Understanding the internal components of your lawn equipment is crucial for proper maintenance and effective repairs. With the right knowledge, you can easily identify parts and troubleshoot issues that might arise during operation. This guide offers a detailed breakdown of the key components of a typical lawn tractor, helping you maintain its peak performance.

Knowing where each element fits into the larger system can save you time and effort when making adjustments or replacements. A well-organized reference can simplify the repair process, allowing for faster and more efficient solutions. Whether you’re dealing with a minor malfunction or preparing for routine servicing, having a clear visual reference is invaluable.

Understanding the Key Components of Your Lawn Tractor

Every lawn tractor consists of a variety of interconnected components that work together to ensure smooth operation. From the engine to the steering mechanism, each part plays a vital role in maintaining the machine’s efficiency. Familiarizing yourself with these essential elements is crucial for anyone looking to properly maintain or repair their equipment.

The drivetrain, engine, and transmission system are the core components that enable movement and power delivery. By understanding how these parts interact, you can better diagnose performance issues or identify areas requiring attention. Other components such as the fuel system, electrical wiring, and control systems also contribute to the overall functionality, and knowing their locations and purposes is essential for any repair task.

Having a clear mental map of these systems not only makes repairs easier but also helps in identifying potential wear and tear that could affect the tractor’s longevity. Being proactive in maintaining these components can prevent future breakdowns and ensure that your machine continues to perform at its best throughout the year.

