Maintaining and repairing any lawn equipment requires a clear understanding of its internal structure. Knowing where each individual piece fits and how they interact with one another is crucial for successful repairs. This guide will help you navigate through the layout of the key components of your machine, ensuring you can make informed decisions when fixing or replacing parts.

Whether you’re troubleshooting issues or performing routine maintenance, having a comprehensive visual reference can make a world of difference. It eliminates the guesswork and allows for a more systematic approach to dealing with mechanical problems. Understanding the connection between different elements also ensures that repairs are done safely and effectively.

With the right visual aid, even the most complex machinery becomes manageable. You’ll be able to identify damaged parts quickly, order replacements, and complete repairs without unnecessary delays. In the following sections, we’ll break down the most important components and how to use this information for efficient maintenance.

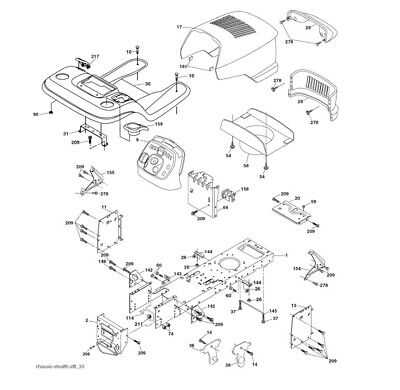

Understanding the Tractor’s Component Layout

Having a clear visual representation of a machine’s structure can greatly simplify maintenance and repair tasks. By examining how each element fits into the overall assembly, you gain valuable insight into how the system functions. This helps in identifying faulty or worn-out components that need attention. A thorough understanding of the layout allows for easier navigation during repairs, ensuring efficiency and accuracy.

Identifying Key Elements and Their Functions

Each part within the assembly has a specific role, whether it’s a mechanical, electrical, or structural function. Knowing what each piece does helps prioritize which areas need attention. Some components might be more prone to wear and tear, while others contribute to the overall performance of the machine. Recognizing these differences aids in troubleshooting and decision-making when it comes time to replace or repair a specific part.

How to Use the Layout for Repairs

When dealing with repairs, it’s crucial to understand how each part interacts with others. This knowledge allows you to approach the task step by step, ensuring that no part is overlooked. By following the layout closely, you can easily pinpoint the problematic area, order the correct replacements, and efficiently restore the equipment to working condition. This systematic approach reduces errors and helps avoid unnecessary replacements or repairs.

Key Components of the Tractor Model

Every machine is built with essential components that work together to ensure its proper functionality. These key elements, whether mechanical or electrical, are vital for smooth operation. Understanding the role of each part is critical for effective maintenance and troubleshooting. This section highlights the most significant components and their contribution to the overall performance.

