When it comes to maintaining and repairing your equipment, understanding its internal structure is key. Knowing where each element fits and how they interact ensures that any issue can be swiftly addressed without unnecessary delays. This knowledge is especially valuable for efficient operation and longevity.

In this guide, we will explore the visual representation of key components, offering a clearer understanding of their function. By becoming familiar with the layout and connections, you can identify problems faster and make more informed decisions regarding maintenance or replacement.

From the core functions to the intricate details, having a clear overview of all the essential elements can save time and effort in the long run. A solid grasp of your equipment’s configuration empowers you to keep it running at optimal levels.

Understanding Craftsman 3000i Parts

Each machine is made up of various components that work together to ensure smooth functionality. Recognizing the role of each piece is vital for both troubleshooting and regular upkeep. Understanding the layout and connections between these elements allows for better maintenance and quicker identification of any malfunctions.

Key Components of Your Equipment

At the core of any mechanical system, several primary elements play crucial roles in operation. From the engine to the electrical system, each section must be in optimal condition to function effectively. Regular checks and a clear understanding of how these parts work in tandem will keep the machine running smoothly.

How to Identify and Replace Faulty Components

When issues arise, pinpointing the specific malfunctioning component can often be a challenge. By becoming familiar with the key sections and how they interconnect, identifying the problem becomes more straightforward. Knowing where each element is located and how to replace or repair it ensures minimal downtime and maximum performance.

