When it comes to lifting heavy objects, the mechanism used plays a crucial role in ensuring safety and efficiency. Each tool consists of various elements that work in harmony, with each piece contributing to the overall function. By understanding these components, users can ensure proper usage and maintenance.

Identifying each component within the lifting mechanism is essential for anyone who wants to handle such equipment safely. Recognizing how each part interacts helps prevent errors during operation and aids in troubleshooting when issues arise.

Proper assembly and regular checks of the different elements are vital in maintaining the tool’s performance and longevity. Whether for simple repairs or routine maintenance, knowing the structure of the tool can save time and avoid unnecessary replacements.

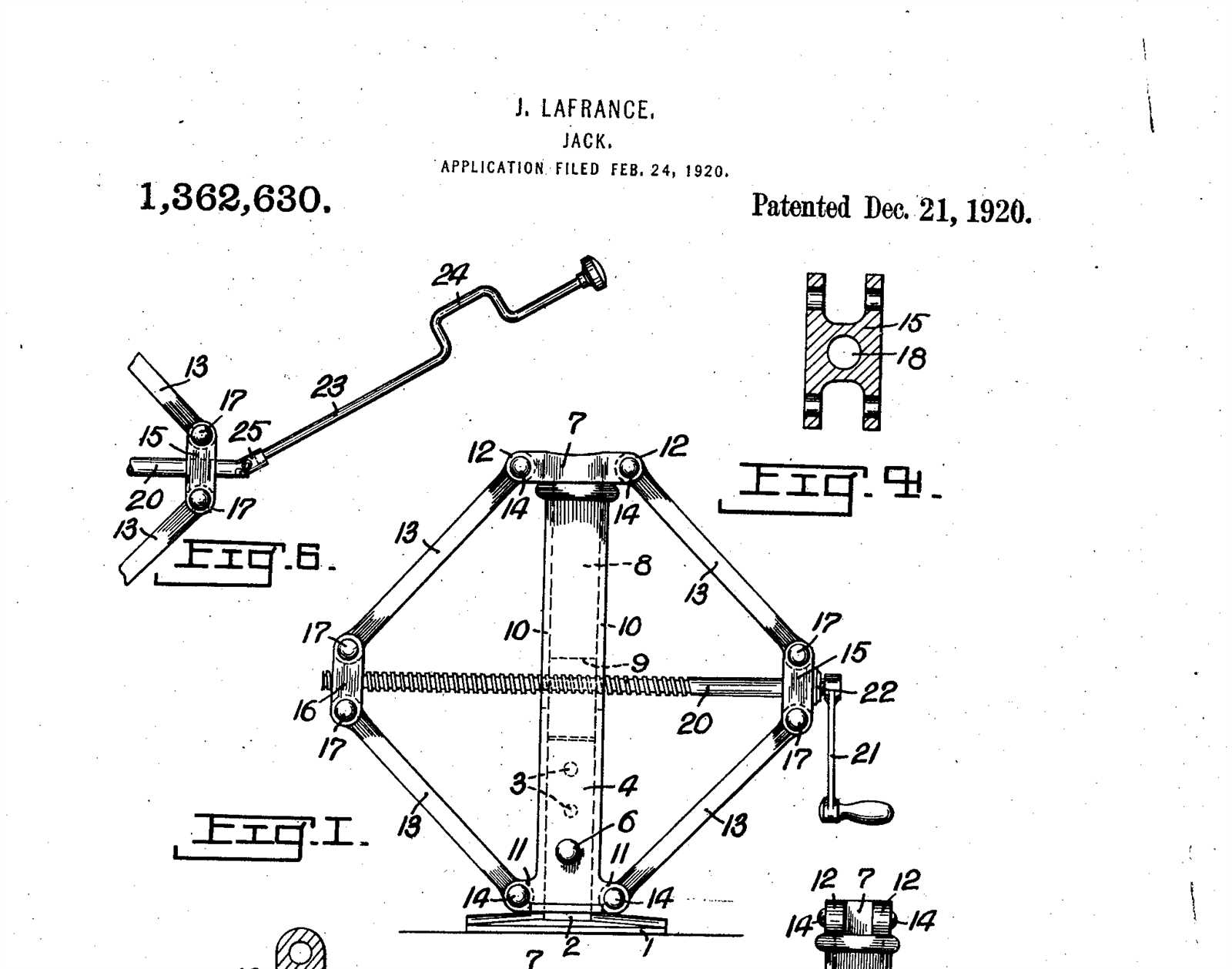

Car Jack Components and Their Functions

Understanding the different elements of lifting equipment is essential for ensuring smooth operation and efficient performance. Each component serves a specific function, and knowing how they work together is key to maximizing safety and functionality.

The following is a list of common elements found in such tools and their respective roles:

- Base Plate: Provides stability and support, ensuring the tool stays in position during use.

- Pump Handle: Used to manually operate the lifting mechanism, allowing the user to raise the load.

- Lifting Mechanism: The core system that transfers force from the pump handle to elevate the load.

- Release Valve: Controls the lowering of the load by releasing the pressure in the lifting mechanism.

- Handle Grip: Ensures comfort and better control during operation, helping the user maintain a firm hold.

- Support Arm: The part that directly connects to the load, facilitating the lifting process.

By becoming familiar with these key components, users can more effectively use the equipment, avoid damage, and troubleshoot potential issues as they arise.

How to Identify Each Car Jack Part

Recognizing the individual components of a lifting tool is essential for both effective operation and maintenance. Each element has a distinct shape, function, and location, making it easier to identify and understand its purpose.

Begin by examining the overall structure. Typically, the base provides stability, and the lifting mechanism will be positioned centrally, with moving parts clearly visible. The release valve is often near the top, where pressure can be adjusted. Handles are generally designed for ease of grip and movement, while support arms are located near the lifting surface.

Understanding the layout of the equipment helps users become more familiar with its components and ensures they are used correctly during lifting tasks. Proper identification is also important for maintenance or troubleshooting when necessary.

Step-by-Step Car Jack Assembly Guide

Assembling lifting equipment requires careful attention to detail to ensure everything functions correctly and safely. The process involves connecting various components in a specific order, making sure each part is securely fastened and aligned.

Follow these steps for successful assembly:

- Start with the base: Place the stabilizing plate on a flat surface to ensure stability during assembly.

- Attach the lifting mechanism: Position the main lifting components and secure them according to the guidelines.

- Install the pump handle: Connect the handle to the pump system, ensuring it moves freely and without obstruction.

- Connect the release valve: Attach the valve mechanism to the designated section and check for proper movement.

- Check alignment: Ensure all parts are correctly aligned and tightly secured before using the equipment.

Once the assembly is complete, verify the tool’s functionality by testing each part individually to ensure smooth operation. Regular checks after assembly are important to maintain safety and efficiency.