Knowing the structure and individual elements of your machinery is essential for effective maintenance and repair. Having access to a detailed guide that highlights each section makes it easier to troubleshoot issues and perform replacements. This information serves as a map, helping you locate parts quickly and accurately.

Accurate identification of each component ensures that replacements are done properly, preventing further damage and extending the lifespan of your equipment. This resource is designed to simplify the process, offering clear references to assist both beginners and experienced users.

Familiarity with these details not only saves time but also reduces the need for professional assistance. By understanding how each part interacts, you can handle most maintenance tasks independently, improving the efficiency and longevity of your tools.

Understanding the Craftsman 917 Diagram

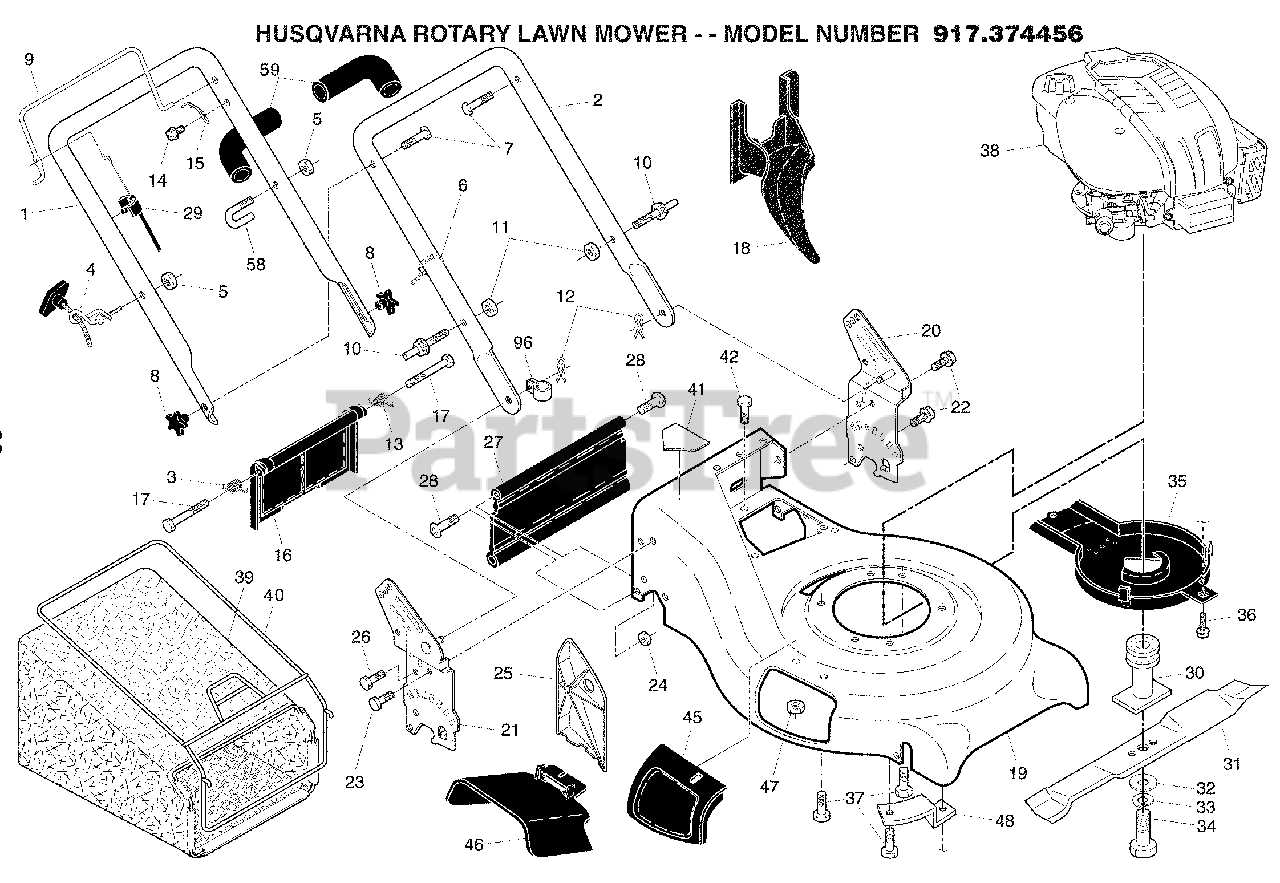

Having a clear and detailed guide for your equipment’s layout is crucial for effective troubleshooting and maintenance. These resources help users familiarize themselves with each section, ensuring that they can identify any issue that might arise. A comprehensive visual reference acts as a map, allowing you to quickly understand the structure of your machinery.

Such a guide provides clarity by visually showing the placement of each component. This makes it easier to assess the functionality of individual elements and locate any parts that require attention or replacement. With accurate depictions, users can confidently work through problems without wasting time searching for solutions.

When using these visual aids, it’s important to not only focus on individual pieces but to understand how they work together. Each part serves a specific purpose, and knowing how they interact will enable you to perform repairs and maintenance tasks with greater efficiency and precision.

How to Identify Key Parts

Accurately recognizing the critical components of your machinery is a fundamental step in ensuring its proper functioning. Whether you are conducting a routine check or troubleshooting an issue, understanding which elements are essential and how to identify them will make maintenance much easier. These key parts often require attention due to wear and tear, making it essential to locate them quickly.

Visual Inspection

Start by visually inspecting the equipment, focusing on the most visible components. Look for any signs of damage or excessive wear that could affect performance. Common areas to check include belts, gears, and connecting parts. Understanding the function of each section helps in pinpointing the key pieces that need maintenance.

Referencing Your Manual

Once you’ve identified the key areas, use a detailed manual or guide to cross-reference and verify the components. These resources provide clarity on part names and positions, making it easier to replace or repair specific sections. Familiarize yourself with the terminology used in the guide to avoid confusion during future maintenance tasks.

Benefits of Accurate Parts Replacement

Replacing damaged or worn components correctly is essential for maintaining the overall efficiency and longevity of your equipment. When you choose the right replacements and install them properly, you ensure that the machinery operates smoothly, reducing the likelihood of further issues. This process also helps maintain safety standards and prevents unnecessary downtime.

One of the key benefits of precise component replacement is the improved performance of your machinery. Properly fitted pieces function optimally, leading to better results and fewer breakdowns. Additionally, it contributes to cost savings by avoiding frequent repairs or the need for a complete overhaul.

Another important advantage is extended durability. By using high-quality replacements and ensuring correct installation, you increase the lifespan of your equipment. This means fewer interruptions and a more reliable operation, which is crucial for maintaining productivity and minimizing repair expenses over time.