When it comes to maintaining and repairing outdoor power equipment, having a clear understanding of its components is essential. Identifying individual parts and knowing their functions can make a significant difference when performing repairs or replacements. Whether you’re a seasoned professional or a beginner, a detailed guide to your machine’s structure can simplify the process and ensure efficiency in your work.

Knowing the layout of each piece within the tool allows for quicker diagnostics, smoother repairs, and fewer mistakes. This knowledge is especially valuable when facing common issues or attempting to replace a worn-out component.

By using a visual reference, you can break down complex repair tasks into manageable steps, ensuring that you approach each part with the right tools and techniques. In this guide, we’ll explore the different elements of your tool, providing you with all the necessary information to keep it running smoothly.

Understanding the Craftsman 42cc Chainsaw Components

To keep your outdoor tool in top condition, it’s crucial to understand the key elements that make up its design. Each component plays a specific role in the overall function and performance. A deep understanding of these elements helps in diagnosing problems and ensures that maintenance tasks are performed with precision.

Major Elements of the Equipment

The assembly of your tool consists of several interconnected parts, each designed for a particular function. From the engine to the cutting mechanism, each section contributes to the tool’s overall efficiency. Knowing how these parts interact can help you manage repairs and maintenance tasks more effectively.

| Component | Function |

|---|---|

| Engine | Power source that drives the tool’s mechanism |

| Fuel System | Delivers the necessary fuel to the engine for operation |

| Cutting Mechanism | Responsible for cutting through materials with precision |

| Starter System | Facilitates the tool’s ignition for easy startup |

How Each Component Affects Performance

Understanding how each part works together is key to enhancing the overall performance. For example, if the engine is malfunctioning, it will affect the power output, making it difficult to cut through tougher materials. Similarly, issues in the fuel system can lead to improper fuel delivery, causing operational inefficiency. Regularly inspecting these components ensures the tool operates at peak performance, extending its lifespan and improving your work quality.

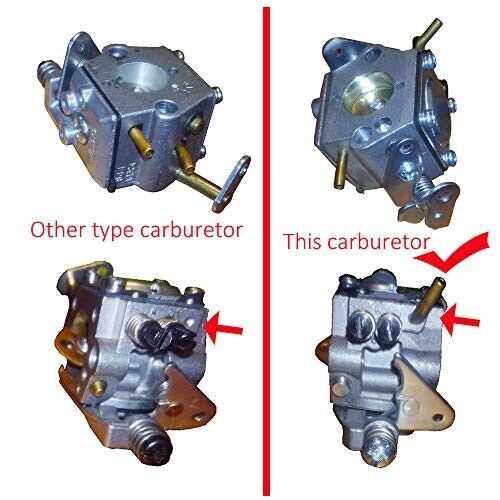

Identifying Key Parts for Repairs

When it comes to repairing your outdoor tool, knowing which components are essential for proper functionality is vital. Recognizing these crucial sections allows you to target specific issues, reducing repair time and ensuring that each part is properly maintained or replaced when necessary.

Every tool is made up of various key components, and each serves a specific purpose in maintaining its overall performance. From the ignition system to the cutting mechanism, understanding how these parts interact can help you diagnose problems quickly and ensure that you’re addressing the right areas when performing repairs.

Properly identifying which parts need attention helps prevent unnecessary replacements and minimizes the risk of further damage. Whether you’re facing a power issue, difficulty with cutting performance, or a malfunctioning starter, a clear understanding of the tool’s components is the first step toward effective repairs.