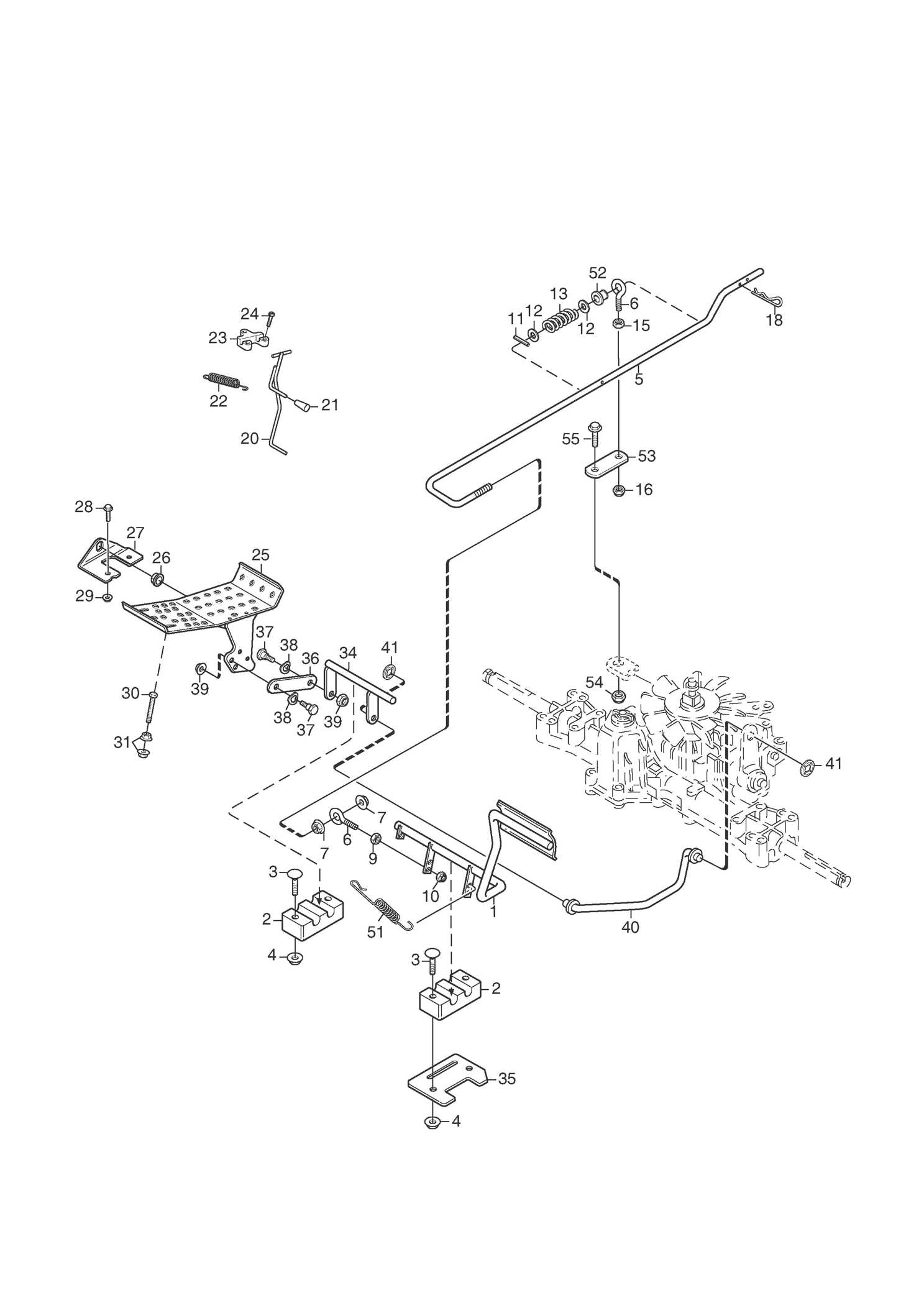

How to Read the Component Layout

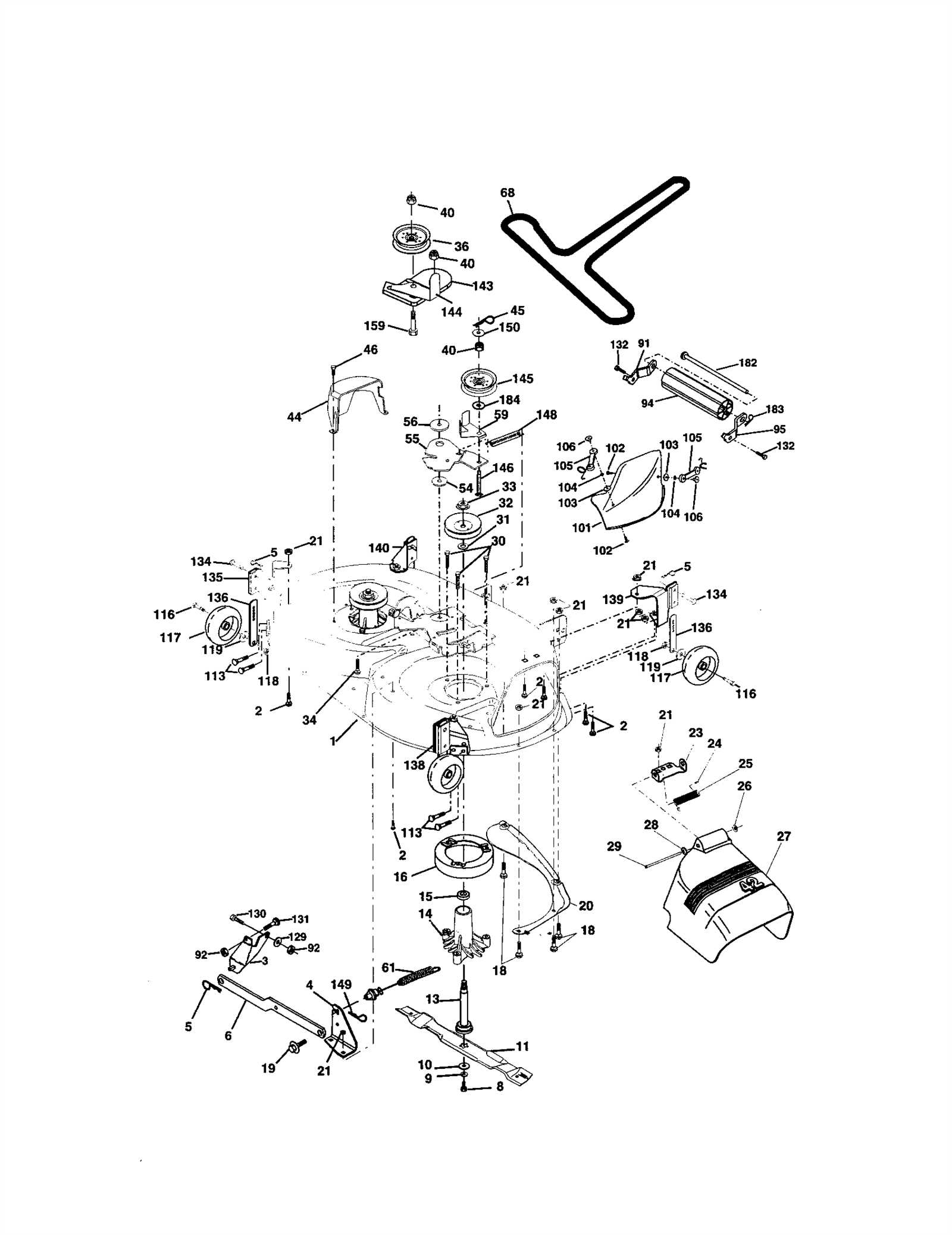

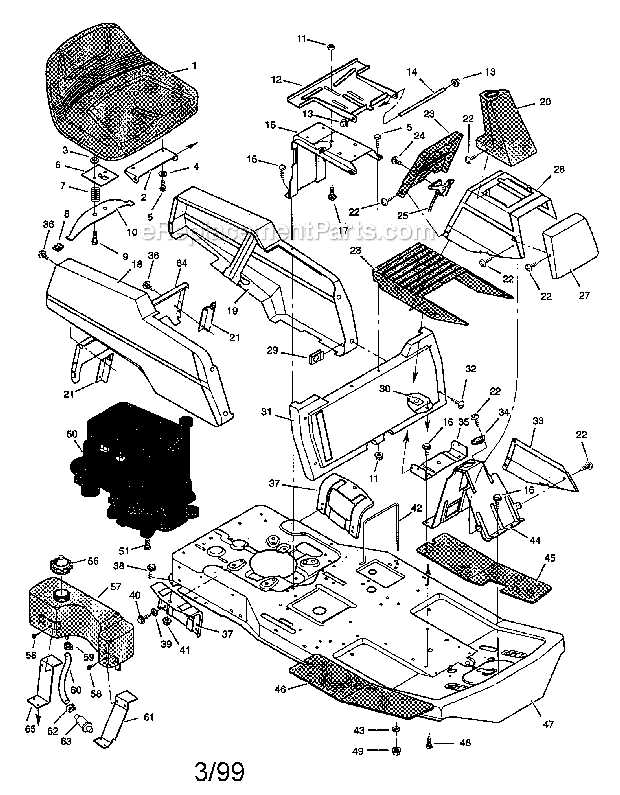

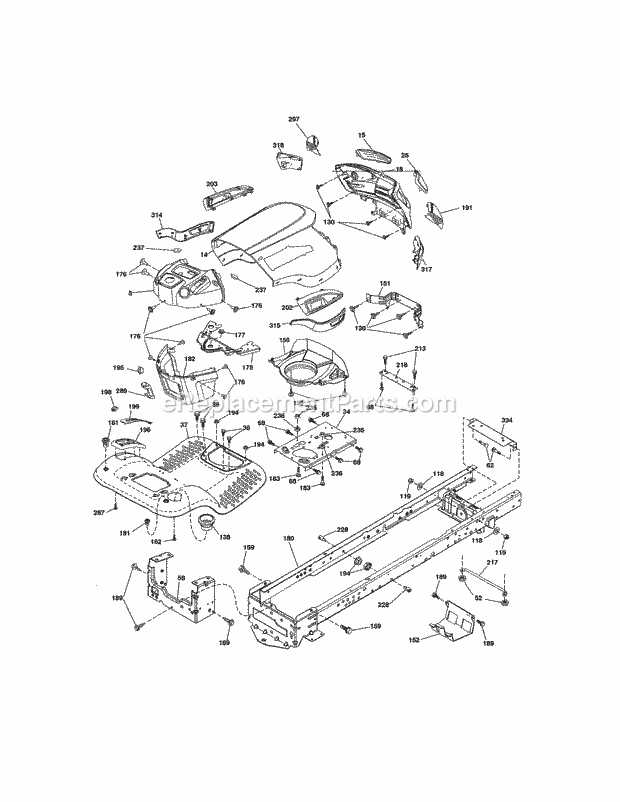

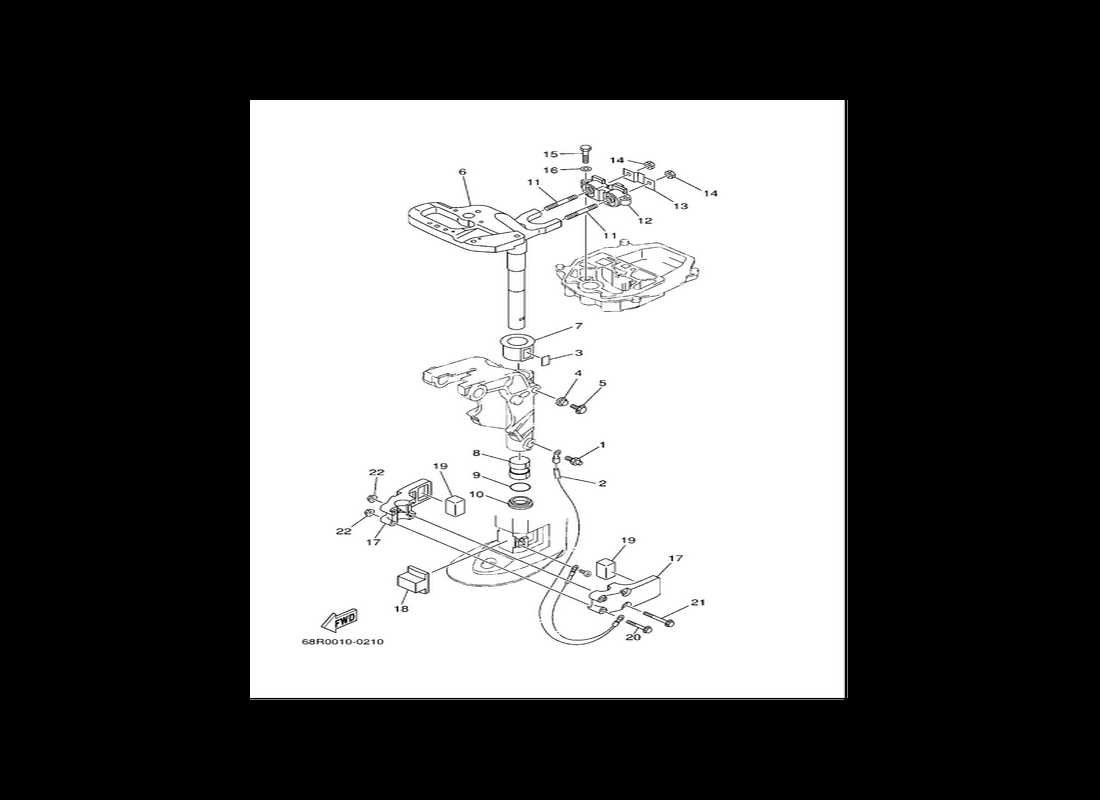

Understanding how to interpret the layout of various machine elements is essential for troubleshooting and repairs. By familiarizing yourself with these visual guides, you can quickly locate parts, identify issues, and make more informed decisions about replacements or adjustments.

Here are some key steps to effectively read the visual representation of your equipment:

- Identify key sections: The layout is typically divided into distinct zones that correspond to different machine systems, such as the engine, transmission, and electrical components.

- Understand part numbering: Each element is assigned a unique number, which helps in easily locating and referencing specific components when ordering replacements or consulting manuals.

