When maintaining or repairing any type of machinery, it’s crucial to have a clear understanding of its internal components. This knowledge can help prevent costly mistakes and improve the overall efficiency of the machine. Identifying each element and understanding its role within the system is the first step towards effective maintenance and troubleshooting.

In this guide, we will explore how to interpret a detailed layout of machine components, providing you with the necessary tools to identify, replace, and maintain the essential parts. With the right approach, you’ll be able to keep your equipment in top working condition for years to come.

Understanding Machine Components

When dealing with complex machinery, having a comprehensive understanding of its internal structure is essential. Each element plays a crucial role in ensuring smooth operation, and knowing how these components work together can prevent issues from arising. Whether for maintenance or repair, being familiar with the layout of key components can make a significant difference in keeping the equipment running efficiently.

Key Elements of a Typical Machine

The essential parts that contribute to the functionality of any machine can be divided into several categories. Each component has its own specific function, from powering the engine to ensuring the stability and movement of the entire system. Knowing where these parts are located and how they interact can help streamline repairs and upgrades.

Why Component Understanding Matters

Having a solid grasp of the various elements and their roles within the machinery can lead to improved maintenance practices and a longer operational life for the equipment. Proper identification of worn or damaged components helps in making informed decisions about replacements or repairs, preventing unnecessary downtime.

