When it comes to maintaining the efficiency of an engine, understanding the various components of the fuel delivery system is crucial. These systems are responsible for mixing air and fuel, ensuring smooth operation. A visual guide of these parts can greatly assist in identifying and troubleshooting common issues that may arise over time.

By familiarizing yourself with the layout and function of each component, you can make informed decisions when it comes to repairs or adjustments. A clear understanding of how each part interacts can prevent unnecessary mistakes and improve the longevity of your engine.

With this guide, you will gain insight into how these mechanisms work together, allowing you to tackle maintenance tasks with confidence and precision. Recognizing the signs of wear and tear can save both time and money, making the overall process much more manageable.

Understanding Marvel Schebler Carburetor Components

Engine fuel systems consist of several key elements that work together to regulate the flow and mixture of air and fuel. Each component has a specific role, whether it’s controlling fuel delivery, ensuring proper air intake, or maintaining efficient combustion. Understanding how these parts interact is essential for proper maintenance and troubleshooting.

The fuel delivery mechanism relies on different components to provide the right amount of fuel at the right time. These elements must work in harmony, adjusting for changes in throttle, load, and environmental conditions. A detailed understanding of how each component functions helps in diagnosing problems and performing necessary repairs effectively.

Maintenance of these systems requires attention to detail, especially in identifying signs of wear or damage. Whether it’s cleaning or replacing worn-out elements, knowing the function of each part allows you to take the right steps to ensure the engine operates at peak performance. Understanding the system layout will save time and reduce the likelihood of costly mistakes during repairs.

How to Read a Carburetor Parts Diagram

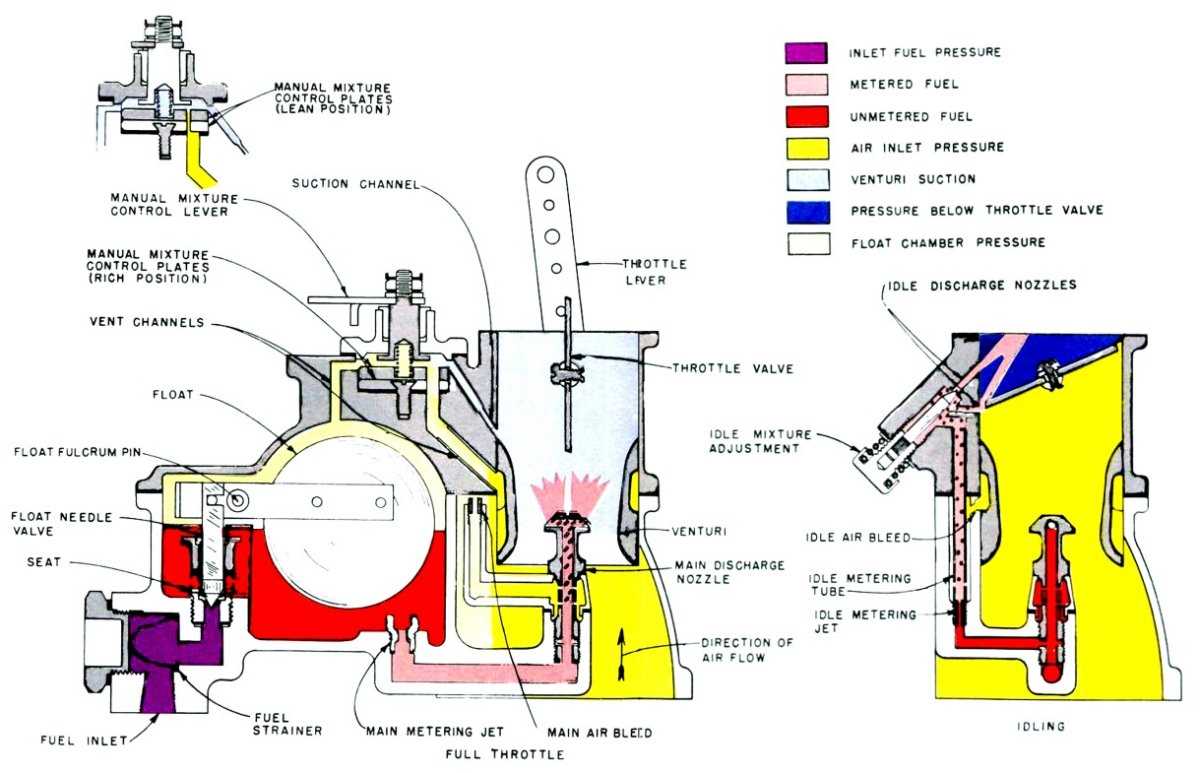

Interpreting a visual layout of the fuel system can be challenging, but understanding the key elements of the schematic makes it easier. These illustrations represent the positioning and function of each component, providing a roadmap for maintenance and repair. Recognizing the symbols and understanding their relationships is essential for diagnosing issues effectively.

Identifying Components and Their Functions

Each part of the system is labeled and shown in relation to others. For instance, you can identify the air intake elements, fuel flow pathways, and control mechanisms. Understanding what each part does allows you to pinpoint potential sources of malfunction, such as blockages or leaks. Familiarizing yourself with common component names will help you follow the diagram with ease.

Reading the Flow of Fuel and Air

Many diagrams include arrows to indicate the direction of fuel and air flow through the system. These arrows help visualize how the elements interact with one another during engine operation. By understanding the flow path, you can identify where problems like poor fuel mixing or insufficient air intake may arise, making it easier to address issues accurately.

Common Issues in Marvel Schebler Carburetors

Even the most well-designed fuel systems can experience issues over time due to wear, dirt accumulation, or improper maintenance. Identifying common problems early is key to ensuring smooth engine performance. Many of these issues stem from fuel delivery problems, air intake blockages, or malfunctioning control mechanisms.

Fuel starvation is one of the most common problems faced by these systems, often caused by clogged fuel lines or a dirty fuel filter. When fuel doesn’t reach the engine properly, it leads to poor performance or even stalling. Regular cleaning and inspection can help prevent such issues from arising.

Another frequent problem involves air intake obstructions, which can reduce the efficiency of the air-fuel mixture. Dust or debris entering the intake can create blockages, leading to engine hesitation or rough idling. Ensuring that the intake system is clean and free from debris is essential for maintaining optimal performance.