When it comes to maintaining outdoor power equipment, understanding the internal structure is crucial. Each machine consists of numerous components that work in harmony to ensure optimal performance. Familiarity with these elements allows for more efficient repairs and better care, extending the lifespan of the tool.

By examining the various sections and how they interconnect, users can identify potential issues before they become major problems. Knowing the function of each piece helps in choosing the right replacement or upgrade, ensuring smoother operation during use.

Whether you are troubleshooting a malfunction or performing routine maintenance, a clear understanding of your tool’s build will empower you to tackle any challenge with confidence. This guide provides the necessary knowledge to keep your equipment running at its best.

Understanding Outdoor Power Tool Components

To fully grasp how a cutting tool operates, it’s important to understand the different elements that make up its structure. These components each have a unique function, contributing to the overall efficiency and effectiveness of the machine. Recognizing their role will help users optimize performance and troubleshoot issues more effectively.

The engine serves as the powerhouse, converting fuel into energy, while the clutch engages the drive system, allowing the user to control the tool’s motion. Other components, such as the bar and drive mechanism, are key in ensuring smooth operation during use, ensuring that power is properly transmitted to the cutting edge.

Understanding how each part interacts with the others allows for more precise maintenance and faster identification of wear or damage. By regularly inspecting and replacing worn components, users can significantly improve the tool’s lifespan and avoid unexpected failures during use.

How to Read a Power Tool Component Layout

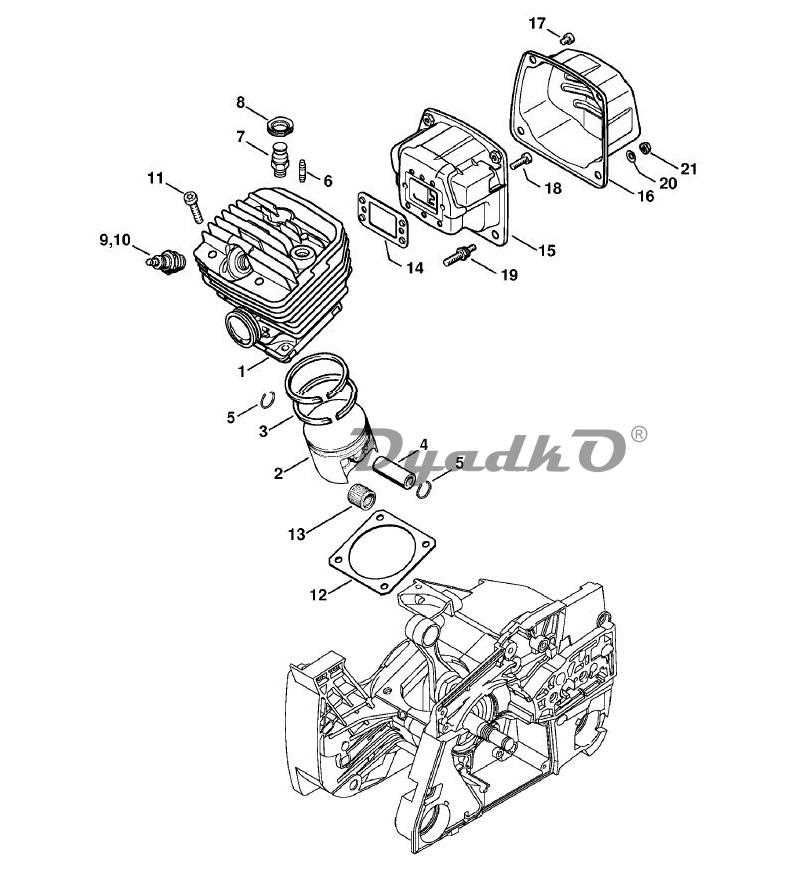

Interpreting the layout of a power tool’s internal components can seem challenging at first, but with the right approach, it becomes much easier. A well-organized schematic or illustration highlights the placement and function of each part, providing a clear guide for maintenance and repairs. Understanding how to read these layouts is an essential skill for anyone handling such equipment.

Start by identifying the main sections of the layout, such as the engine, drive system, and cutting mechanism. Each part will typically be labeled, and it’s important to match the labels with the components in your equipment. Follow the connections between elements to see how power flows and which parts interact with each other.

Once you are familiar with the overall structure, focus on specific components that may need attention. These diagrams often include numbered or color-coded sections to help pinpoint exact parts. By using the diagram as a reference, you can more accurately diagnose issues and find replacement parts when necessary.

Common Issues and Replacement Parts

Understanding the most frequent problems that arise in power tools is essential for effective maintenance. Many issues can be traced back to worn or damaged components, which, when replaced, can restore the machine’s functionality. Recognizing these signs early helps prevent more serious damage and extends the tool’s life.