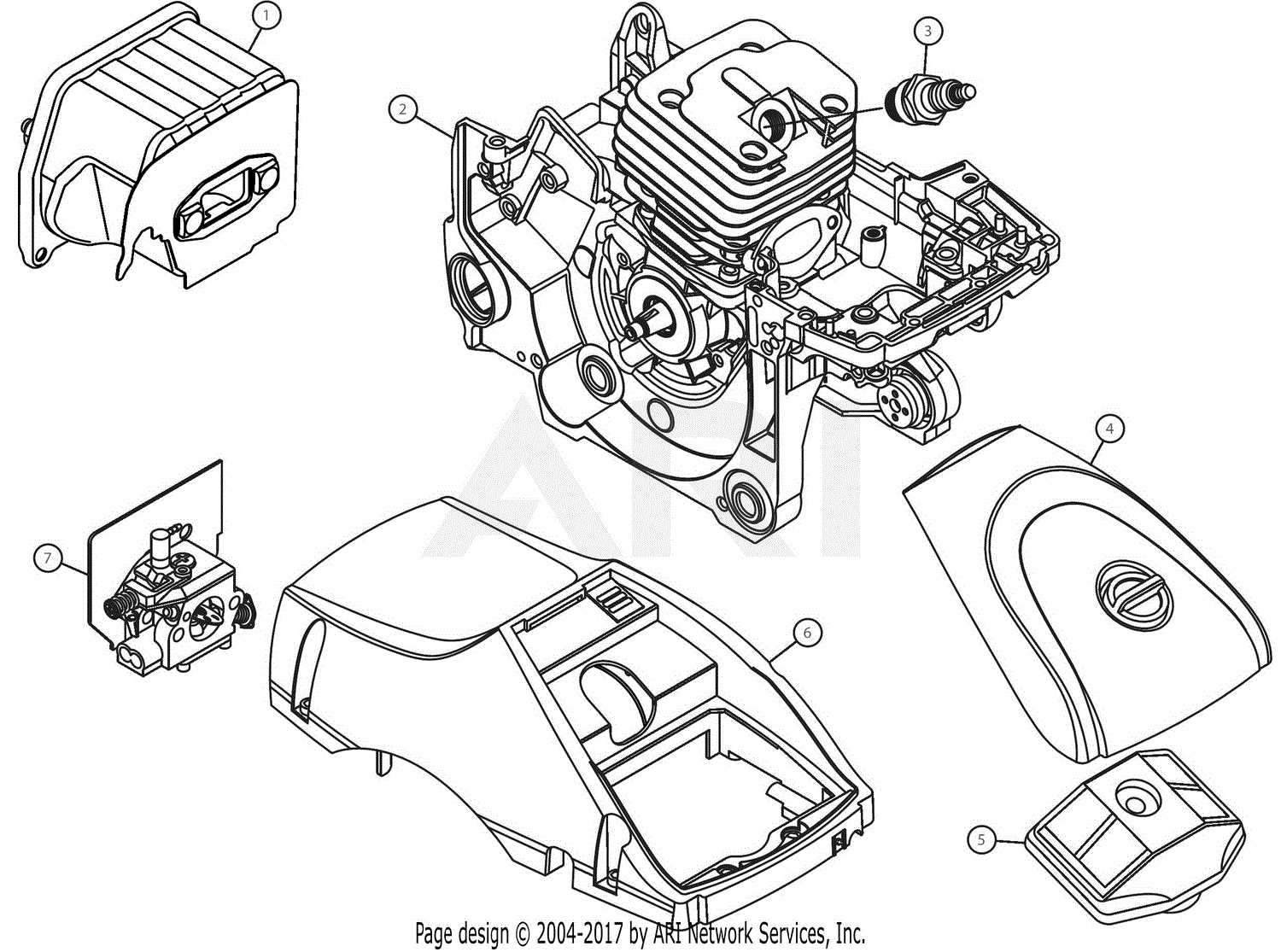

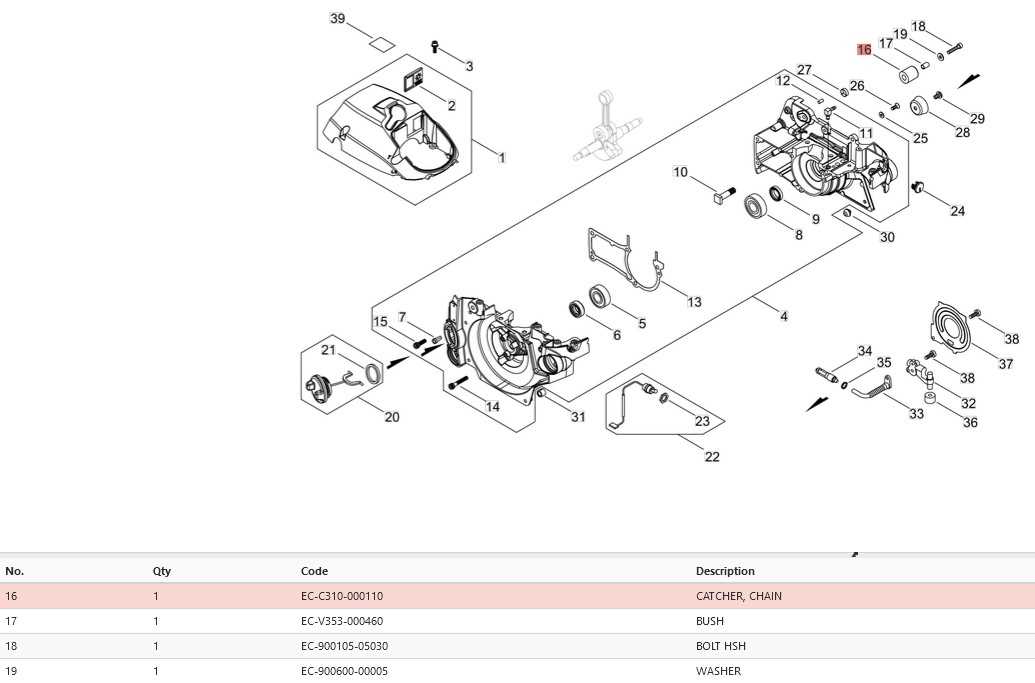

How to Use the Parts Diagram

Understanding how to read a visual reference of your tool’s components can significantly improve your repair and maintenance process. These visual guides provide a clear overview of how each section fits together, helping you locate specific components, troubleshoot issues, and replace worn-out parts with ease.

Step-by-Step Approach to Using the Guide

To make the most of this visual resource, begin by familiarizing yourself with the layout of the tool’s assembly. Identify each section in the guide and match it to the corresponding part on your tool. By following this step-by-step approach, you can pinpoint the areas that require attention or replacement, which helps streamline the repair process.

Tips for Efficient Use

Take note of key indicators such as part numbers or labels on the diagram, which can help you find replacements more quickly. Having a clear understanding of the tool’s components will also allow you to perform routine checks and catch potential issues early, preventing costly repairs down the line.

Step-by-Step Guide to Assembly

Assembling your outdoor tool correctly is crucial for its optimal performance. Following a clear, methodical process ensures that each component is placed in the correct position, preventing malfunctions and enhancing the tool’s longevity. A detailed guide can help you avoid mistakes during the setup and ensure a smooth operation once it’s fully assembled.

Start by gathering all the necessary components and tools required for assembly. Familiarize yourself with the manual or reference materials to ensure you are aware of each part’s role and placement. By following the sequence provided, you’ll ensure that the tool is set up efficiently and correctly, with all elements securely connected.