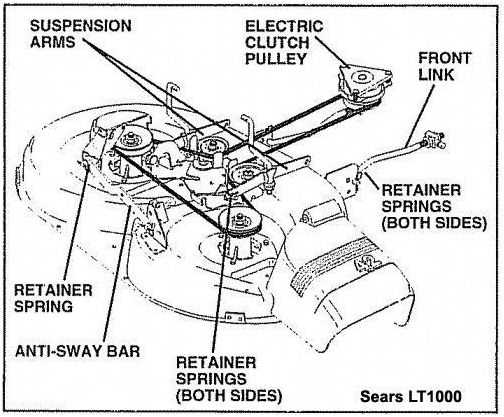

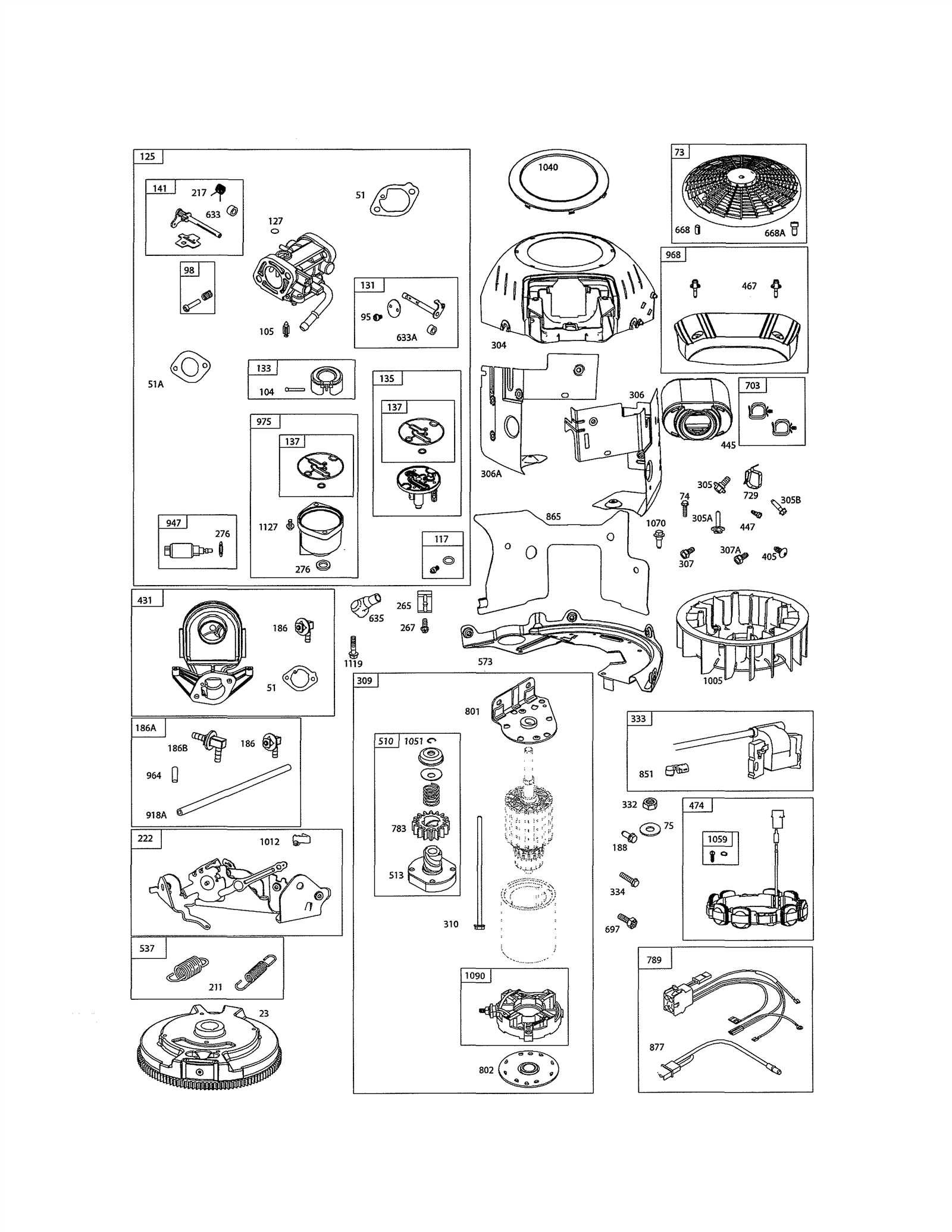

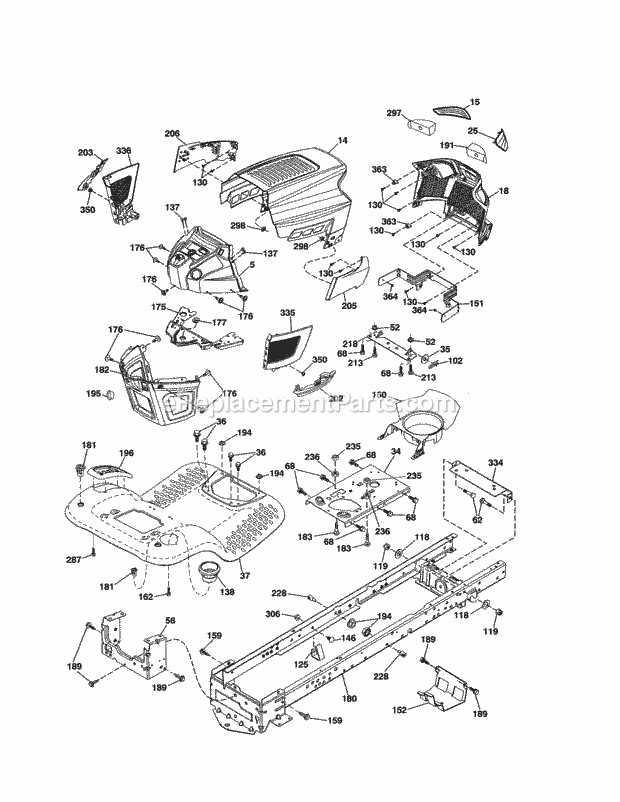

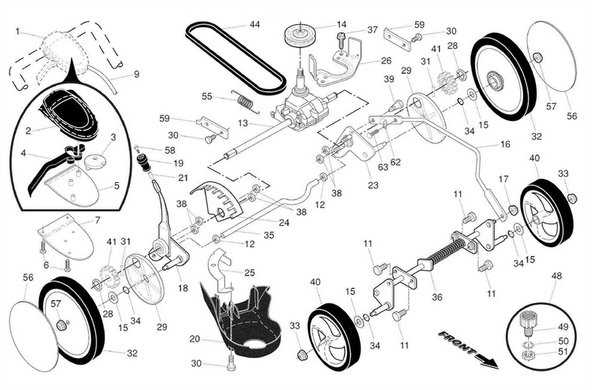

How to Use the Parts Diagram Effectively

Having a visual representation of the components within a machine is a valuable tool for anyone working on repairs or maintenance. By referring to such a guide, you can quickly locate and identify the specific elements that need attention. This method allows for a more precise and efficient approach when handling any issues that arise.

To use this guide effectively, start by familiarizing yourself with the layout and labeling system. Understanding how each component is arranged and named helps you pinpoint the exact parts that require replacement or adjustment. Once you’re confident in navigating the visual representation, you can begin troubleshooting specific problems with greater ease and accuracy.

Common Issues with Machines

Every machine, no matter its complexity, can experience issues over time. These problems can range from minor inconveniences to more serious malfunctions that require immediate attention. Recognizing the signs of common problems early can help prevent further damage and reduce repair costs.

Some typical challenges include engine performance issues, where the machine may struggle to start or run smoothly. Additionally, wear and tear on essential components can lead to reduced efficiency or even complete failure of certain functions. Regular maintenance and prompt troubleshooting are key to extending the life of the equipment and ensuring it operates at its best.