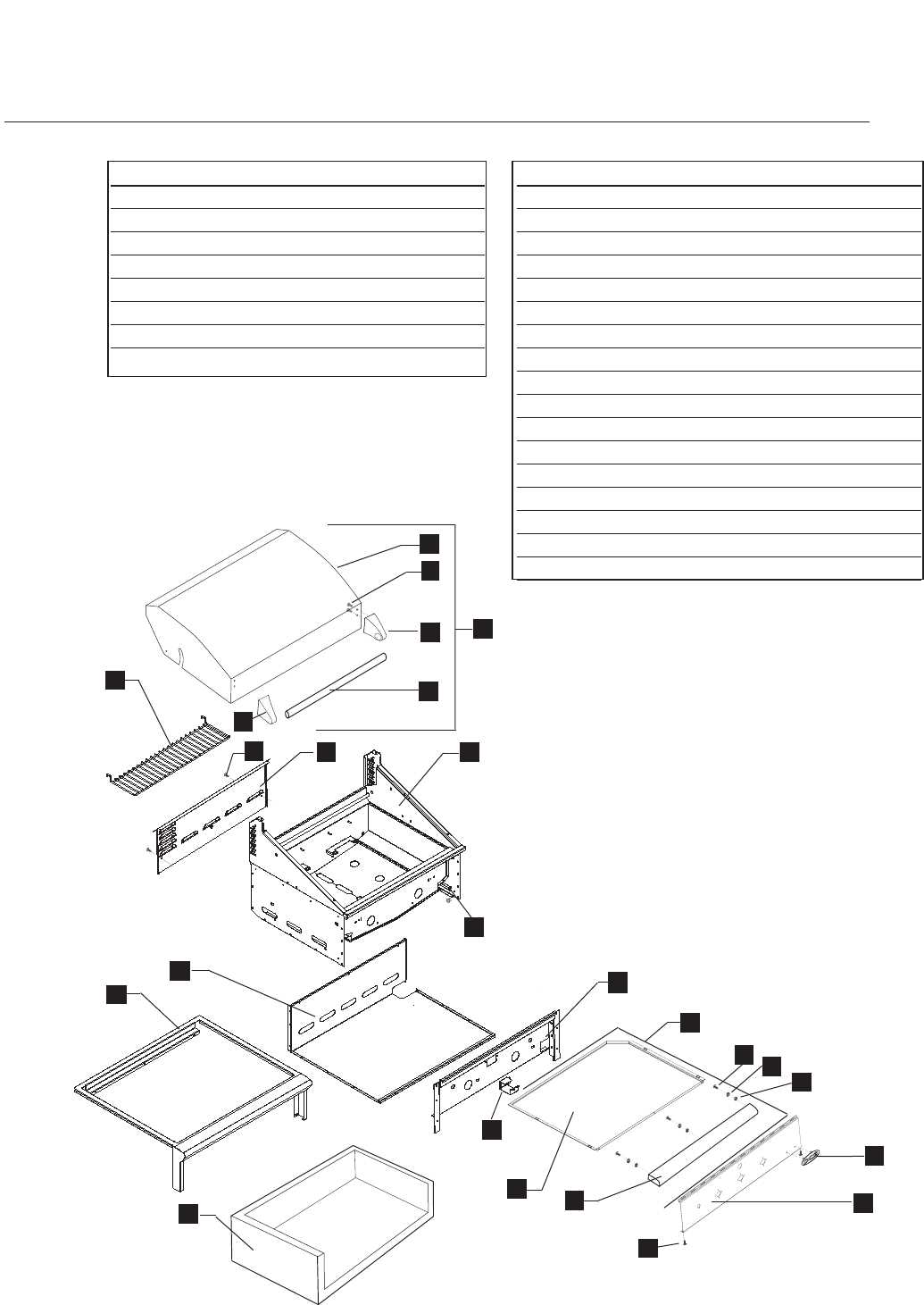

How to Use a DCS Parts Diagram

A technical illustration of a control system is an invaluable tool for anyone working with industrial processes. It provides a visual representation of the various elements that make up the system, offering a clear overview of their connections, relationships, and functions. Understanding how to interpret and use these schematics can significantly enhance troubleshooting, maintenance, and system optimization efforts.

Interpreting Symbols and Connections

Every system illustration uses standardized symbols to represent different components. These symbols are essential for quickly identifying each unit, whether it’s a sensor, actuator, or communication device. By familiarizing yourself with these icons, you can easily navigate the schematic and pinpoint the specific part you need to work with. Additionally, understanding the lines and connections between symbols helps visualize the flow of data or energy throughout the system.

Utilizing the Diagram for Troubleshooting

When issues arise within the system, a detailed schematic can serve as a crucial reference point for diagnosing the problem. By tracing the connections between components, you can identify potential points of failure. If a sensor is malfunctioning or a communication failure is suspected, the illustration will help you isolate the affected area, allowing for quicker and more accurate repairs.

Common Issues and Solutions for DCS Parts

In complex control systems, components can occasionally malfunction, leading to disruptions or inefficiencies. Understanding the most common issues and knowing how to address them can help maintain system performance and minimize downtime. This section covers typical problems that may arise in control systems and provides practical solutions to resolve them quickly and effectively.

Sensor Failures

Sensors are crucial for providing real-time data to the system. However, they can experience issues such as signal drift, incorrect calibration, or physical damage. A common symptom of a sensor failure is a discrepancy between the actual process value and the value displayed in the control interface. To solve this, first check the wiring connections and ensure there is no physical obstruction. If the sensor is still unresponsive, recalibrate it or replace it with a functioning unit. Regular maintenance and calibration can prevent most sensor-related issues.

Communication Interruptions

Loss of communication between system components can disrupt data flow, leading to incorrect system readings or delayed responses. This issue often arises due to faulty cables, network congestion, or equipment malfunctions. To address communication problems, start by inspecting the network connections, ensuring all cables are securely connected and free from damage. If using wireless networks, verify the signal strength and check for interference. Resetting routers or hubs and updating firmware can also help restore communication links.