How to Read the Generator Diagram

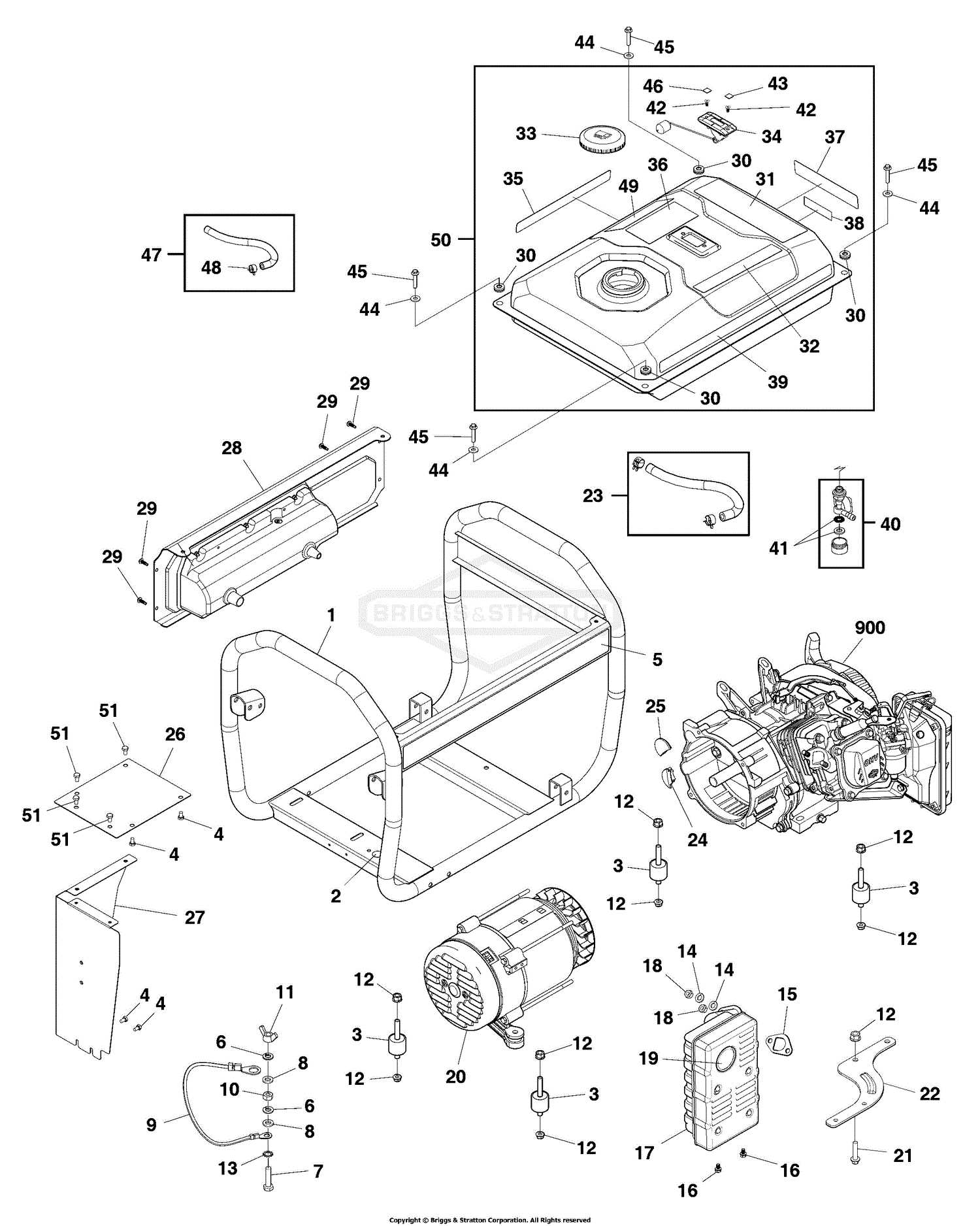

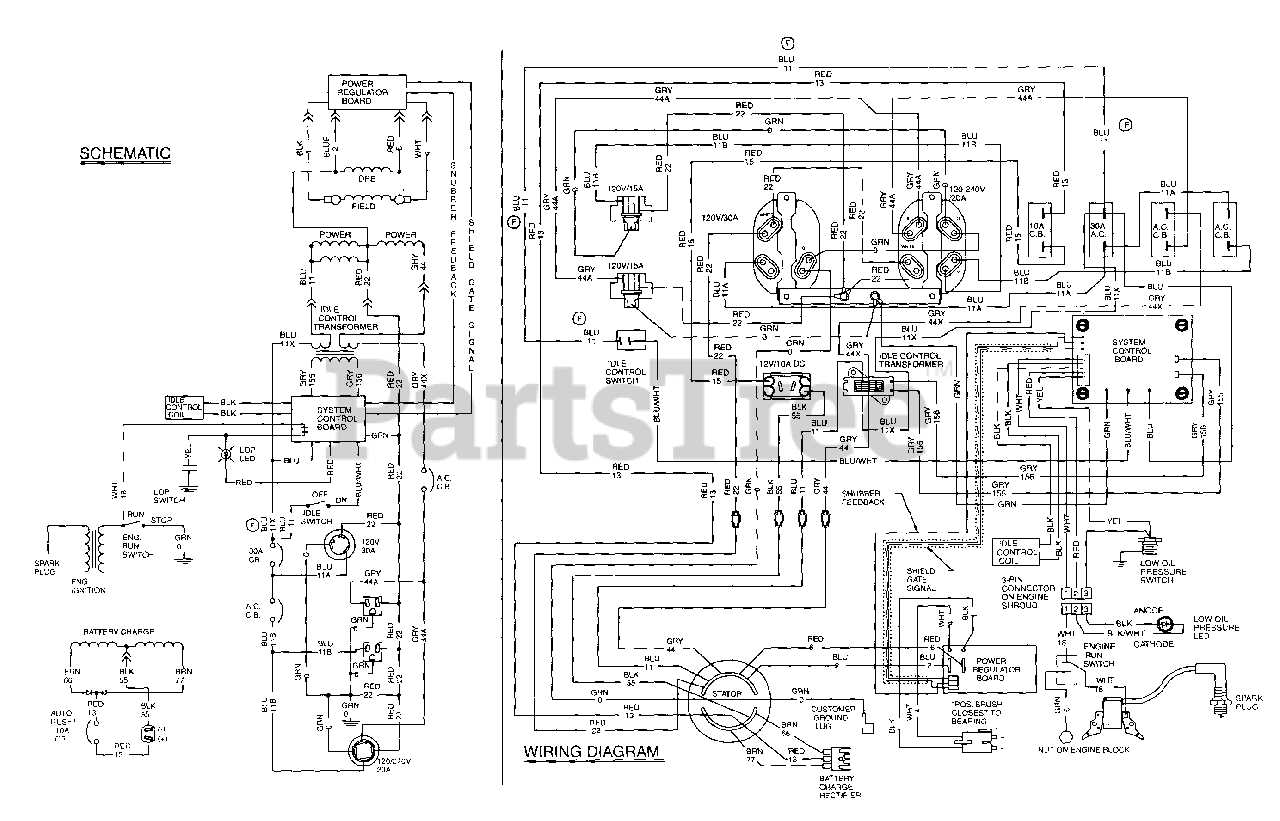

Understanding the layout of any machine is essential for proper maintenance and repair. A schematic can provide a detailed view of how each component is positioned and interconnected, offering invaluable insight into the system’s functioning. Knowing how to interpret these illustrations can help you quickly locate and fix issues without unnecessary complications.

Decoding the Symbols and Labels

The first step in understanding any visual representation is recognizing the symbols and labels used. These usually correspond to different components and connections within the system. Pay attention to the legends or key provided, as these will guide you in matching each symbol to its respective part.

Following the Flow and Connections

Once you understand the symbols, focus on how the components are connected. These connections represent the flow of energy or mechanical motion throughout the system. Tracing these links can help you identify where the issue lies, enabling faster troubleshooting and more efficient repairs.

Essential Components of the Craftsman 3000i

Every machine is made up of several core components that play critical roles in ensuring smooth operation. From the engine to the electrical elements, each part is necessary for efficient functioning. Understanding these key components and their interaction helps in effective troubleshooting and maintenance, enabling you to keep the equipment in optimal condition.

The main elements typically include the engine, fuel system, control panel, and exhaust system. Each has a specific function that contributes to the overall performance of the system. By familiarizing yourself with these components, you can better address issues as they arise and ensure the machine operates at its best.