Proper maintenance and efficient repairs rely on having a clear understanding of the individual elements within your machine. A well-organized reference of each component is essential for both troubleshooting and part replacements. When you know where everything belongs, you can handle repairs with confidence, ensuring that your tool operates optimally.

Identifying the right piece is the first step in any repair process. A detailed guide will help you pinpoint specific areas of concern, making it easier to address issues without unnecessary guesswork. Knowing the layout and function of each piece ensures that any malfunction can be quickly resolved.

Routine care becomes much easier when you have a visual reference to guide your actions. Regular checkups and timely fixes extend the lifespan of your machine and improve overall performance. Whether you are a beginner or experienced user, having access to a comprehensive layout enhances your ability to take control of repairs effectively.

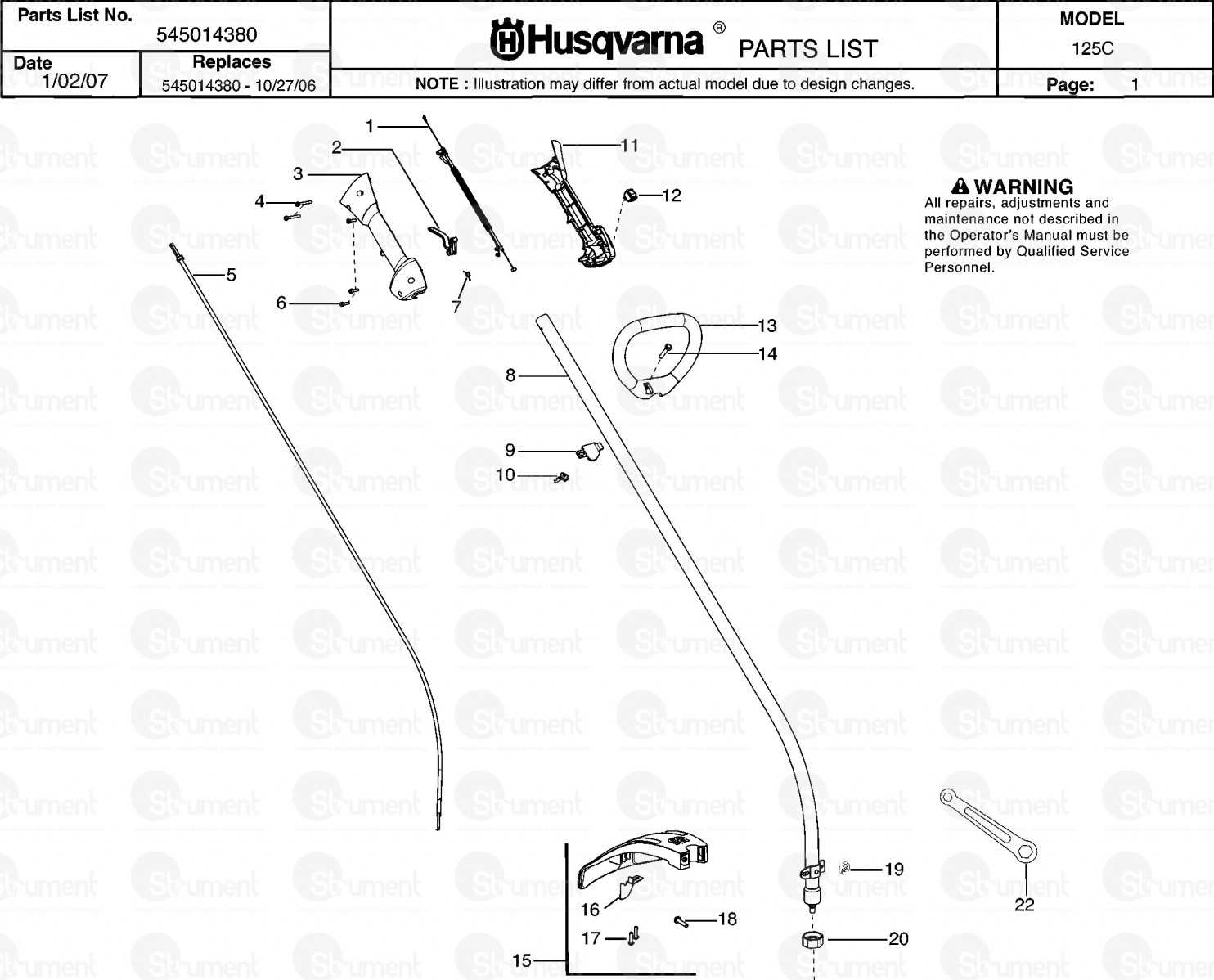

Understanding the Components Layout

In any mechanical tool, each individual piece has a specific function that contributes to the overall performance. A clear layout of these elements helps users recognize how everything fits together and operates as a whole. By understanding the organization of key components, it becomes easier to maintain, troubleshoot, and repair the equipment.

When you have a visual representation of each section, you can quickly identify potential issues or missing pieces. This clarity is essential for any repair work, whether it’s replacing worn-out parts or performing routine maintenance. Knowing the exact position and role of each element ensures efficient handling and minimizes errors.

Such an organized system not only facilitates repairs but also enhances the user experience. With a comprehensive understanding of the tool’s internal structure, users are empowered to handle the equipment with confidence, ultimately prolonging its lifespan and optimizing its functionality.

How to Identify Components on the Layout

Being able to recognize individual elements in a mechanical layout is crucial for effective maintenance and repairs. Each part plays a vital role in the operation of the equipment, and understanding their placement allows you to address issues accurately. A visual reference simplifies this task by providing a clear view of how everything fits together.

Start by focusing on the shape, size, and connection points of each piece. The layout typically highlights these features, making it easier to match parts with their corresponding locations on the tool. Pay attention to any labels or numbers, as these often correspond to specific components that may need replacement or inspection.

Once you familiarize yourself with the structure, it becomes easier to pinpoint problems and determine which parts require attention. This methodical approach saves time and helps ensure that you select the correct replacement parts or perform the necessary adjustments with precision.

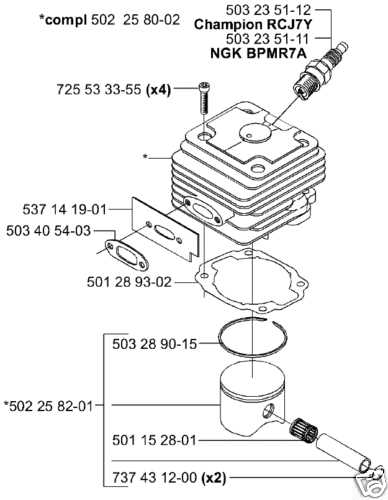

Common Issues and Part Replacements

Over time, mechanical tools can experience wear and tear, leading to certain common issues. Identifying these problems early and knowing the correct replacements can save both time and money. Regular inspection and prompt action are key to keeping equipment in optimal condition.

Frequent Failures

Some of the most common problems include damaged seals, clogged filters, or worn-out drive components. These issues typically affect the efficiency of the tool and can cause it to malfunction if left unchecked. Identifying these failures is easier when you have a clear understanding of the tool’s structure and its components’ roles.

Replacing Worn Components

Once a part is identified as faulty or worn, replacing it promptly is crucial for maintaining performance. Ensure that you are using the correct replacement pieces that match the specifications outlined in the visual reference. Replacing worn components with quality alternatives will extend the life of your tool and maintain its efficiency.