When it comes to maintaining and repairing outdoor power tools, having a clear understanding of the individual components is essential for efficient operation. Whether you are a seasoned user or just getting started, knowing the functions and connections of each element ensures smooth performance and longevity.

The intricate network of mechanical pieces and their specific roles within your equipment may seem complex at first. However, breaking down the design into manageable sections allows for easier identification, troubleshooting, and replacement. With the right knowledge, you can confidently handle repairs and upgrades without unnecessary confusion.

By familiarizing yourself with the construction of your tool, you are also taking a step towards more cost-effective and reliable maintenance. Understanding how the parts interact with each other is crucial for preventing damage and maximizing the tool’s efficiency in the long run.

Understanding Your Power Tool Components

Every outdoor power tool is made up of several key components that work together to ensure optimal performance. A thorough understanding of these elements is crucial for anyone who operates these tools regularly. Recognizing each component’s function and how it contributes to the overall efficiency will allow users to troubleshoot issues more effectively and carry out necessary repairs.

The various elements of the tool, from the engine to the cutting mechanism, all play distinct roles in the machine’s operation. Some components directly affect power delivery, while others ensure safe and smooth functioning. Learning the layout and relationship between these parts makes it easier to spot signs of wear or failure and take appropriate action.

Moreover, understanding these individual parts empowers users to perform routine maintenance and make informed decisions when purchasing replacements. Whether it’s replacing worn-out pieces or upgrading specific elements for better performance, having a clear grasp of how everything fits together will ensure that the tool continues to operate at its best.

