When working with small engines, it’s essential to have a clear understanding of the internal systems that keep them running smoothly. Proper maintenance and repairs rely heavily on knowing the different components and how they fit together. This knowledge is key for anyone looking to optimize engine performance or troubleshoot issues effectively.

In this guide, we will explore the intricate network of essential elements found in the fuel delivery system. By reviewing the layout and functionality of each element, you will gain a better understanding of how these components interact to provide optimal engine operation.

Learning to identify these pieces is crucial for those looking to maintain or repair their equipment. Whether you’re tackling a simple fix or performing regular upkeep, knowing how each component plays its role will allow for quicker diagnosis and more efficient repairs.

Understanding the Carburetor Components

Engines rely on a combination of elements to ensure fuel is delivered in the right quantities and at the right time for combustion. These components are responsible for regulating airflow and fuel mixture to optimize performance. Each part plays a crucial role in the overall functioning of the system, ensuring smooth operation and fuel efficiency.

The system includes a variety of essential pieces, such as the choke, throttle, and fuel bowl, which work together to control the engine’s power output. Understanding how each of these components interacts is vital for troubleshooting issues, performing maintenance, or making repairs.

By familiarizing yourself with the design and layout of these elements, you can gain a deeper appreciation for how engines manage fuel intake. This knowledge allows for quicker repairs and more effective maintenance, ensuring your equipment runs efficiently for longer periods.

