Proper knowledge of the inner workings of your outdoor power equipment is essential for efficient operation and maintenance. Whether you’re a hobbyist or a professional, knowing how each component fits together and functions will save you time and prevent unnecessary repairs.

By familiarizing yourself with the individual elements, you can quickly diagnose issues and make informed decisions when replacements are necessary. This comprehensive guide will help you identify key components, explain their roles, and show how to maintain them effectively.

Getting to know your tool’s structure not only improves performance but also extends the life of your equipment. With this information, you’ll be able to approach maintenance with confidence and avoid costly mistakes.

Understanding Your Outdoor Tool’s Components

To fully grasp how your power equipment functions, it is important to break down its core components. Each part plays a specific role, working together to ensure smooth operation and efficiency. Gaining an understanding of these elements allows you to maintain your tool properly and address issues as they arise.

Key Elements and Their Functions

The engine, drive system, and cutting mechanism are just a few of the integral components that contribute to the overall performance. The engine is responsible for providing power, while the drive system transmits this power to the moving parts. The cutting mechanism, typically consisting of a blade and related components, performs the actual work. Knowing how each part contributes to the entire process helps in diagnosing problems and making repairs when necessary.

Maintaining Your Tool’s Efficiency

Regular inspection and care of individual components will extend the lifespan of your equipment. Ensuring that all parts are clean, well-lubricated, and free from wear and tear is essential for preventing malfunctions. Familiarity with the key components will help you identify early signs of damage or performance issues, allowing for timely intervention and minimizing the need for costly repairs.

How to Use a Parts Breakdown

Understanding the layout of your tool’s components is crucial for effective maintenance and troubleshooting. A detailed breakdown helps you locate individual elements quickly, identify specific issues, and ensure you have the correct parts when performing repairs. This guide will show you how to navigate such a reference efficiently and how it can assist you in maintaining optimal performance.

Locating and Identifying Components

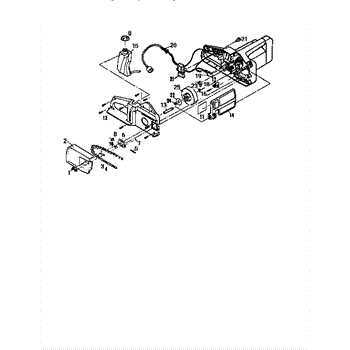

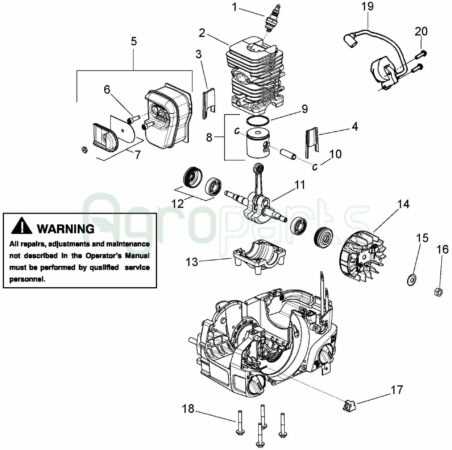

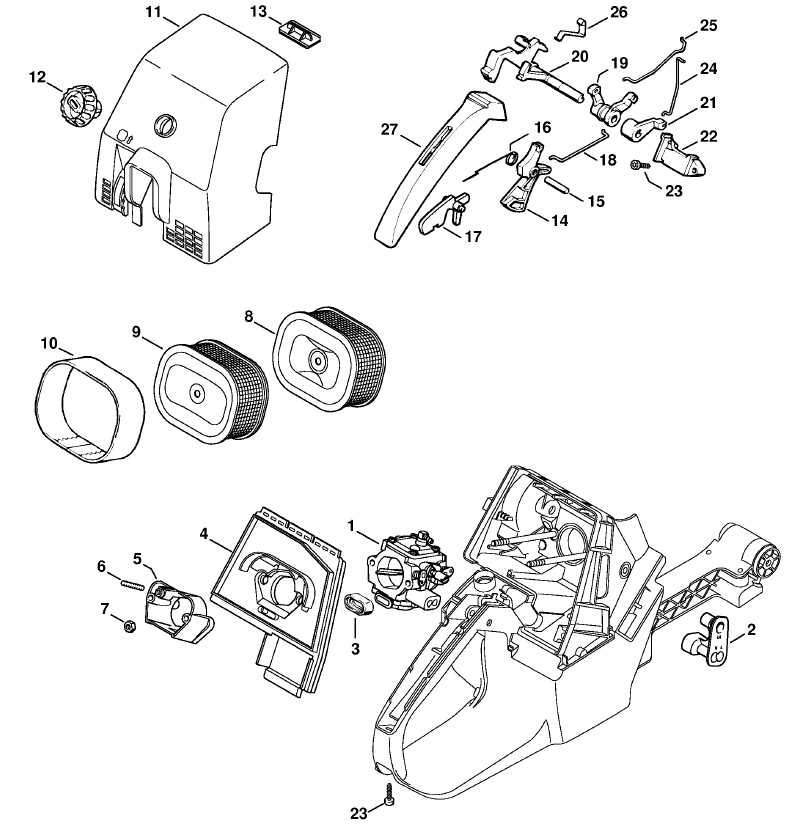

Start by identifying the various sections of your equipment. A well-organized illustration will group related parts together, making it easier to spot what you need. For instance, the engine section will feature the key elements responsible for powering the machine, while other sections will highlight the cutting mechanism or the drive system. Familiarizing yourself with the layout enables you to pinpoint any parts that might require attention.

Using the Diagram for Repairs and Replacements

Once you identify a malfunctioning part, refer to the breakdown for exact replacement options. Knowing the precise component number and specifications will help you find the right item quickly, avoiding errors in purchasing and installation. Additionally, understanding how each piece fits into the overall structure allows for easier assembly or disassembly during repairs.

Common Tool Maintenance Tips

Regular maintenance is essential to keep your outdoor power equipment running smoothly and to extend its lifespan. Proper care helps prevent breakdowns, ensures efficient performance, and reduces the need for expensive repairs. In this section, we’ll cover some of the most important maintenance practices you should follow to maintain your tool in optimal condition.

Keep the Engine Clean and Well-Lubricated

The engine is the heart of any power equipment, so it’s essential to ensure it remains clean and well-lubricated. Regularly check for any dirt or debris buildup around the engine, and use the appropriate cleaning methods. Additionally, make sure the engine oil is changed at the recommended intervals to maintain proper function and avoid overheating.

Inspect and Maintain the Cutting Mechanism

Proper care of the cutting mechanism is vital for efficient performance. Regularly check the blade for any signs of wear or damage, such as dullness or chips. Sharpen the blade when necessary, and ensure it’s properly aligned to ensure clean and precise cuts. Lubricate the cutting mechanism to reduce friction and extend its life.