In automotive engineering, effective air control is crucial for optimal engine performance. The components responsible for regulating airflow directly influence fuel efficiency and engine response. These systems play an essential role in maintaining smooth operation, ensuring that the air entering the engine is properly managed and controlled.

The mechanisms involved are not only important for the car’s performance but also for its longevity. Understanding how each element contributes to this process can help with troubleshooting and maintenance, leading to better overall care for your vehicle.

In this article, we will break down the essential elements of these airflow systems, focusing on their functions, interconnections, and how they affect engine operation. By exploring their roles, you’ll gain valuable insights into the inner workings of your car’s air management system.

Throttle Body Overview and Components

In modern internal combustion engines, the system responsible for regulating airflow is a vital component for controlling fuel delivery and engine performance. This assembly ensures the proper mixture of air and fuel is delivered to the engine cylinders, enabling efficient combustion. Understanding how this system works is key to maintaining optimal engine function and diagnosing potential issues.

Key Functions of the Airflow System

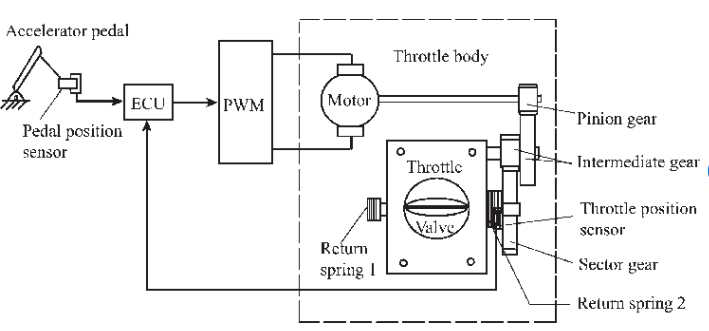

The primary role of this system is to control the volume of air entering the engine. By adjusting the airflow, it ensures that the correct amount of air is mixed with fuel for combustion. A well-functioning mechanism directly influences fuel efficiency, throttle response, and overall engine performance. Components like sensors and valves play crucial roles in monitoring and controlling air intake based on various conditions, such as engine speed and load.

