Every complex machine consists of numerous interconnected elements that work in harmony to ensure smooth functionality. Understanding the layout and organization of these components is essential for efficient operation and maintenance.

Having a clear visual representation of the structure allows operators and mechanics to quickly identify each part and its role. This knowledge not only helps in repairs but also contributes to preventive care and optimal machine performance.

In this guide, we will explore the essential elements that make up this particular equipment, providing insights into their functions and how to effectively navigate the detailed visual reference for troubleshooting and upkeep.

Understanding Machine Components

Each mechanical system is built from a variety of individual elements, each playing a crucial role in the overall functionality. Recognizing the specific purpose of these components helps to maximize the performance and efficiency of the equipment.

Critical elements within the structure work together, from the engine to the auxiliary systems, ensuring that everything operates seamlessly. Understanding these parts allows operators to better care for the machine and identify any potential issues early on.

By studying the internal structure, one can gain valuable insights into how each component contributes to the overall function. This knowledge also aids in making informed decisions when it comes to repairs, replacements, or upgrades.

Key Components and Their Functions

Each machine consists of multiple critical components that work in unison to achieve optimal performance. Understanding the function of each of these elements is essential for effective operation and maintenance.

Below are some of the key components typically found in such machinery:

- Engine: The core of the machine, responsible for providing power to all other systems.

- Transmission: Transmits power from the engine to the wheels or working mechanisms, allowing movement and operation.

- Hydraulic System: Provides the necessary force to operate various attachments and tools, ensuring smooth performance during tasks.

- Control Panel: The interface through which the operator manages machine settings and monitors performance.

- Frame: The structure that supports all components, ensuring stability and durability during use.

Each part plays a vital role in the machine’s operation. Recognizing their function helps to understand the overall system and how they contribute to the equipment’s effectiveness and reliability.

How to Read the Component Layout

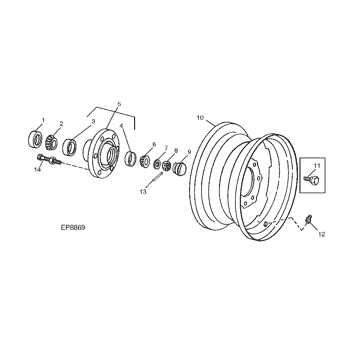

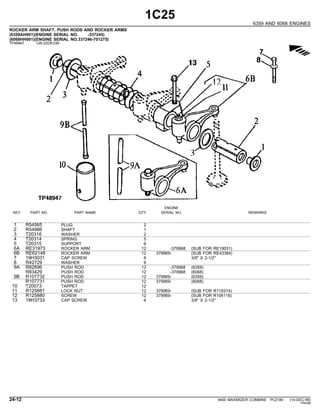

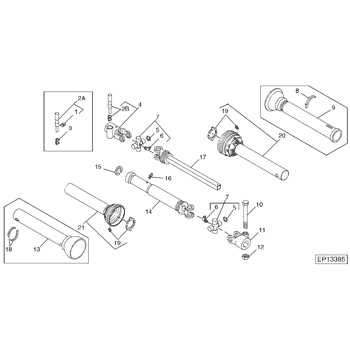

Understanding how to interpret visual representations of machinery is essential for efficient maintenance and troubleshooting. These detailed illustrations provide a clear view of each individual element, making it easier to locate and identify specific components.

To read such a layout effectively, start by familiarizing yourself with the legend or key, which typically explains the symbols and notations used. Each part is marked with a unique code or label, which can be cross-referenced with a list for further details.

Focus on identifying major sections such as the engine, transmission, and control systems. Once you know where each system is located, you can quickly trace the connections and understand how each element interacts with the others. This method allows for swift identification of any malfunctioning parts or areas in need of maintenance.

Step-by-Step Guide to Navigation

Properly navigating a component layout is crucial for identifying and understanding the elements within a machine. By following a systematic approach, you can quickly find the parts you need for maintenance or repair.

Step 1: Start by locating the overview section, which provides a broad view of the entire system. This will give you an understanding of the overall structure and organization.

Step 2: Next, focus on identifying major components such as the engine, transmission, and hydraulic systems. These are usually highlighted and placed in key areas for easy reference.

Step 3: Use the reference key to cross-check component numbers and labels. This will help you match the visual representation to the corresponding parts list.

Step 4: Once you have a clear understanding of each element’s location, follow the pathways or connections to see how they interact with one another. This will help you diagnose any issues or plan repairs more effectively.

Maintaining Your Equipment

Regular maintenance is key to ensuring the longevity and optimal performance of your machinery. By following a consistent care routine, you can prevent potential breakdowns and ensure that all components function smoothly.

Routine Inspections

Start by performing regular checks of the key systems, including the engine, transmission, and hydraulic systems. Look for any signs of wear, loose connections, or leaks that may require attention. Early identification of these issues can save time and money in the long run.

Cleaning and Lubrication

Keep all moving parts clean and well-lubricated to prevent friction and premature wear. Be sure to use the recommended cleaning agents and lubricants for your specific equipment to avoid damage. Proper cleaning also ensures that dust and debris do not interfere with the machine’s efficiency.