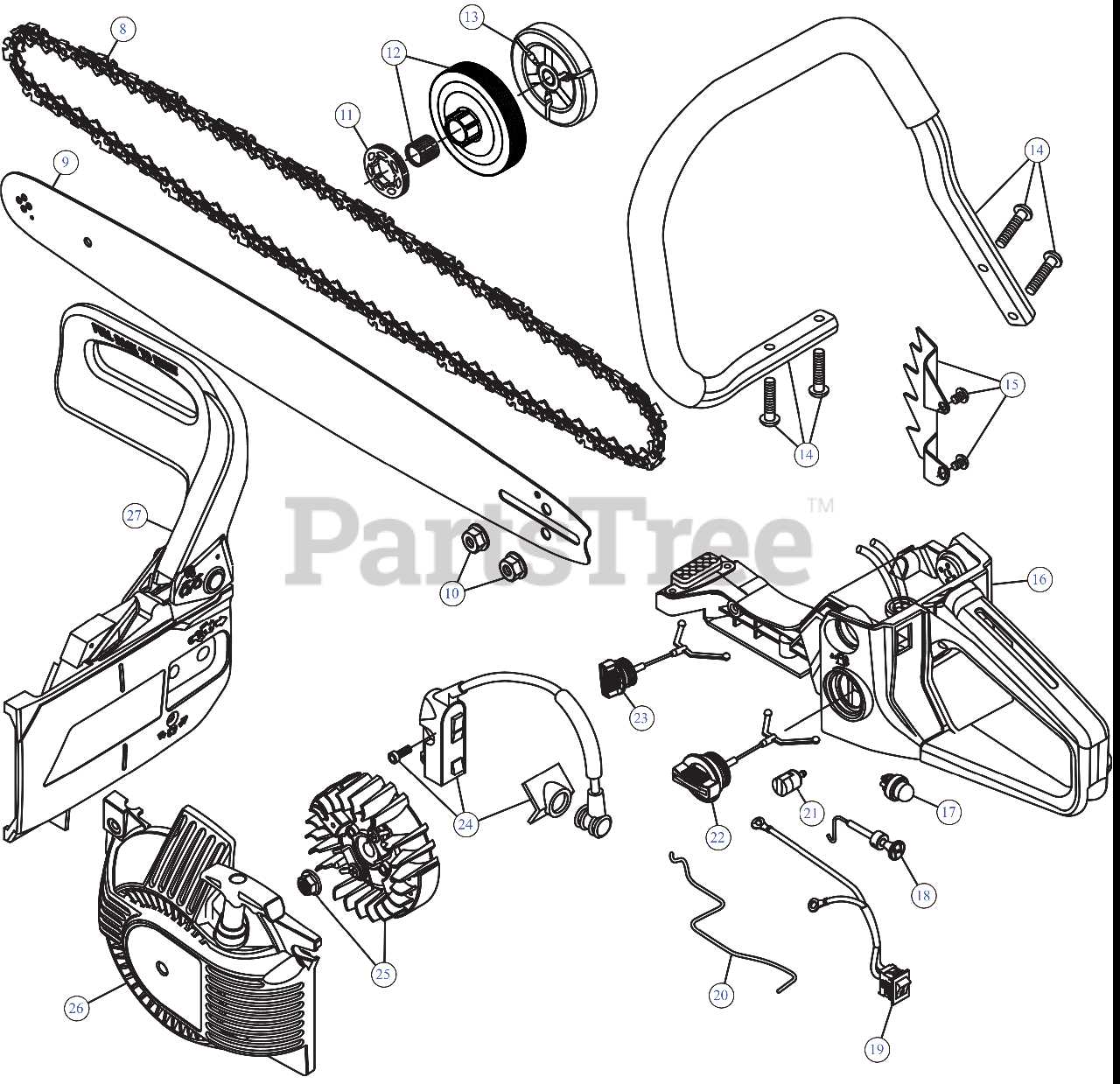

Identifying Key Components of the Tool

To operate any power tool effectively, it’s essential to know the primary components that drive its function. These components are designed to work in harmony to provide power, control, and safety during use. Identifying these elements can help troubleshoot issues, perform maintenance, and ensure smooth operation for every task.

Essential Components

- Engine – The engine is the heart of the tool, providing the power needed for operation. It converts fuel or energy into mechanical movement, driving other components.

- Drive Mechanism – This system transfers power from the engine to the operational parts, ensuring that the tool moves or cuts as intended.

- Handle and Grip – A key component for user control, ensuring a secure and comfortable hold, especially during extended use.

- Safety Features – These parts, such as the safety brake, ensure the tool can be used without unnecessary risk, reducing the chances of injury.

Understanding the Cutting Mechanism

- Guide Bar – This part supports and guides the cutting tool, helping it stay aligned while cutting through materials.

- Cutting Teeth – These sharp elements are responsible for slicing through wood or other materials with precision and efficiency.

- Chain Tensioner – This component keeps the cutting chain properly tightened, which is crucial for optimal performance and safety.

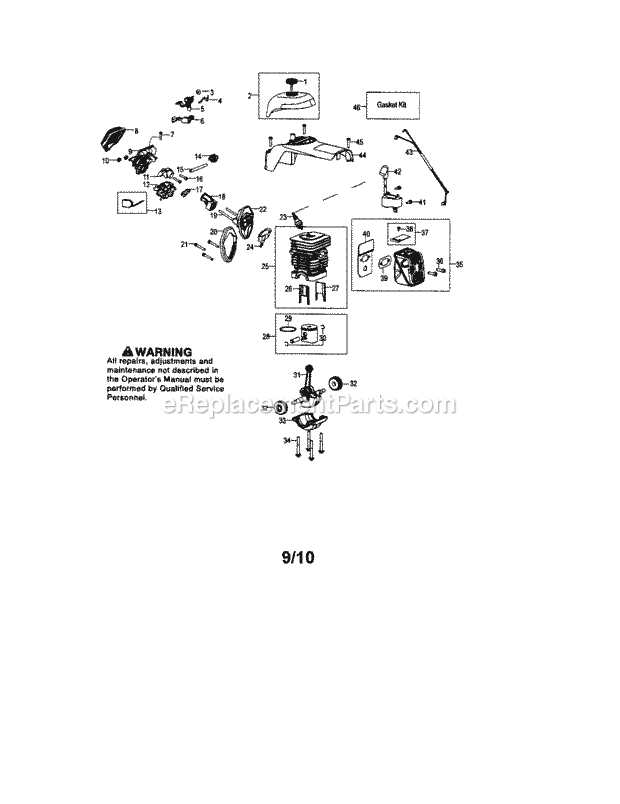

How to Maintain Your Power Tool Properly

Proper maintenance is essential for ensuring the longevity and performance of any power tool. Regular upkeep not only prevents breakdowns but also enhances safety and efficiency during use. By following a few simple steps, you can keep your equipment running smoothly and avoid costly repairs.

One of the most important aspects of tool maintenance is regularly checking the engine and mechanical components for any signs of wear or damage. This includes inspecting the fuel system, air filter, and spark plug. Ensuring these parts are clean and functioning properly will prevent performance issues and improve the tool’s power delivery.

Another key maintenance task is to keep the cutting mechanism in optimal condition. This involves checking the tension of the chain, sharpening the cutting teeth, and ensuring the guide bar remains aligned. Lubricating moving parts will also help reduce friction and prevent overheating during extended use.

Additionally, regularly cleaning the tool after each use is crucial. Dirt, debris, and resin buildup can affect the performance of various components. Use a soft brush or cloth to remove any buildup, paying close attention to the ventilation areas and safety features. Store the tool in a dry, secure location to prevent rust and other environmental damage.