When working with commercial kitchen machinery, understanding the intricate components that ensure smooth operation is essential. Each machine is made up of various elements, each serving a unique function to maintain efficiency and safety in the workplace. A clear understanding of these components can greatly improve both troubleshooting and regular maintenance tasks.

Knowing the structure of your equipment allows you to quickly identify wear and tear, preventing potential breakdowns before they occur. Proper care and knowledge can extend the lifespan of your machines and improve the overall performance of your kitchen.

Whether you’re replacing worn-out parts or simply want to familiarize yourself with the inner workings of your tools, learning the layout and function of each piece will help streamline your work processes. This guide will walk you through the various parts of your equipment, providing a helpful reference for future maintenance and repairs.

Understanding Commercial Food Machine Components

Commercial food processing machines consist of several key elements that work together to provide consistent, reliable operation. Each component is designed to fulfill a specific role, contributing to the overall functionality of the machine. Recognizing the purpose of these components allows for more efficient use and easier maintenance.

Key Functional Elements

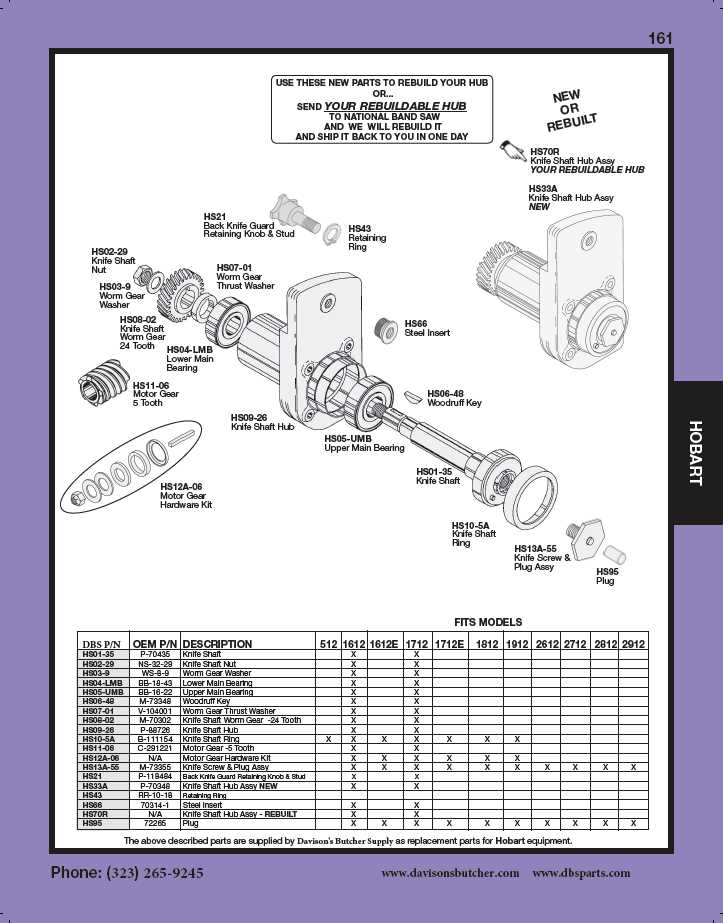

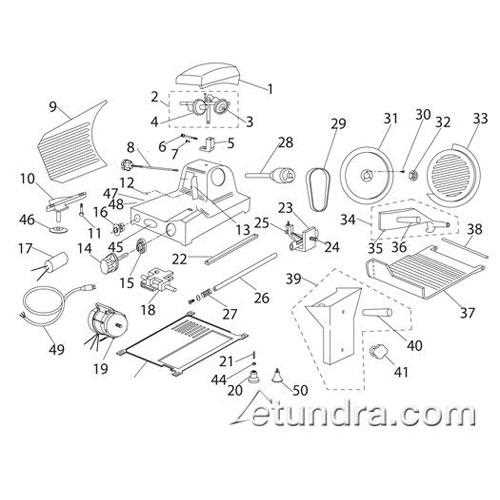

Machines of this type typically include a combination of rotating, cutting, and safety features. Components such as blades, motors, and drive mechanisms are essential to achieving the desired results. A strong understanding of how these pieces fit together ensures that users can operate the equipment smoothly and with minimal risk.

Maintenance and Troubleshooting

Regular inspection and cleaning of essential components can prevent major issues. Knowing which elements need attention, such as the cutting mechanism or drive system, can help identify problems early. Proper maintenance extends the life of the machine and keeps it running at peak performance.

By familiarizing yourself with the core components, you’ll be able to quickly identify potential issues, perform basic repairs, and keep the equipment in optimal working condition for years to come.

Identifying Key Parts in Commercial Food Machines

To properly maintain and operate a commercial food machine, it is crucial to recognize its essential components. Each element plays a vital role in the functionality and safety of the equipment. By understanding which parts are responsible for specific actions, users can ensure that the machine operates smoothly and efficiently.

The key components typically include the cutting mechanism, motor, and drive system. These elements are interdependent, and any issues with one can affect the overall performance of the equipment. Identifying these critical parts helps users troubleshoot and perform necessary repairs or replacements more effectively.

Additionally, safety features such as locking mechanisms, blade guards, and emergency shut-off switches are integral to preventing accidents. Knowing how these elements function together enhances not only the machine’s performance but also its safety during use.

How to Maintain Your Commercial Food Equipment

Proper maintenance of your commercial kitchen tools ensures long-lasting performance and reduces the risk of unexpected breakdowns. Regular care and cleaning are essential to keeping the machine in optimal condition, allowing it to operate efficiently and safely. Understanding the maintenance needs of each component is key to preventing wear and tear over time.

Regular cleaning is one of the most important tasks for preserving the functionality of your equipment. This includes wiping down surfaces, cleaning the blades, and ensuring that all moving parts are free from debris. Routine checks of the motor and drive system will also help identify any issues before they become major problems.

Inspecting safety features is equally crucial. Ensure that guards and locking mechanisms are intact and functioning properly to prevent accidents during operation. Lubricating moving components such as gears and bearings can also prevent excessive friction, extending the lifespan of the machine.

By implementing a regular maintenance schedule and addressing minor issues promptly, you can maximize the efficiency of your kitchen equipment and avoid costly repairs in the future.