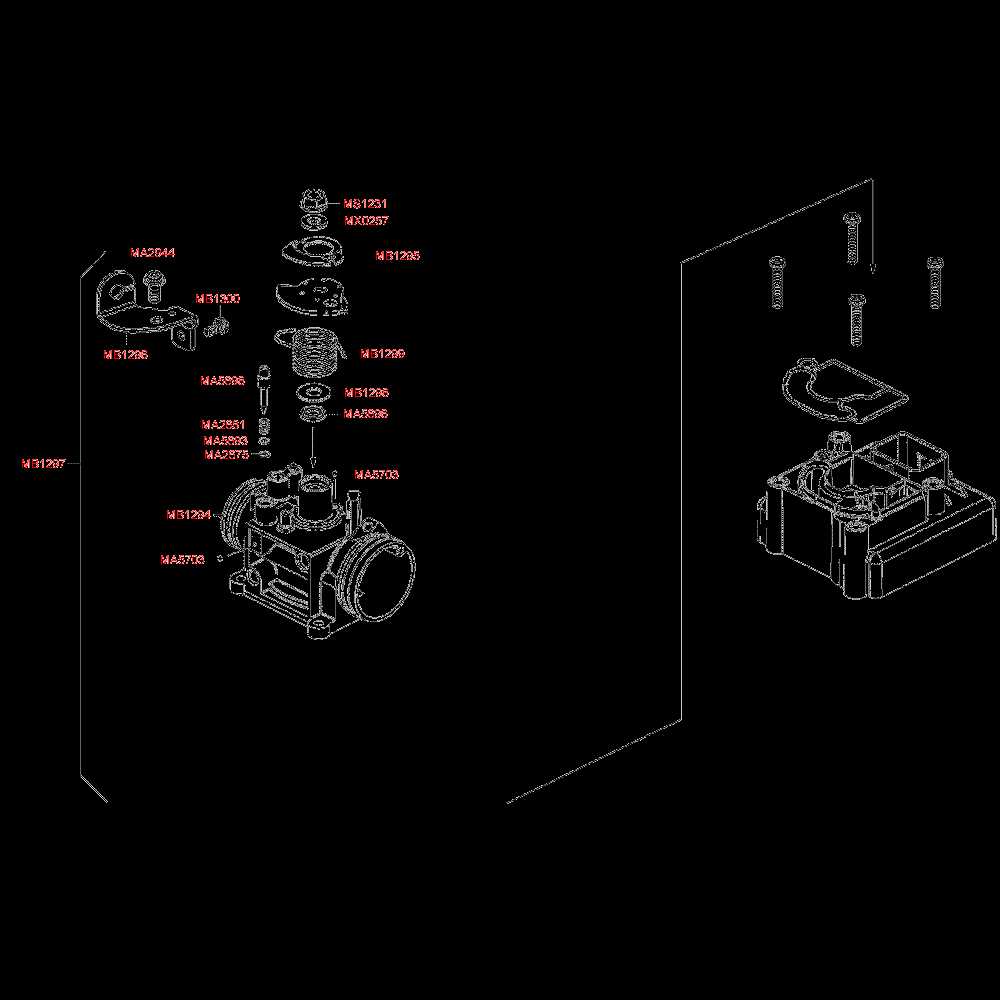

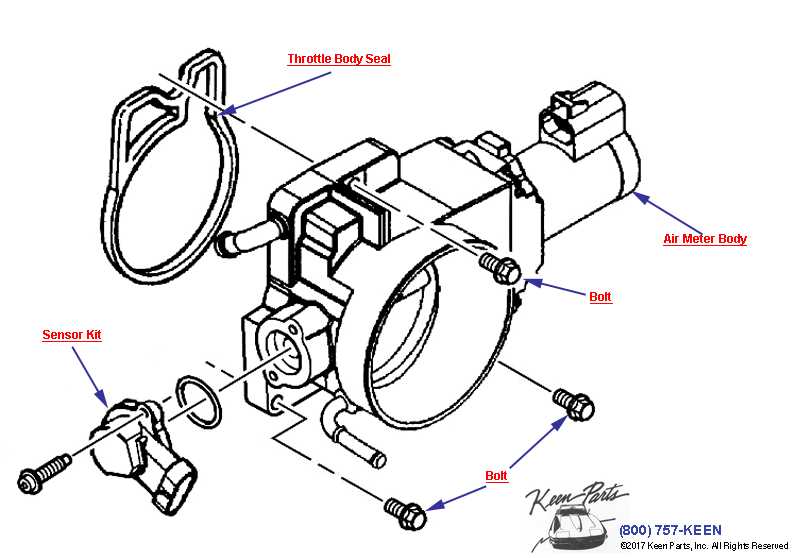

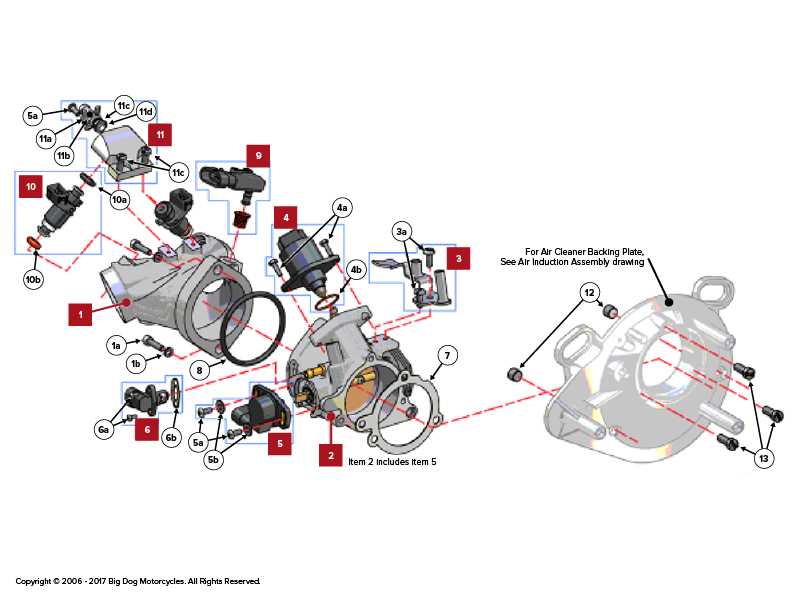

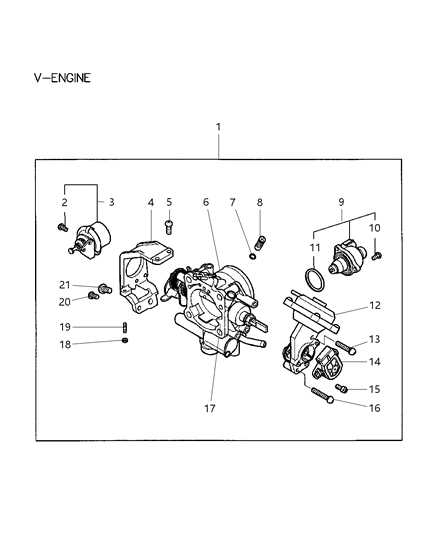

Components Involved in Airflow Regulation

Several elements work together to manage the flow of air into the engine. The key components include the actuator, which adjusts the valve, and various sensors that monitor airflow and pressure. Additionally, a housing assembly encapsulates these parts to protect them from external elements. Regular inspection and maintenance of these components are necessary to avoid performance issues, as even minor malfunctions can lead to reduced efficiency or engine stalling.

Key Functions of Throttle Body Parts

The system responsible for regulating the flow of air into the engine plays a crucial role in controlling combustion efficiency and vehicle performance. By adjusting the amount of air that enters the engine, it ensures that the engine receives the optimal mixture of air and fuel. This balance directly affects fuel consumption, engine responsiveness, and overall power output.

One of the most important functions is the ability to precisely control airflow based on driving conditions. This is achieved through various mechanisms, such as sensors and actuators, which monitor and adjust air intake in real-time. Additionally, components like the air intake valve regulate the air volume, while sensors track changes in air pressure and temperature to make constant adjustments to maintain engine efficiency.

The collaboration of these elements enables the engine to perform under a wide range of conditions, from idling to full acceleration. A malfunction in any of these components can lead to poor fuel economy, erratic idling, or even engine failure, highlighting the importance of proper maintenance and timely repairs.

Common Issues with Throttle Body Components

The system responsible for regulating the flow of air into the engine can encounter a variety of issues that affect overall vehicle performance. These issues often arise due to wear, contamination, or sensor malfunctions, which disrupt the delicate balance needed for smooth engine operation. Understanding these problems is key to diagnosing and addressing them effectively.

Clogging and Contamination

One of the most common issues is the buildup of carbon deposits or dirt within the system. Over time, this accumulation can obstruct airflow, causing rough idling, stalling, or poor throttle response. Regular cleaning of the air intake and associated components is essential to prevent this issue. Contamination can also affect the sensors, leading to incorrect readings and poor fuel efficiency.

Sensor and Actuator Malfunctions

Faulty sensors or actuators can cause inaccurate airflow measurements or improper adjustments to the air intake. This can lead to engine hesitation, poor acceleration, or an increase in fuel consumption. In some cases, a malfunctioning sensor may trigger the “Check Engine” light, signaling the need for a thorough inspection and repair.