Make sure to double-check each step before moving on to the next one. This attention to detail will help you identify any potential issues early in the process and allow for easy troubleshooting if something doesn’t fit or function as expected. With patience and careful assembly, you’ll have your tool ready for use in no time.

Troubleshooting Common Chainsaw Issues

When your outdoor tool isn’t functioning properly, identifying the root cause can be challenging. Many common problems can arise, ranging from power failure to issues with cutting efficiency. Understanding how to troubleshoot these issues is essential for a quick fix and to avoid unnecessary repairs or replacements.

Common Issues and Possible Causes

Below are a few typical problems that users may encounter, along with their potential causes:

- Tool not starting – This could be due to a faulty ignition system, dead battery, or clogged fuel filter.

- Loss of power during use – Possible causes include a dirty air filter, clogged fuel lines, or engine issues.

- Poor cutting performance – This might be caused by dull blades, improper tensioning, or low fuel efficiency.

- Excessive vibration – A loose or damaged component can lead to unstable operation.

Steps for Effective Troubleshooting

Here are a few steps to help you identify and resolve the issue efficiently:

- Check the fuel and oil levels to ensure they are sufficient and properly mixed.

- Inspect the ignition system for any signs of damage or wear.

- Examine the cutting mechanism and ensure it is properly adjusted and sharp.

- Look for any loose parts or signs of damage to internal components.

- Test the starter mechanism to ensure smooth operation.

By systematically addressing these common issues, you can quickly restore your tool to proper working condition, avoiding unnecessary delays or costly repairs.