Maintaining a tool in top condition requires knowledge of its individual components and how they interact. This guide will help you understand the structure and assembly of a 4-cycle engine model, ensuring smooth operation and easy maintenance. By examining the essential pieces of your device, you’ll be able to troubleshoot issues and replace parts with ease when needed.

Key Elements to Know

Familiarizing yourself with the major components is the first step in effective maintenance. Below are the core pieces that make up your device:

- Engine Housing: The main body that houses the motor and essential parts.

- Fuel System: Includes the fuel tank, filter, and lines that supply power to the engine.

- Drive Mechanism: Transfers energy from the engine to the moving parts.

- Control Handles: Allow you to operate and maneuver the device with ease.

How to Identify the Components

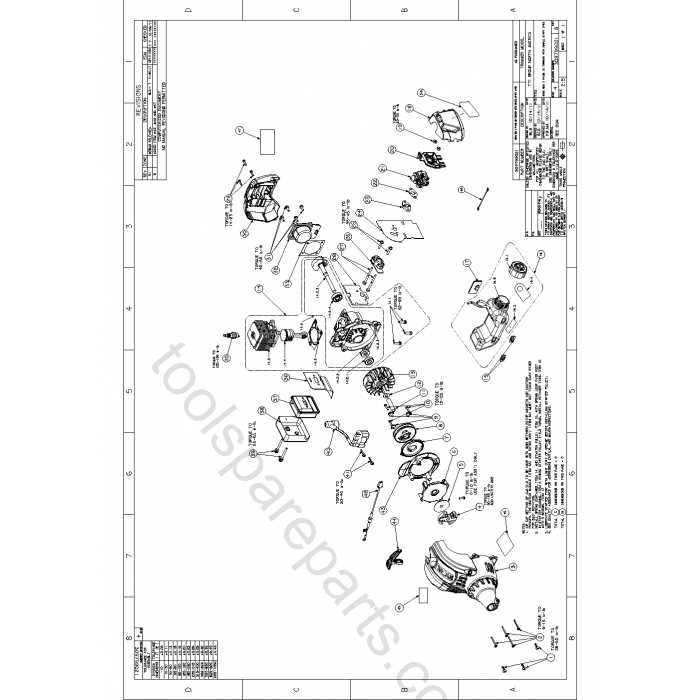

Understanding each part is crucial to troubleshooting. Start by examining the labels or serial numbers on your device, as they often contain useful information. Take note of the following:

- Model number for specific guidelines

- Part markings to assist with locating replacements

- Manufacturer’s guide for specific instructions

Replacing and Repairing Parts

When a part becomes worn or broken, knowing how to replace it correctly can save time and money. Follow these steps:

- Turn off the device: Always ensure it’s powered off before attempting any repairs.

- Locate the damaged part: Refer to your model’s manual or parts reference to find the affected area.

- Remove and replace: Use the proper tools to remove the damaged component and install the new one securely.

Maintaining the proper functioning of your tool will extend its lifespan, increase safety, and provide a smoother experience when in use. Regular inspection and knowledge of the system ensure you can perform repairs without unnecessary complications.

Tool Maintenance Guide

Identifying Essential Components

How to Interpret the Component Layout

Understanding the System Assembly

Replacing Key Elements in Your Tool

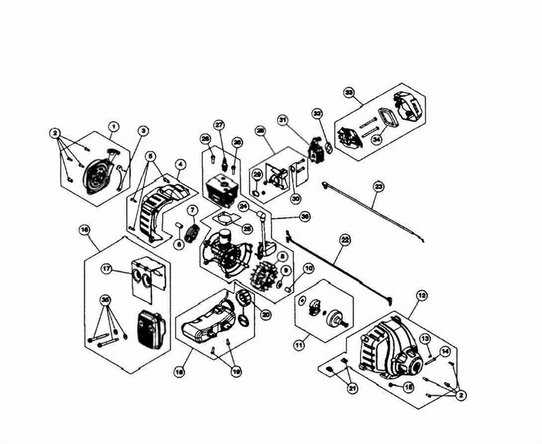

When working with any mechanical tool, understanding the structure and individual elements is vital for efficient use and maintenance. Knowing how each component functions and how to read the provided layout will ensure smooth operation and simplify the process of repairs or replacements. This section breaks down the important steps in managing your tool’s upkeep.

Identifying Essential Components

Every tool consists of specific parts that work together to enable functionality. By recognizing the critical pieces of your device, you can quickly troubleshoot problems and ensure longevity. Pay attention to these key components:

- Motor Housing: Encloses the engine and motor system, essential for operation.

- Fuel System: Comprising the tank, filter, and lines, this part delivers the necessary energy to the engine.

- Drive System: Transfers power from the engine to the working parts.

- Control Handles: The main interface used to steer and direct the machine during use.

How to Interpret the Component Layout

Reading the provided layout is a simple but essential skill. These schematics outline the positioning of each part, which is especially helpful when you need to replace or repair a component. The layout typically includes:

- Part numbers for identification

- Illustrations showing the arrangement of components

- Connections between various systems

Knowing how to interpret this guide allows for faster repairs, easier assembly, and better understanding of the device as a whole.

Replacing Key Elements

Occasionally, parts wear out or break, necessitating replacement. Here’s how to handle the process:

- Power Down: Always turn off and disconnect power before replacing parts.

- Locate the Faulty Component: Refer to the layout to pinpoint the malfunctioning part.

- Install the New Part: Use appropriate tools to carefully remove the damaged component and install the replacement.

By mastering these steps, you ensure the tool functions properly and remains in service for a longer period.