- Look for connection points: The diagram will show how different parts connect or interact with each other, giving insight into how they work as a unified system.

Additionally, some diagrams may include color coding or shading to emphasize areas of particular importance, such as high-stress components or those requiring regular maintenance. This makes it easier to prioritize attention when performing inspections or repairs.

Common Issues and Solutions for Lawn Tractors

Lawn equipment often encounters certain recurring problems that can affect performance. Understanding these common issues allows you to address them quickly and avoid unnecessary downtime. Recognizing symptoms early and applying simple solutions can ensure your machine continues to run smoothly throughout the season.

One frequent issue is engine failure to start. This can be caused by a variety of factors, including a dead battery, faulty spark plugs, or issues with the fuel system. Checking the battery voltage and inspecting the spark plugs for wear can quickly pinpoint the issue. Additionally, ensuring that fuel is fresh and free of debris is essential for proper engine function.

Another common problem is difficulty in steering or handling. This may arise from worn-out belts, a malfunctioning steering mechanism, or improperly inflated tires. Inspecting the steering system for loose components and ensuring belts are tensioned correctly can resolve these issues. Additionally, maintaining the right tire pressure improves maneuverability.

Lastly, overheating can occur if the cooling system is obstructed or if oil levels are low. Regularly checking and changing the oil, along with cleaning the cooling system, will help prevent this issue from affecting performance. Keeping these areas well-maintained will extend the life of your equipment and keep it running efficiently.