Maintaining and repairing garden machinery can often seem challenging without a clear understanding of its individual components. When working with tilling equipment, knowing how each part functions is essential for ensuring long-term reliability and efficiency. This section aims to provide a detailed guide on the essential elements that make up a typical cultivator.

By examining the various sections of a garden machine and their specific roles, you can gain a better understanding of how to manage any issues that arise. Whether you’re replacing damaged elements or simply performing routine maintenance, a solid grasp of the equipment’s layout will make the process smoother and more effective.

Exploring these crucial components and their arrangements can help you troubleshoot problems, enhance performance, and prolong the life of your tool. Having a visual guide can further simplify the process, allowing you to identify and replace parts with ease.

Understanding Garden Equipment Components

Proper maintenance and efficient operation of any gardening tool require a deep understanding of its individual components. Each part plays a vital role in ensuring the smooth functioning of the machine, and recognizing how they interact can help you troubleshoot issues or replace damaged elements. This section will guide you through the essential parts that contribute to the effectiveness of a cultivator.

Key Elements of the Machine

The engine, wheels, and working mechanism form the core of the equipment. The engine is responsible for providing power, while the wheels ensure mobility and control. The working mechanism is what performs the task of loosening soil and cultivating the ground. Understanding these key parts will help you ensure that each component is functioning properly.

Additional Features for Enhanced Performance

There are other supporting parts that contribute to the overall effectiveness, such as the handlebar, transmission system, and various levers. These features provide comfort, ease of use, and better handling, allowing you to operate the machine with precision and efficiency. Identifying and maintaining these components is crucial for achieving optimal results in your gardening tasks.

Identifying Key Components of Cultivators

Recognizing the main elements of your gardening machinery is essential for effective maintenance and troubleshooting. By identifying the crucial components that work together to drive and control the tool, you can ensure proper operation and prevent common issues. Understanding these components allows you to carry out necessary repairs or replacements when needed.

The engine serves as the heart of the equipment, generating the power needed for movement and operation. The tines, located at the front of the machine, are responsible for breaking up the soil. Along with the transmission system, these parts work in tandem to provide optimal performance in your gardening tasks.

Other important components include the handles for user control, the wheels for mobility, and safety features designed to protect the operator during use. By familiarizing yourself with these parts, you can efficiently diagnose any malfunction and maintain the machine in peak condition.