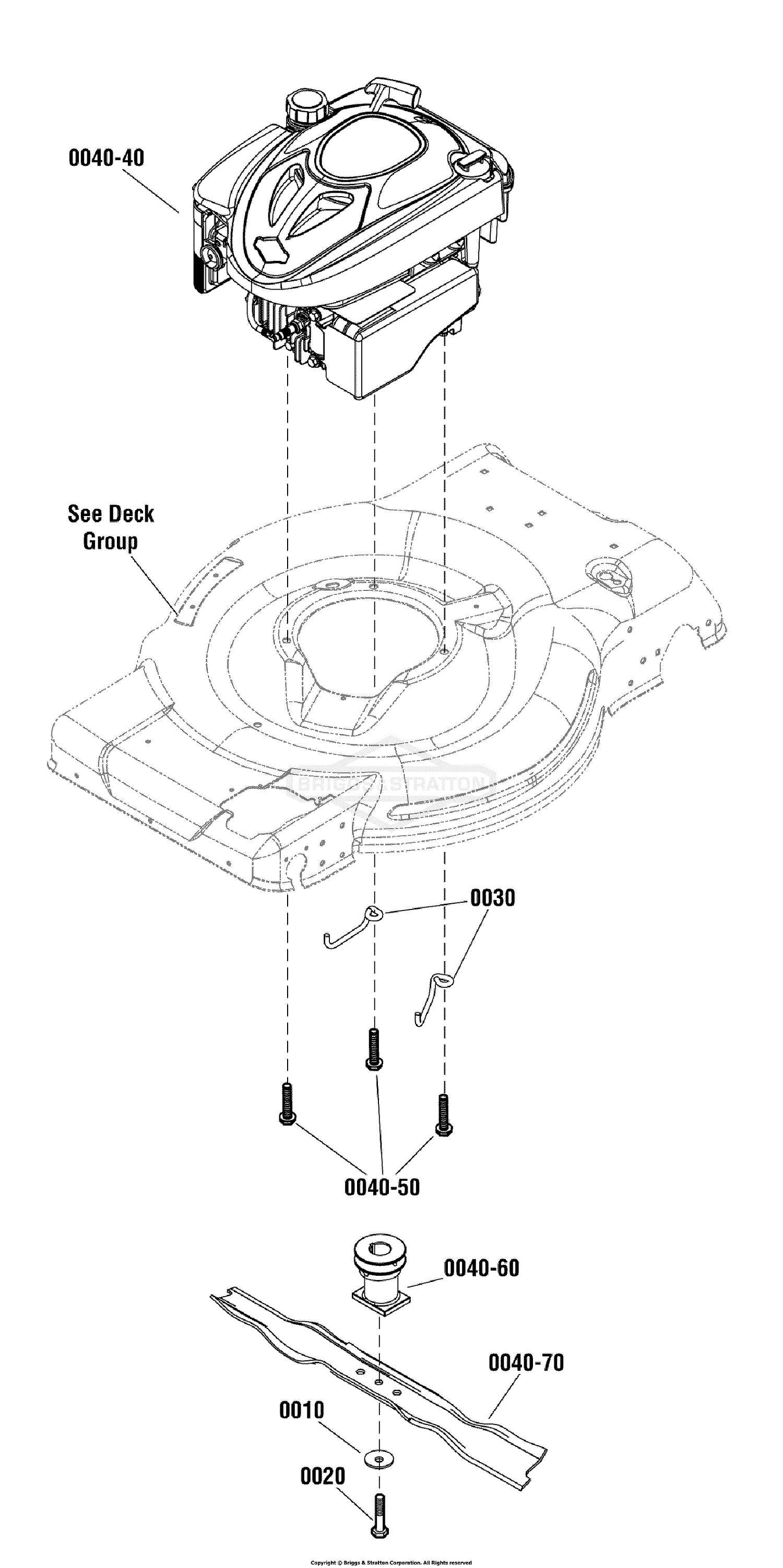

Engine and Power Transmission

The engine is the heart of any machine, providing the necessary power to drive various functions. It works in tandem with the power transmission system, which transfers energy to the wheels and other moving parts. Proper maintenance of these components ensures optimal performance and longevity. Regular checks for oil levels, fuel filters, and air intake are essential for keeping the engine running smoothly.

Steering and Control Systems

The steering and control mechanisms are responsible for directing the machine’s movement and responding to operator input. This includes the steering wheel, linkages, and drive controls that allow precise adjustments. These systems require periodic inspection to ensure no wear or damage to key linkages, which could affect maneuverability. Lubrication and alignment are crucial for maintaining smooth and responsive operation.

