Understanding the intricate system of components in a lawn care machine is essential for maintaining optimal performance. Every model consists of various parts that work in harmony to ensure smooth operation and longevity. Knowing how these elements are arranged and function together can greatly simplify repair and maintenance tasks.

Knowing the layout of each section and its corresponding pieces is crucial when diagnosing issues or planning replacements. Whether you’re a seasoned technician or a DIY enthusiast, having a clear visual representation of the machine’s setup can save time and effort during troubleshooting.

In this guide, we will explore the key elements that make up these devices, providing a detailed breakdown that will help identify the right pieces for any necessary repairs. With the right knowledge, you’ll be equipped to keep your equipment running like new for years to come.

Understanding the John Deere D160 Parts

Every lawn mower is made up of a variety of interconnected elements, each with a specific role in the machine’s overall function. A deep understanding of these components is vital for effective maintenance and troubleshooting. By familiarizing yourself with the essential pieces, you can more easily identify any issues and address them before they affect performance.

Key Components and Their Functions

At the heart of any mower, the engine, transmission, and cutting deck are the most critical areas. The engine powers the mower, while the transmission controls its speed and movement. The cutting deck houses the blades, which are responsible for trimming the grass. Understanding how these parts work together will give you a better grasp of the machine’s inner workings and help you maintain it more efficiently.

Common Wear and Tear Areas

While all components are important, certain parts are more prone to wear over time due to frequent use. The belts, blades, and filters often need to be replaced or cleaned regularly to ensure smooth operation. Knowing which elements are most likely to show signs of damage allows for proactive care, reducing the chances of unexpected breakdowns.

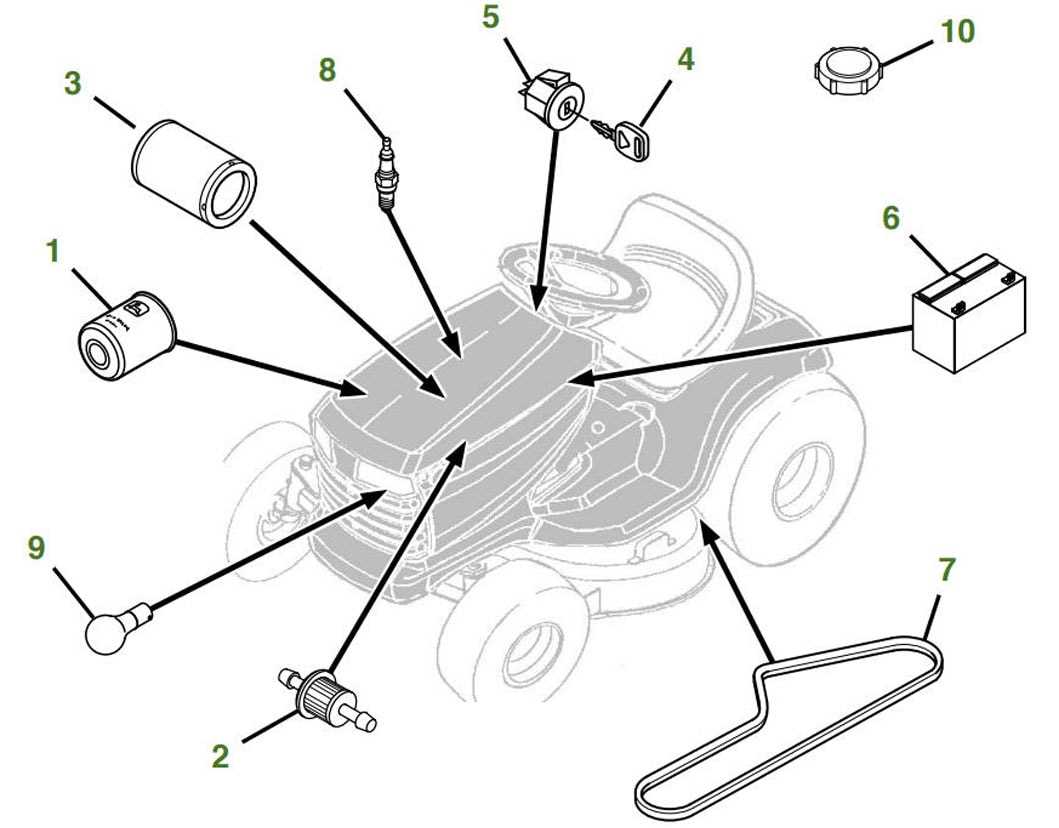

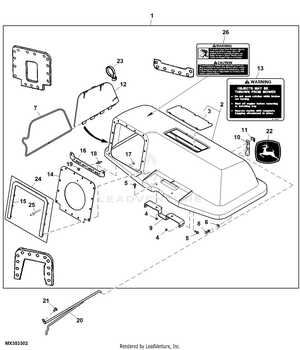

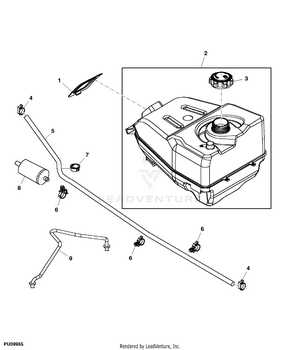

How to Read the D160 Parts Diagram

Understanding how to interpret technical illustrations of machinery is crucial for effective maintenance and repair. These detailed drawings provide a visual reference for all the components and their placement within the system. By familiarizing yourself with the structure and symbols, you can quickly locate parts, understand their connections, and identify where problems may arise.

The key to reading these visuals lies in recognizing the different sections and how they correspond to the actual machine layout. Each component is labeled with a specific code or number, which links to a corresponding list or reference guide. This guide will often include part names, numbers, and specifications, making it easier to order replacements or perform specific maintenance tasks.

Additionally, pay attention to any markings or symbols that indicate the orientation of certain components. These can be critical when reassembling or replacing parts to ensure that everything is aligned and functioning correctly. By practicing with these diagrams, you’ll gain confidence in navigating the technical details of your mower’s setup.

Common Replacement Parts for John Deere D160

Maintaining the longevity and efficiency of a lawn care machine often involves replacing worn-out or damaged components. Some parts are more susceptible to wear due to constant use, and addressing these areas promptly can help prevent larger issues down the road. Knowing the most common replacement parts ensures you’re always prepared for regular upkeep and unexpected repairs.

Belts are one of the most frequently replaced items. These are essential for transferring power between the engine and various other components. Over time, belts can stretch, crack, or wear out, requiring regular inspection and replacement to avoid breakdowns.

Blades are another crucial component that requires attention. Dull or damaged blades will affect cutting efficiency and can cause uneven results. Replacing the blades ensures the machine performs optimally, providing a cleaner, more uniform cut.

Other common replacements include filters and spark plugs, which need regular maintenance to keep the engine running smoothly. Clogged filters can hinder airflow and fuel efficiency, while worn-out spark plugs can lead to starting problems or poor engine performance.