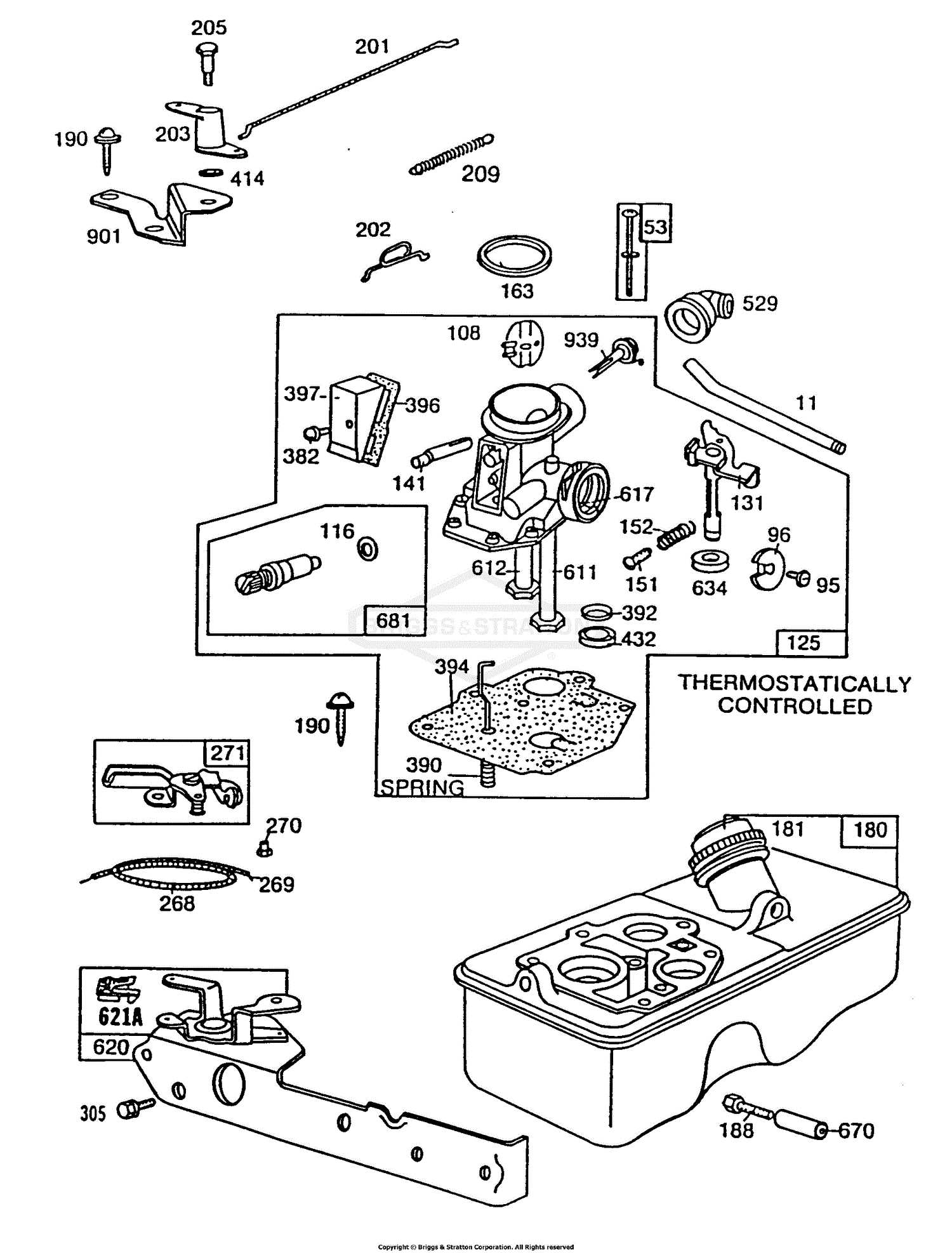

Identifying Key Parts in the Diagram

When examining the layout of a fuel delivery system, it’s essential to recognize the critical elements that contribute to its functionality. Understanding where each component is located and how it interacts with others helps ensure the system operates smoothly. By identifying these key components, you can pinpoint issues more efficiently and perform necessary maintenance or repairs with greater accuracy.

Essential Components of the System

Among the most important elements are the fuel bowl, which stores the fuel mixture, and the throttle valve, which regulates the engine’s power output. The choke helps control airflow during startup, while the float maintains the correct fuel level in the bowl. Recognizing these components and their placement is critical when working with the system.

Visualizing the Relationships

Once you’ve identified the individual parts, understanding their relationships is key. The needle valve controls fuel flow into the bowl, while the air intake regulates airflow into the system. Each piece serves a specific function, and the entire setup works together to maintain the correct fuel-to-air ratio for optimal engine performance.

How to Read a Carburetor Diagram

Interpreting an engine fuel system layout requires a clear understanding of the symbols and connections that represent various elements. A well-drawn schematic helps you visualize how each part fits into the overall system, making it easier to identify components, troubleshoot problems, and follow proper assembly or disassembly steps.

The first step in reading such a layout is to familiarize yourself with the key symbols used. Components like valves, hoses, and air filters are often represented by standardized shapes or labels. Once you know what each symbol means, you can begin to trace how the fuel flows through the system, noting how parts like the choke or throttle are connected to each other.

Additionally, pay attention to the direction of arrows, which often indicate airflow or fuel movement. This will help you understand how each part functions within the system, allowing you to troubleshoot more effectively or replace faulty elements as needed.

Step-by-Step Guide for Assembly

Assembling an engine fuel system requires careful attention to detail and following a logical sequence to ensure that all components are correctly positioned. Each element plays a vital role in the engine’s performance, and improper assembly can lead to malfunctions or inefficiency. By following these steps, you can ensure a successful rebuild or reassembly of the system.

Preparation and Initial Steps

- Ensure you have all necessary tools and components before starting the process.

- Clean all components thoroughly to remove dirt or debris that could affect the assembly.

- Check for any damaged parts that need to be replaced before assembly.

Assembly Process

- Start by attaching the fuel bowl to the base of the assembly, ensuring it is tightly secured.

- Next, connect the throttle valve to the appropriate linkage, making sure it moves freely.

- Install the choke mechanism, paying close attention to its alignment with the intake.

- Place the float into the fuel bowl, ensuring it is positioned correctly to control the fuel level.

- Finally, check that all hoses and connections are firmly attached and there are no leaks.

By following these steps, you can ensure that the fuel system is properly assembled and ready for use. Always verify each part’s functionality before starting the engine to avoid any potential issues.

Maintaining Engine Fuel Systems

Regular maintenance is essential to ensure the longevity and proper functioning of any engine. By keeping the fuel system in optimal condition, you can prevent costly repairs and improve overall engine performance. Proper upkeep involves cleaning, inspecting, and replacing key components as needed to maintain fuel efficiency and prevent clogging or leaks.

Cleaning the Fuel System

Start by regularly cleaning the fuel delivery components to remove dirt, debris, and any build-up that can cause blockages. This includes flushing out any fuel lines and inspecting the air intake for obstructions. Cleaning prevents inefficiencies that may arise from clogged passages and ensures smooth fuel flow throughout the system.

Inspecting and Replacing Components

Over time, some elements of the fuel system may wear out or degrade. It’s important to inspect parts like the needle valve, float, and throttle linkage for any signs of damage or wear. Replacing these components promptly can prevent larger issues down the road and help maintain optimal engine performance.