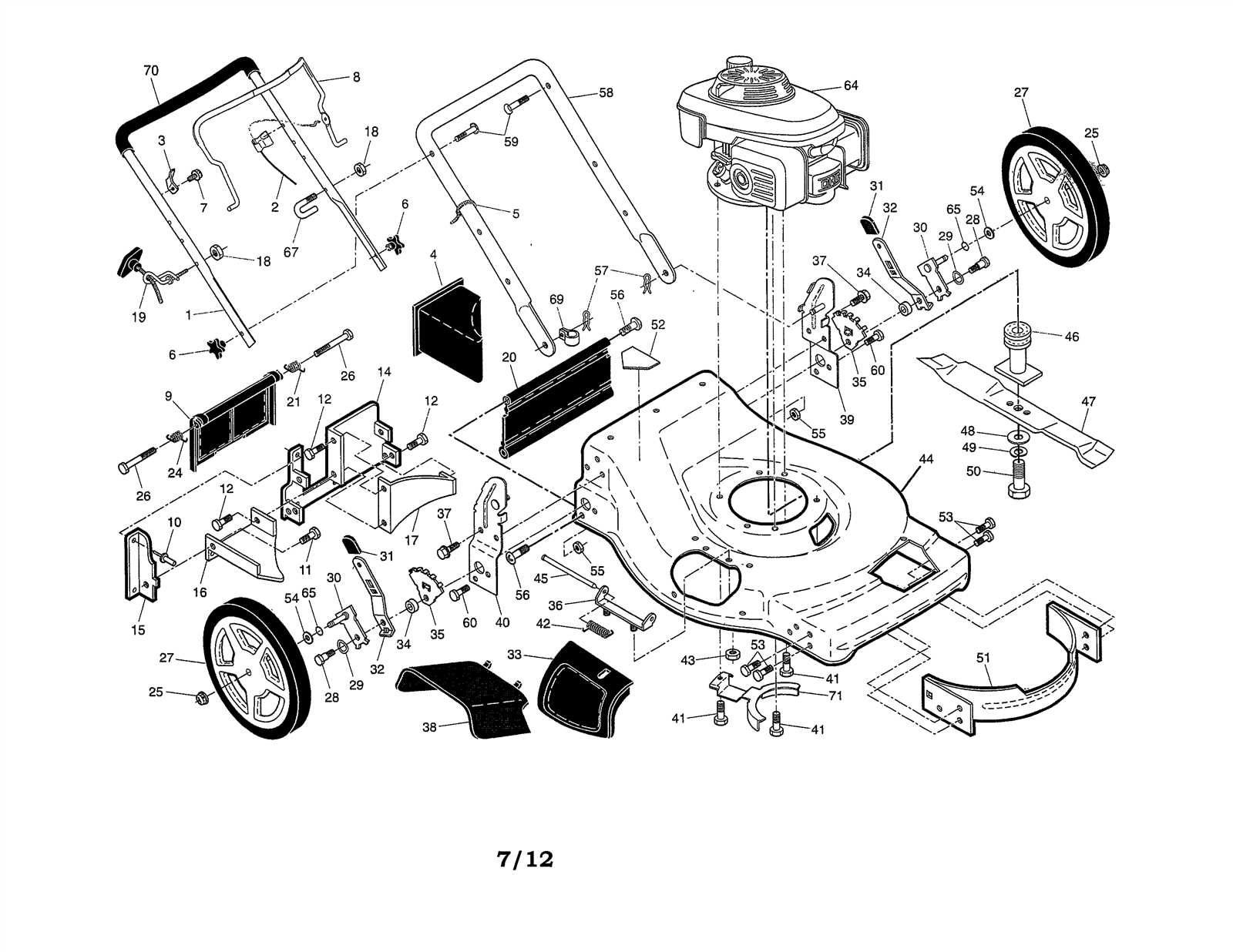

How to Use the Layout for Repairs

Understanding the internal structure of your machine is crucial when it comes to repairs. A clear layout allows you to identify and locate damaged components quickly, saving both time and effort. By referencing the visual guide, you can determine which parts need attention and how they interact with other systems, helping you plan your repair steps more effectively.

Step-by-Step Process for Efficient Repair

Begin by identifying the area where the issue has occurred. Once located, use the layout to find the corresponding components and examine them for damage or wear. Follow the connections between parts to understand their relationships. Using this reference, you can ensure that you replace only the necessary parts, avoiding unnecessary replacements and minimizing repair costs.

Tips for Accurate Part Replacement

When replacing a faulty component, be sure to select the correct replacement from a reliable supplier. Double-check the specifications to ensure compatibility with your machine. Aligning the new part properly and securing it in place is key to restoring functionality. The visual guide can also help you understand the exact orientation and connections of the replacement components, ensuring a proper fit.