Every mechanical device, especially those designed for heavy outdoor use, relies on a variety of individual elements working in harmony. Understanding how each part contributes to the overall function is crucial for efficient maintenance and repair. For tool owners, knowing the structure and components can prevent common issues and extend the lifespan of the equipment.

Identifying individual parts and their purpose is essential when performing any maintenance. This knowledge allows for quick identification of issues and helps in sourcing the right replacement when necessary. Without an in-depth understanding of the assembly, diagnosing faults can become a challenging task.

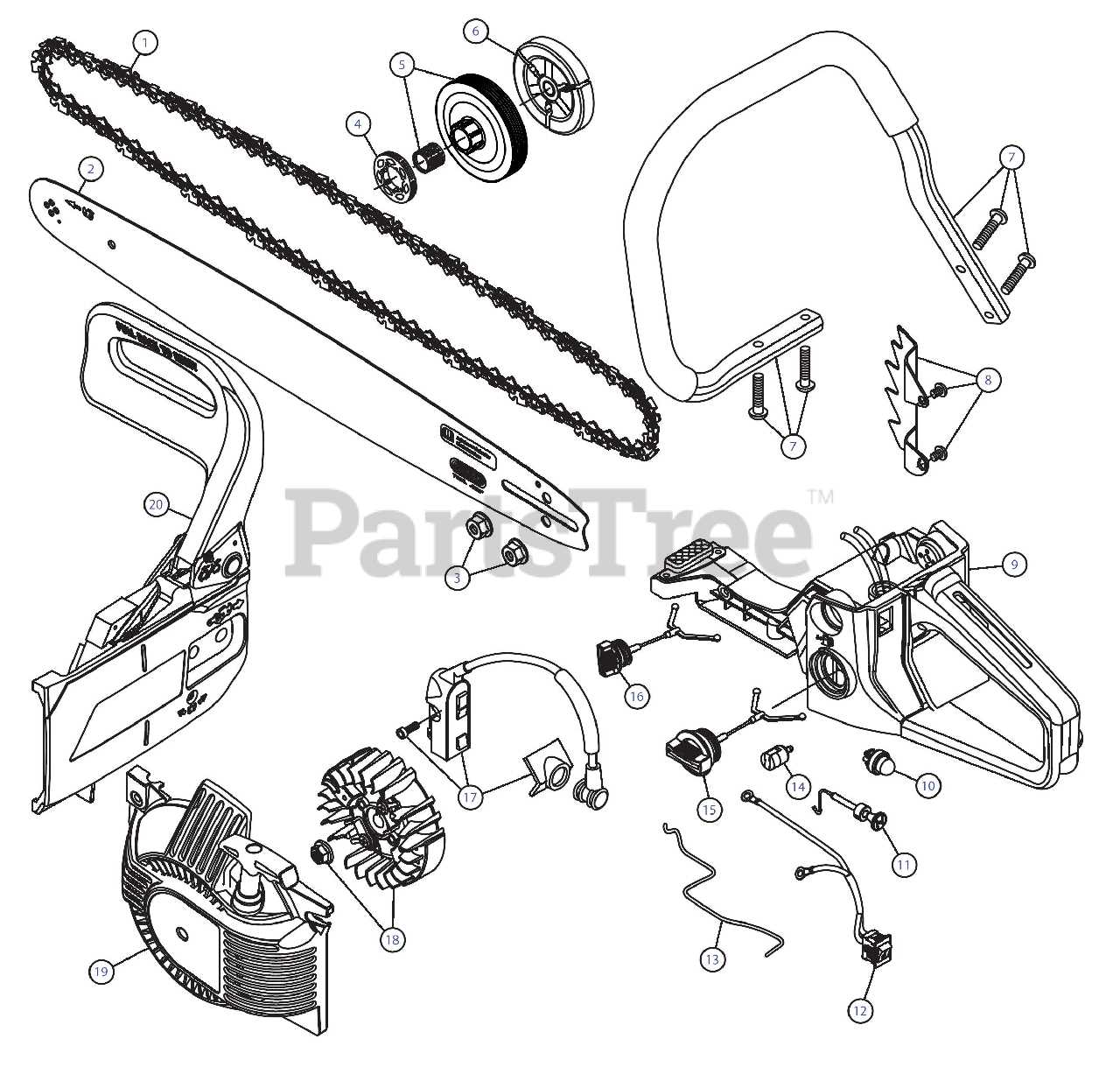

Having access to a detailed visual representation of the components of your tool can make the repair process much easier. It provides clarity, ensuring that even less experienced users can effectively identify and replace damaged or worn-out parts. With this guide, you will gain valuable insight into the essential components of your outdoor power equipment and learn how to keep it running smoothly.

Understanding Craftsman 16 36cc Chainsaw Components

Proper functioning of outdoor power tools relies on a variety of carefully engineered components, each contributing to the tool’s overall performance. A tool like this consists of essential elements that work together to ensure effective operation. Understanding these components not only improves the user’s ability to handle maintenance tasks but also enhances safety and efficiency during use.

Key Elements of the Tool’s Assembly

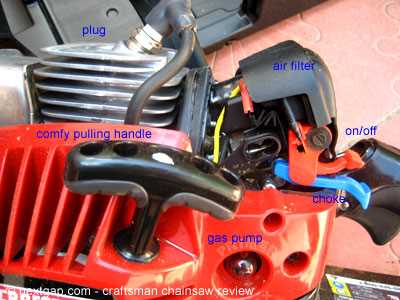

The engine serves as the heart of the machine, converting fuel into mechanical energy to drive the various components. Key parts like the air filter and fuel system play a crucial role in ensuring proper engine performance. The ignition system, including the spark plug, is responsible for firing the engine at the right moments, allowing for smooth operation.

Ensuring Longevity with Regular Maintenance

Keeping the tool in top working condition involves regular checks and timely replacements of worn components. Chain tension and lubrication are vital for preventing unnecessary wear on moving parts, while the clutch helps engage the drive mechanism when needed. Understanding how to adjust and replace these elements as part of routine maintenance can significantly prolong the tool’s lifespan.

