How to Read Excavator Parts Diagrams

Benefits of Using PDF Diagrams for Maintenance

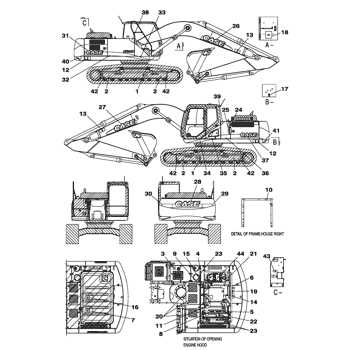

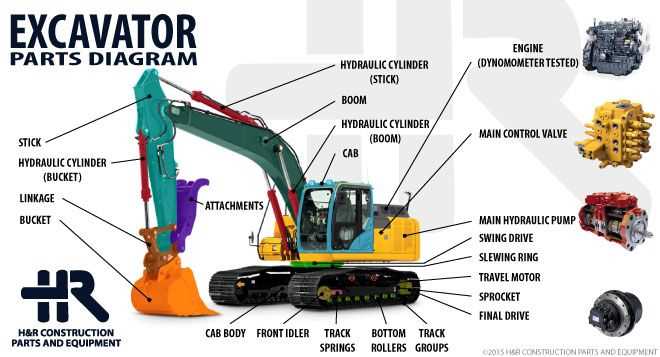

Understanding Excavator Components in Detail

Heavy machinery used in construction and mining operations consists of various complex elements that work together to ensure smooth and efficient performance. Each segment of the machine plays a critical role in the overall functionality, contributing to its strength, mobility, and precision. By studying these components, operators and technicians can optimize maintenance routines and troubleshoot issues more effectively.

Key Elements of the Machine

- Hydraulic System: This system powers various parts of the machine, including the arms, boom, and bucket. It uses fluid pressure to generate force, enabling movement and lifting capacity.

- Chassis and Tracks: These parts form the base of the machine, providing stability and mobility across rough terrain.

- Engine: The heart of the machine, the engine provides the power required to operate all functions.

- Control System: Operators use this system to manage the movement of all components, ensuring precise actions and safe operation.

Importance of Regular Maintenance

- Proper maintenance of hydraulic systems ensures consistent power delivery and prevents potential malfunctions.

- Inspecting the chassis and tracks helps maintain stability, avoiding issues that could lead to damage or poor performance.

- Regular engine checks guarantee optimal functioning, preventing overheating and ensuring long-term reliability.

- Routine control system evaluations ensure smooth operation and reduce the risk of system failures.

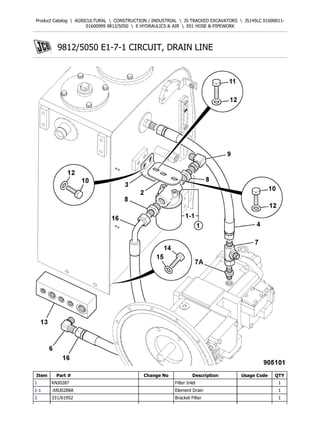

How to Use Excavator Parts Diagrams Effectively

Having a clear representation of machinery components is essential for efficient troubleshooting, maintenance, and repair. These illustrations provide valuable insights into the structure and function of each element, making it easier for operators and technicians to understand their roles and spot potential issues. Understanding how to read and utilize these visuals can save time and reduce errors during operations.

Steps to Maximize Understanding

- Familiarize with the Layout: Before diving into the specifics, take the time to understand the overall structure shown in the image. Recognize the main sections and how they relate to each other.

- Focus on Key Components: Pay attention to the highlighted elements that are most relevant to your task, whether it’s inspecting the powertrain or checking the hydraulic systems.

- Cross-Reference with Manuals: Use the visuals alongside technical manuals to ensure you’re interpreting the information accurately. This will help clarify any ambiguities.

Tips for Effective Usage

- Use a Digital Version: Accessing high-resolution, digital versions offers zooming capabilities, allowing you to see intricate details clearly.

- Mark Important Areas: Annotate or highlight critical components for quick reference during repairs or maintenance sessions.

- Maintain a Systematic Approach: Follow a step-by-step process based on the visual to ensure thorough checks and reduce the risk of overlooking any issues.

Benefits of Having a Parts Diagram PDF

Having a detailed visual representation of machinery components in a digital format offers numerous advantages. It allows for easy access to accurate information, which is essential for proper maintenance, quick repairs, and ensuring overall machine longevity. The ability to reference a comprehensive guide can simplify complex tasks and reduce downtime.

- Easy Accessibility: A digital version can be accessed from any device, anytime, which makes troubleshooting and repairs more convenient, especially in the field.

- High-Resolution Images: Clear, high-quality visuals provide a better understanding of intricate components, enabling technicians to identify issues faster and with greater accuracy.

- Enhanced Efficiency: With a visual reference, work is done more efficiently, reducing the likelihood of errors and ensuring tasks are completed in a timely manner.

- Space-Saving: Storing technical documents digitally eliminates the need for physical storage and makes organizing maintenance records more streamlined.

- Environmental Impact: Going digital reduces paper waste, supporting environmentally friendly practices in industries that rely heavily on printed technical documents.