Engine Failures and Solutions

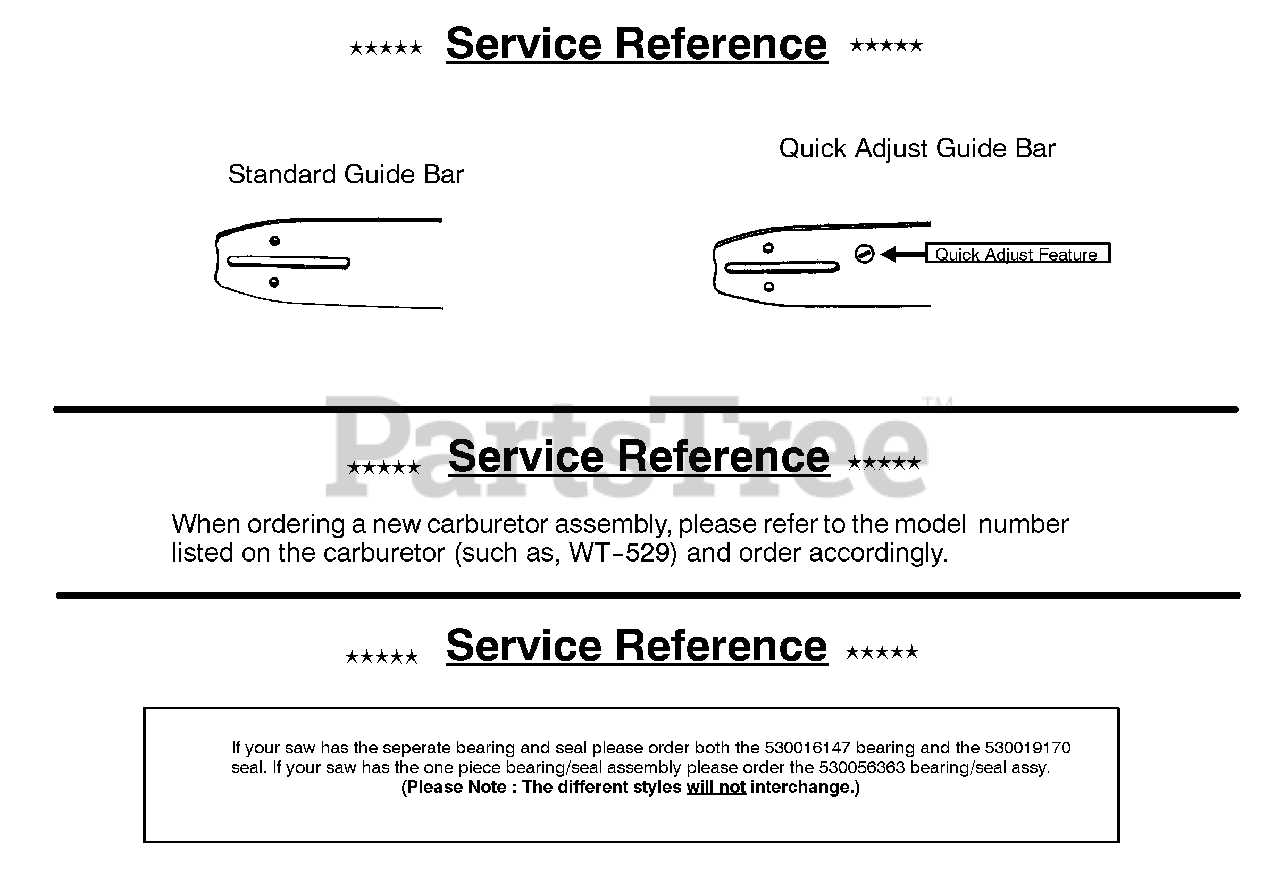

A common issue is engine malfunction, often due to fuel or ignition system problems. If the tool struggles to start or runs erratically, the spark plug, fuel filter, or carburetor may need attention. Replacing these components can improve performance and prevent further issues. Regular cleaning and maintenance are key to avoiding engine-related failures.

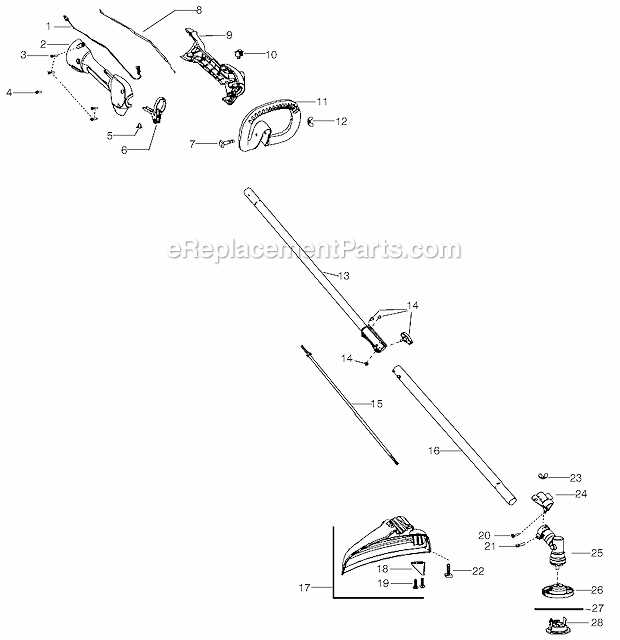

Drive System and Cutting Mechanism

Another frequent issue involves the drive system or cutting elements. Over time, wear on the chain or bar can cause reduced cutting efficiency. Replacing the chain, adjusting the tension, or swapping out the bar will restore the tool’s effectiveness. Ensuring that all moving parts are lubricated and properly aligned is essential for optimal performance.