How to Read a Chainsaw Parts Diagram

Understanding the layout and structure of a tool can be much easier when presented in a visual format. A detailed illustration can help users identify components, their locations, and how they interact within the entire mechanism. Learning how to interpret these images is essential for troubleshooting, repairs, and regular upkeep of the equipment.

Decoding the Symbols and Labels

Most visual guides use simple symbols and clear labels to identify each component. Pay attention to numbered references or color-coded sections that point to specific parts. These guides often include a legend that explains the meaning behind each symbol, making it easy to match parts with their corresponding descriptions. This helps users avoid confusion when locating or replacing parts.

Understanding the Assembly Flow

The parts are usually displayed in a way that follows the assembly order. This method helps users understand how each part fits into the whole machine. The visual representation shows how different components connect to each other, giving a better idea of how a malfunction in one area may affect other elements. This understanding is crucial for both repair and preventative maintenance.

Common Replacement Parts for Craftsman Chainsaws

Like any piece of machinery, regular use will eventually lead to wear and tear on various components. Understanding which parts are most susceptible to damage allows users to proactively replace them before they cause bigger issues. By addressing these common replacements, the tool can maintain optimal performance and extend its service life.

Essential Wearable Components

The guide bar and chain are among the most frequently replaced components, as they endure the most stress during operation. Over time, the teeth on the chain can become dull, while the guide bar can develop grooves, reducing efficiency and cutting precision. Regularly replacing these ensures smooth operation and safe usage.

Engine-Related Components

For the engine to perform at its best, certain components like the spark plug and air filter should be replaced periodically. The spark plug ensures proper ignition, while the air filter prevents debris from entering the engine, ensuring it runs cleanly. These small parts play a large role in keeping the engine running smoothly.