When it comes to tree maintenance, having a clear understanding of your equipment is essential. Proper knowledge of each component ensures smooth operation and longevity of the tool. Whether you’re a professional or a DIY enthusiast, being familiar with the specific parts will help you troubleshoot issues and perform regular upkeep effectively.

In this section, we will delve into the key elements of your cutting equipment. From the blade to the handle, understanding how each piece functions together is crucial for maintaining peak performance. Maintenance and repair become much easier when you can identify and replace faulty components with ease.

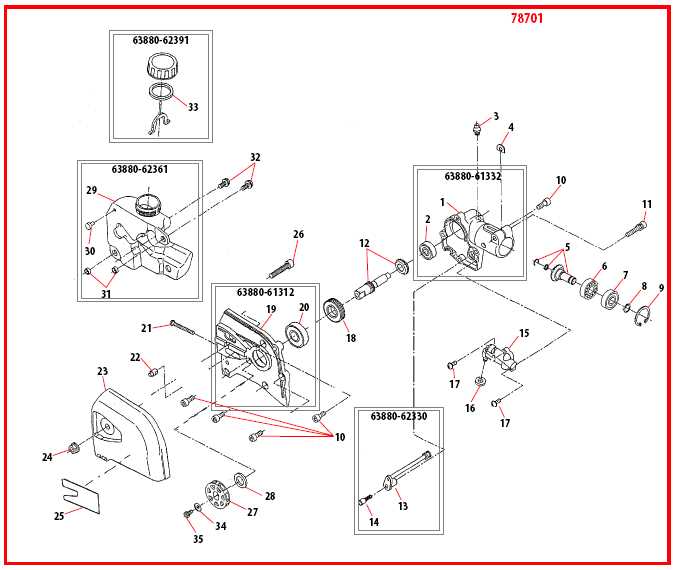

Understanding Craftsman Pole Saw Components

To ensure your tree-trimming tool operates smoothly, it’s essential to recognize the individual elements that contribute to its performance. Each component plays a vital role in ensuring the tool is functional, durable, and efficient. By understanding these features, you can quickly identify any wear or damage, allowing for easier repairs and maintenance.

Key Functional Elements

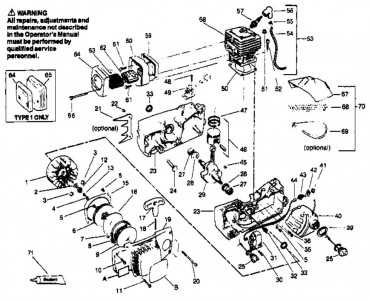

The main segments of your cutting device include the power source, cutting mechanism, and extension system. The power source drives the blade, enabling it to cut through branches effectively. The cutting mechanism, typically a sharp, durable blade or chain, is what directly engages with the material. Meanwhile, the extension system allows you to reach higher branches, making it an essential feature for trimming tall trees with ease.

Maintenance and Troubleshooting

Regular inspection and maintenance of the tool’s components are necessary to extend its lifespan. Key areas to monitor include the motor, the cutting surface, and the connectors between parts. If any component becomes loose or damaged, it can affect the overall function of the device, potentially leading to safety hazards or performance issues. Understanding how these elements work together simplifies the process of detecting and addressing any problems that may arise.

How to Identify Pole Saw Parts

Recognizing the individual components of your tree-trimming equipment is crucial for maintenance and troubleshooting. By familiarizing yourself with each piece, you can easily spot issues and ensure smooth operation. Identifying the right elements will also help when searching for replacement items or seeking professional assistance.

The following list highlights the main components commonly found in these tools:

- Power Unit: The motor or engine that drives the cutting mechanism.

- Cutting Mechanism: The blade or chain that performs the trimming.

- Extension Shaft: The long pole or shaft that allows you to reach higher branches.

- Handle: The part you grip to control and maneuver the tool.

- Safety Features: Guards or switches designed to protect the user during operation.

Each of these elements plays an integral role in the overall function. Familiarizing yourself with their structure and location will make the identification process much simpler when performing repairs or replacements.

Step-by-Step Craftsman Saw Maintenance

Proper upkeep of your tree-cutting tool ensures long-lasting performance and safe operation. Regular maintenance not only prevents wear and tear but also helps you spot potential issues before they become costly repairs. Following a clear maintenance routine will keep your equipment in top condition, ready for every trimming task.

Here is a step-by-step guide to maintaining your tool:

- Clean the Cutting Mechanism: After each use, thoroughly clean the blade or chain to remove sap, dirt, and debris. This helps prevent rust and keeps the cutting surface sharp.

- Inspect the Motor: Check the motor for any signs of damage, dirt buildup, or wear. Ensure it is properly lubricated and free from obstructions.

- Check the Extension Shaft: Make sure the extension mechanism is functioning smoothly. Look for any loose connections, cracks, or signs of damage.

- Test the Safety Features: Ensure all safety guards, switches, and mechanisms are intact and working properly. Safety is a priority, so double-check these before each use.

- Lubricate Moving Parts: Apply lubricant to the joints and moving components regularly to keep everything functioning smoothly.

By following these simple steps, you can keep your tool running like new, reducing the need for repairs and extending its overall lifespan.