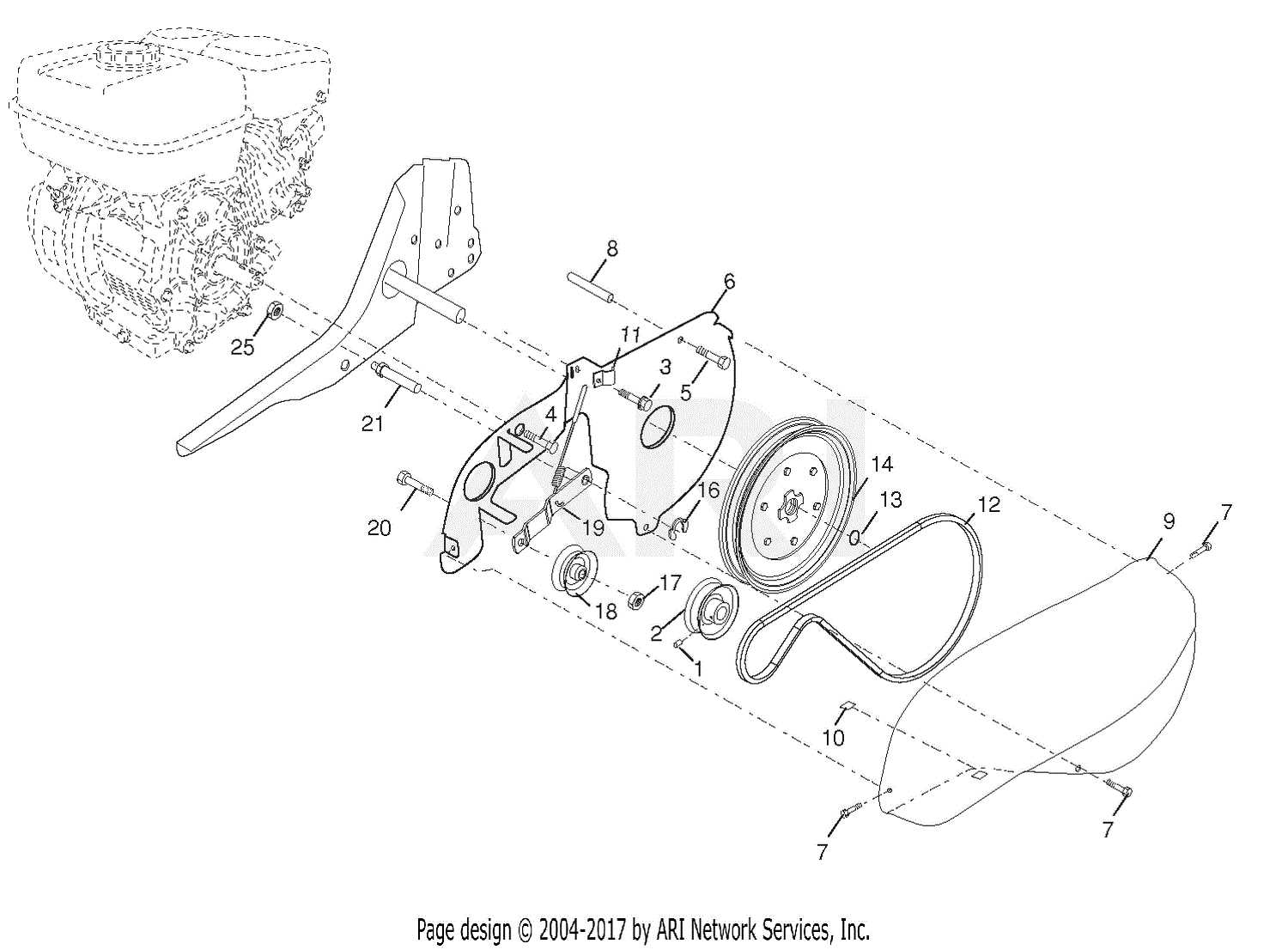

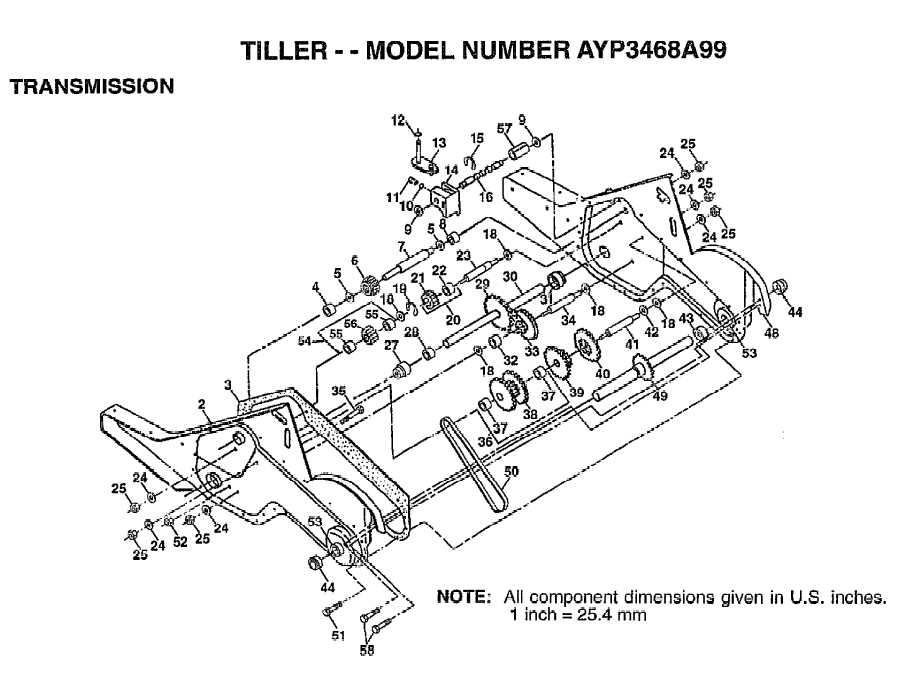

How to Read Equipment Component Illustrations

Understanding visual guides for your garden machinery is crucial for proper maintenance and repair. These illustrations provide a detailed view of each part’s placement and function, helping you quickly identify components that may need attention. Knowing how to interpret these guides allows you to troubleshoot issues with ease and find the right replacement parts.

The first step in reading such illustrations is to familiarize yourself with the key symbols used. Each component will be labeled with a specific number or letter, which corresponds to a list of names or descriptions. Pay attention to the orientation and grouping of parts to understand how they interact with one another.

Breaking down the sections of the guide is also important. For example, separate areas may show the different systems in the equipment, such as the engine, transmission, or control mechanisms. By examining these groups, you can pinpoint the exact part that needs to be repaired or replaced, making the process much more efficient.