For anyone working on vehicle maintenance or repairs, having a clear and detailed layout of the car’s internal structures is essential. These illustrations serve as invaluable guides for both novice and experienced mechanics, helping to identify parts quickly and accurately. The right representation can simplify diagnostics and make the repair process more efficient.

In this section, we’ll explore the importance of having a clear visual reference for the essential components of a pickup truck. This type of reference is particularly useful when dealing with complex systems that require careful attention to detail.

Knowing how each part fits into the larger structure ensures better decision-making when planning repairs or upgrades. Understanding the connections and placements can significantly reduce errors and improve overall functionality in vehicle servicing.

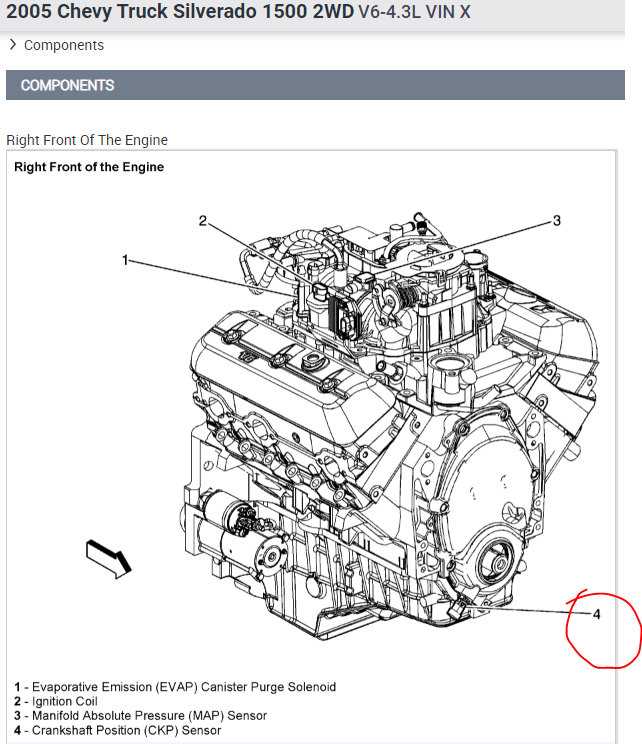

Understanding the 2005 Chevy Silverado Components

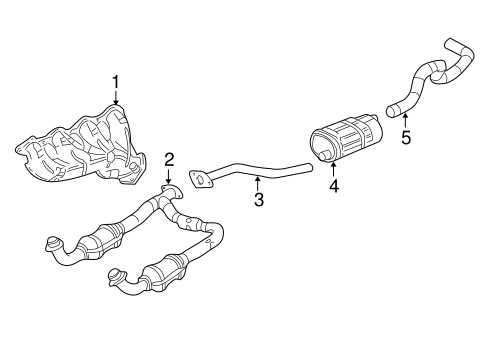

When it comes to vehicle maintenance and repair, understanding the structure and layout of key mechanical elements is crucial. Each system within a truck, from the engine to the electrical components, is interconnected. Properly identifying and understanding these parts helps ensure smooth operation and easier troubleshooting when something goes wrong.

For any truck owner or technician, knowing the specific locations and functions of each crucial element makes it simpler to identify issues, perform upgrades, and prevent potential breakdowns. By referencing detailed visual aids, one can map out the essential systems that keep the vehicle running efficiently.

Familiarity with the system components also allows for better planning when servicing or replacing damaged parts. Understanding how everything works together makes it easier to make informed decisions, ultimately reducing the risk of unnecessary repairs and improving vehicle longevity.

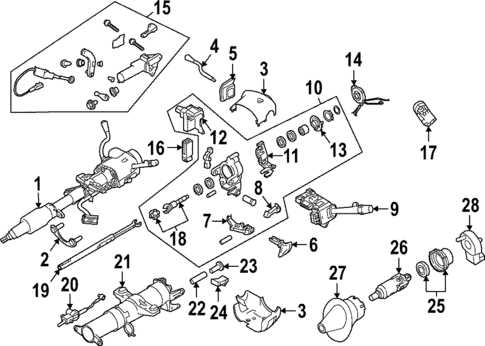

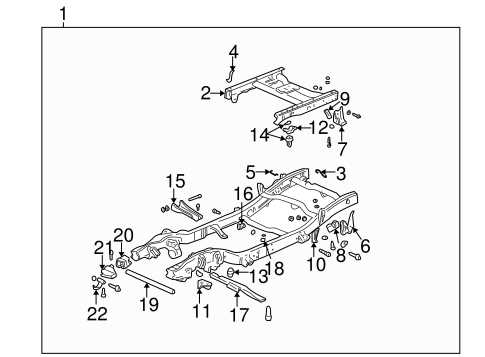

Visual Breakdown of Essential Vehicle Parts

Having a clear visual representation of a vehicle’s internal components allows for easier identification and maintenance of key elements. This approach ensures that each individual system can be examined with precision, aiding in both diagnosis and repair tasks. Whether you’re working on the engine, transmission, or electrical system, understanding where each part fits within the overall structure is vital for efficiency.

Engine and Transmission Systems

The engine and transmission form the heart of the vehicle’s performance. Understanding how these components interact helps in troubleshooting issues related to power delivery, fuel efficiency, and overall mechanical function. From the engine block to the transmission housing, knowing their locations and functions is essential for smooth operation.

Electrical and Control Systems

The electrical network plays a significant role in vehicle operation, handling everything from lighting to the fuel injection system. Knowing the key connections and control modules that govern these systems provides valuable insight into diagnosing electrical malfunctions and upgrading essential components for enhanced performance.

How to Use the Parts Diagram Effectively

Using a visual reference guide efficiently can greatly improve your understanding of a vehicle’s structure and assist in identifying areas that need attention. These guides provide a clear map of the vehicle’s internal systems, making it easier to pinpoint parts that may need repair or replacement. Knowing how to interpret this information allows for faster troubleshooting and more accurate maintenance.

To make the most of such a reference, it’s important to familiarize yourself with the layout and the function of each highlighted component. Start by locating the system you’re working with and cross-reference it with the overall schematic. This will give you a clear understanding of how parts interact with one another.

Additionally, ensure that you follow a logical process when identifying components. Begin with the major systems and work your way down to more specific areas. This method not only helps avoid confusion but also improves the efficiency of the diagnostic and repair process.